07.12.2022

Learning to connect

Gewerbliche Schule Göppingen taps into MAPAL’s digitalisation know-how

Equipping young people for the world of industry – that’s Gewerbliche Schule Göppingen’s mission. The commercial school teaches vocational students, student technicians and the foremen and women of the future. Their curriculums are adapted to current challenges – with digitalisation and industry 4.0 among the key themes. The school draws on MAPAL’s products and know-how to offer the best learning environment in its own centre of competence for machining technology.

The ideal setting fixture for the school

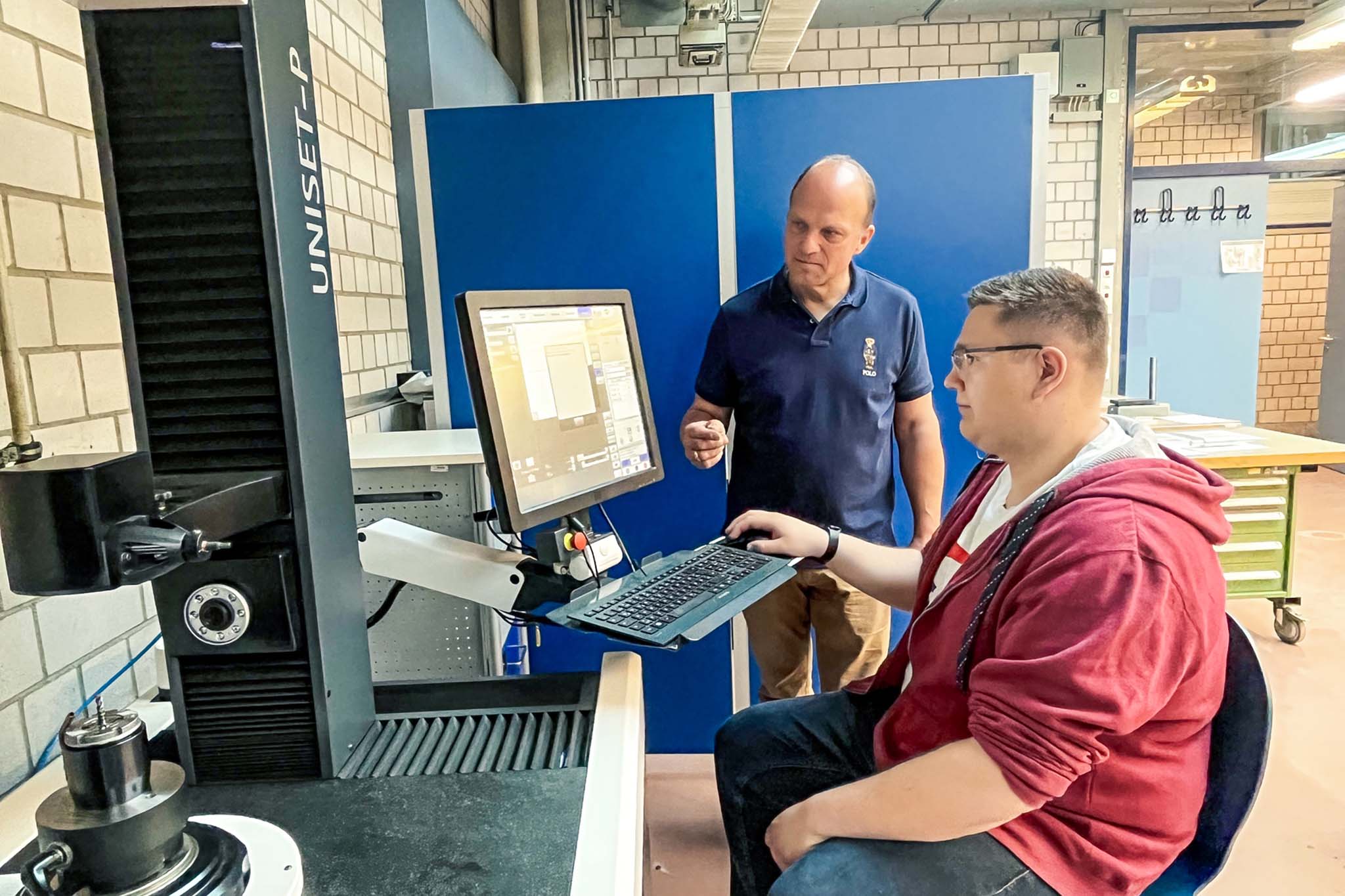

When it was time to acquire a setting fixture at the GS, Wöhrle therefore took MAPAL into consideration as a supplier. “To make a sound decision, I commissioned a technical thesis project. One of our budding technicians compared various setting fixtures and worked out the best device for us,” explains Wöhrle. Sven Frank, Global Head of OEM Management at MAPAL, recalls: “The GS request for a setting fixture landed on my desk. Of course, we produced the right offer for the school.” MAPAL selected a UNISET-P equipped with many different features. “As it was a refurbished return model, we were able to offer it at an unbeatable price,” explains Frank. After all, he says, it’s incredibly important for the company to support young people’s education and training. “If the newly qualified cutting machine operators, technicians and foremen and women remember our equipment in their businesses and become customers, that’s a win for us,” says Frank.

How the data is passed from the setting fixture to the machines and which solutions the market offers for this, also formed part of the technical thesis project. The setting fixture’s properties were therefore not the only reason the technical thesis project ended up deciding a MAPAL device was the best solution for the GS. “MAPAL’s digitalisation know-how impressed us,” says Wöhrle. “Digitalisation and industry are huge topics for us. They’ve been an integral part of the curriculum for four years. For instance, we equip our technicians with iPads.”

Integrating machines into the system

Computer Aided Manufacturing (CAM) is part of every curriculum at the GS – for vocational students, student technicians and future foremen and women alike. Accurate data and integrating machines into the overall system are correspondingly important. For privacy reasons, however, machines and setting fixtures at the GS cannot be connected to the school network. “Our machines are from 2010 – they didn’t have the prerequisites for connecting them to our system anyway,” adds Wöhrle.

MAPAL therefore offers a solution alongside the UNISET-P that nevertheless allows machines to be connected to the setting fixture: barcode labels for the tools are printed on the UNISET-P. c-Connect boxes with scanners are connected to the machines in the centre of competence. This allows the barcodes to be scanned and labels to be read. The c-Connect boxes, which connect to the machine via USB, transfer the data.

“The solution is incredibly simple and works brilliantly for us. It’s easy to use, we don’t have to make complicated interventions in machine control, and the costs were well within budget,” says Wöhrle with satisfaction. The machine operators – in this case, the school’s students – no longer need to manually input anything into the machine.

GS maps out the entire machining process

The results of a variety of project tasks that Harald Wöhrle set his students demonstrate how intensively cutting machine operators, technicians and foremen and women work with the setting fixture and c-Connect boxes today. Accordingly, a variety of different text and video guides on the setting fixture and how it is used at the GS have been created.

The setting fixture also fulfils its duties from a practical perspective. “Before the students machine their workpieces, they equip the machine accordingly. Before that, they measure the tools and adjust them if necessary. They transfer the data into the CAM system and simulate machining. Only then do they move onto actual machining at the machine.” Just like in all manufacturing. Harald Wöhrle is particular proud of this: “We’re mapping out the entire process here – including all calculations.” This is why, for instance, the school operates a cutting database for all teachers and students to access. “That was another technical thesis project in which MAPAL was always on hand to help with any queries and issues,” says Wöhrle.

Plans for tool management

An expansion of the cooperation is therefore planned. “We’d like to build a tool management system, including test equipment management,” says the teacher, looking to the future. “And MAPAL is predestined for that,” says Sven Frank. Sebastian Kreller, Global Head of Tool Management at MAPAL, ran a workshop at the GS to give decision-makers and budding technicians at the GS a glimpse of MAPAL’s tool management options.

“MAPAL has also impressed us in terms of tool management,” says Wöhrle. After all, “unlike with other providers’ dispensing systems and software, at MAPAL, it doesn’t matter what’s being managed. For instance, this would allow us to manage not just all our tools, irrespective of the manufacturer, but also our testing equipment, using UNIBASE software and the associated dispensing cabinets.” A topic that Harald Wöhrle imagines could make a great technical thesis project. Exciting technical thesis projects and other projects are accordingly in the works for the GS in cooperation with MAPAL.

Gewerbliche Schule Göppingen

Contact

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Phone: +49 7361 585 3342