工具管理

阀门外壳 EN-GJS-400-15 - 完整加工

刀具管理系统用于大批量生产包括单件成本(CPP)核算和最大生产率的提高

刀具管理系统用于大批量生产包括单件成本(CPP)核算和最大生产率的提高

客户的初始情况

- 库存量高

- 刀具预调间中的工艺流程并非最优的和数据质量不完整

- 成本透明度不足够

- 专业人员普遍短缺造成较大的人力波动现象

- 发生断刀的问题

- 刀具成本高

UNIBASE 软件

- 使用应用程序进行外部存取的网页界面

- 可选连接到开放的、基于云端的C-Com平台

- 综合评估选项

- 仅点击几次即可取出产品

- 永久的、自动的库存监控

- 可以连接到现有的ERP系统

UNIBASE-M

- 刀具、组件和配件的理想存储系统

- 有针对性地取出单个零件的刀具出入库管理限制

- 可变抽斗分区

UNIBASE-V

- 完全组装好刀具的安全存放

- 长型刀具的直立仓储

- 对切削刃无风险

- 立式控制柜带有滚轮导向的拉出装置

- 可以集成到现有系统中

- 在刀具管理项目中已久经考验

UNIBASE-C

- Single dispensing system

- Storage of small and individual parts

- Single dispensing increases theft protection

- Ready for use as a single solution or in existing systems

Billing options

After withdrawal

With this billing model, you receive one invoice with all the tools used at the end of the month. Your procurement effort and your financial bookkeeping are significantly simplified as a result.

Cost per part

You remain particularly flexible and are guaranteed annual savings. With this model the tool costs per part produced are calculated. This option ensures optimal cost distribution with fluctuating volumes.

Advantages

- Using up of excess inventory

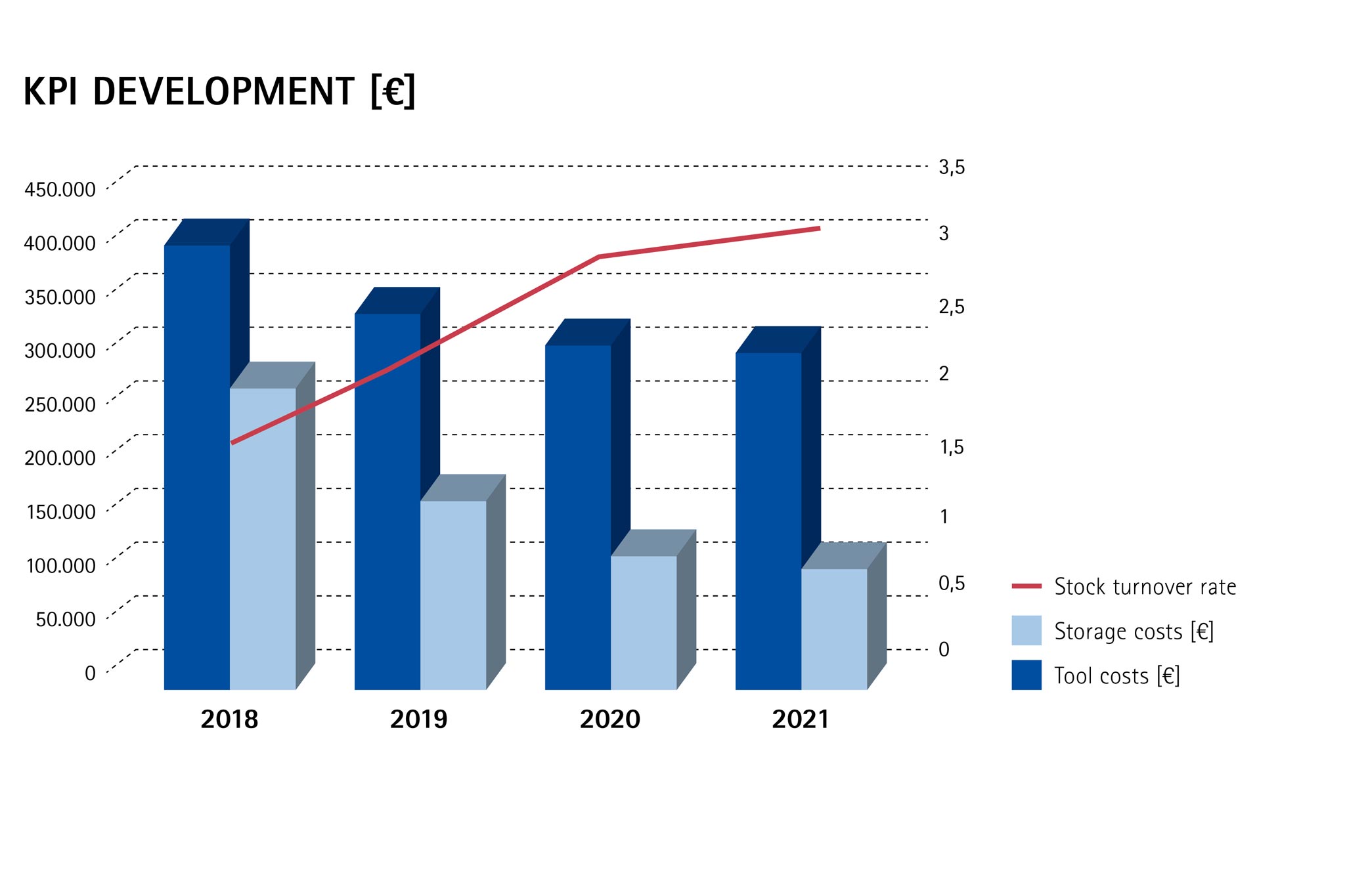

- Cost transparency

- Latest tool technologies

- Reduced tool variety and standardisation

- Tools are provided on the machine by MAPAL personnel

- Constant tool use

- Predictable and consistent tool costs due to billing based on costs per part (CPP).