12.01.2023

Basic – Performance – Expert

Werkzeuglösungen für die E-Mobilität

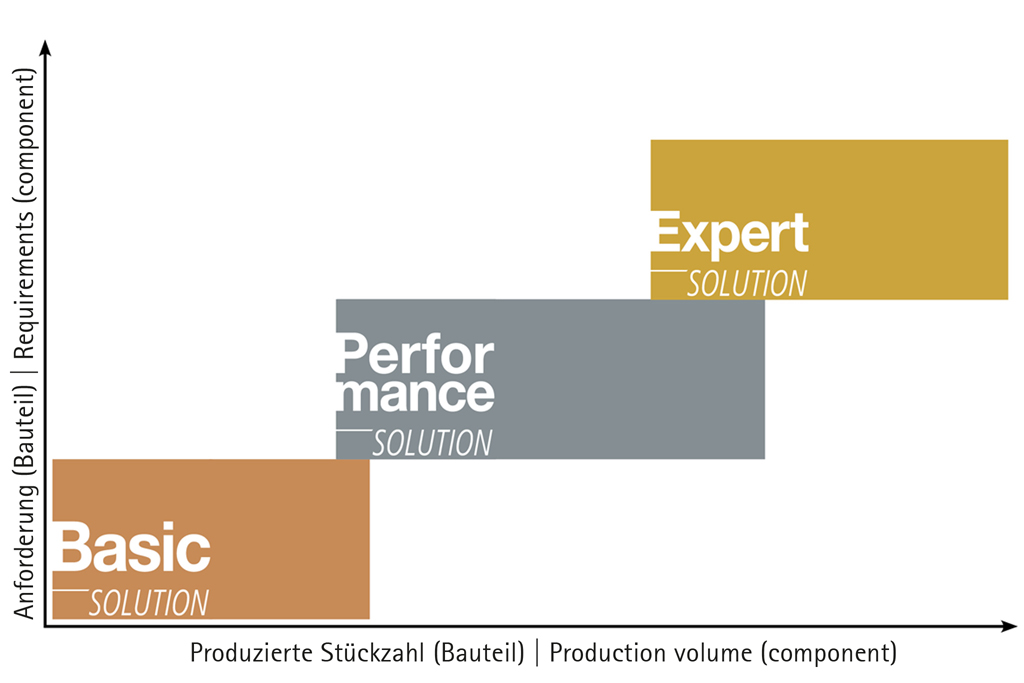

In den kommenden Jahren erwartet MAPAL einen großen Zuwachs bei Zerspanungslösungen für Elektrofahrzeuge. Der Werkzeughersteller hat anspruchsvolle Bauteile in den Fokus genommen, die künftig in hohen Stückzahlen produziert werden. Die neue Klassifizierung Basic-Performance-Expert beschreibt kundenspezifische Lösungen für deren Bearbeitung.

Drei Wege zum Bauteil

Die Basic-Varianten umfassen Lösungen mit Standardwerkzeugen, die kostengünstig die Anforderungen in der Fertigung von Prototypen oder Kleinserien abdecken. Die erforderlichen Investitionen sind vergleichsweise niedrig, und der Werkzeugeinsatz flexibel. Da in dieser Phase oft noch viele Veränderungen an Bauteil und Prozess vorgenommen werden, ist die mit Standardwerkzeugen gewonnene Flexibilität sehr hilfreich. Auf den Einsatz von Sonderwerkzeugen wird in der Basic-Lösung nach Möglichkeit verzichtet.

Die Performance-Lösung ist auf die Serienfertigung ausgerichtet und stellt die Bearbeitung spezifischer Bauteile mit Sonderwerkzeugen in den Mittelpunkt. Das Werkstück kann hier mit Stufen- und Kombinationswerkzeugen effizienter bearbeitet werden als bei der Basic-Variante. Die Performance-Lösung ermöglicht eine prozesssichere und serientaugliche Produktion, ohne bereits die höchsten Anforderungen an Qualität und Produktivität zu erfüllen.

Anspruchsvolle Teile fürs E-Auto

Neben dem elektrischen Antrieb nimmt MAPAL noch weitere Komponenten des E-Autos in den Fokus. Dazu gehören Nebenaggregate wie der Scroll-Verdichter für das Thermomanagement sowie Gehäuse für die Leistungselektronik und Batterierahmen. Für letzteres sind viele Fräsoperationen erforderlich, die ebenfalls gut im dreiteiligen Konzept Basic-Performance-Expert dargestellt werden können. Für Versuche oder kleine Stückzahlen reichen vergleichsweise einfache Standardwerkzeuge. Die nächste Stufe sind spezielle Vollhartmetallwerkzeuge, die mehrere Bearbeitungsschritte zusammenfassen und eine prozesssichere Bearbeitung gewährleisten. Im Performance-Bereich kommen dann Fräser mit speziellen Beschichtungen oder PKD-Fräser zum Einsatz, um die Standzeit auf ein höheres Level zu heben.

Was die optimale Lösung für die jeweilige Anforderungssituation ist, klärt MAPAL im direkten Dialog mit dem Kunden. Der dürfte in vielen Fällen nur zwei der drei möglichen Stufen nutzen. Denn die Prototypenfertigung findet oft bei spezialisierten Zerspanern statt, sodass der OEM direkt mit der Serienfertigung startet. Sind die Qualitätsanforderungen erfüllt und reicht die Produktivität für die zu fertigenden Stückzahlen aus, kommt eine Bearbeitungslösung aus der Performance-Variante zum Einsatz. Sie stellt unter Umständen auch keine so hohen Ansprüche an die Maschinenleistung, was bei der Umrüstung bestehender Linien auf die E-Mobilität ein Kriterium sein kann. Natürlich kann ein Hersteller auch gleich von der Prototypenfertigung auf eine Bearbeitungslösung der Performance-Variante gehen, wenn zum Beispiel ab einem bestimmten Produktionsvolumen die Kosten pro Bauteil im Vordergrund stehen.

Eine offene und zielgerichtete Kommunikation mit dem Kunden steht bei MAPAL seit jeher im Mittelpunkt. Denn nur ein offen geführter Dialog ermöglicht es, für jede Anwendung und jeden Kunden die individuell richtige Werkzeuglösung anzubieten.

Kontakt

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Tel.: +49 7361 585 3342