アクチュエーティングの特長

アクチュエーティングツールは切削加工でも最も高い合理化と最善化の可能性を秘めたツ ールです。お客様の、切削加工のすべてを網羅するツールプログラムが欲しいという要望に 答え、マパールは1990 年代初めからイノベーティブなアクチュエーティングツールやボーリ ングバーとフェーシングヘッドをポートフォリオに加えてきました。専用機で使う場合でも、 フレキシブルなマシニングセンタで使う場合でも - 複雑な輪郭や円筒形でない形状の 穴あけ加工、フェーシングや立方体ワークへのリセス加工にもマパールは最良のツールソリ ューションを提供しています。

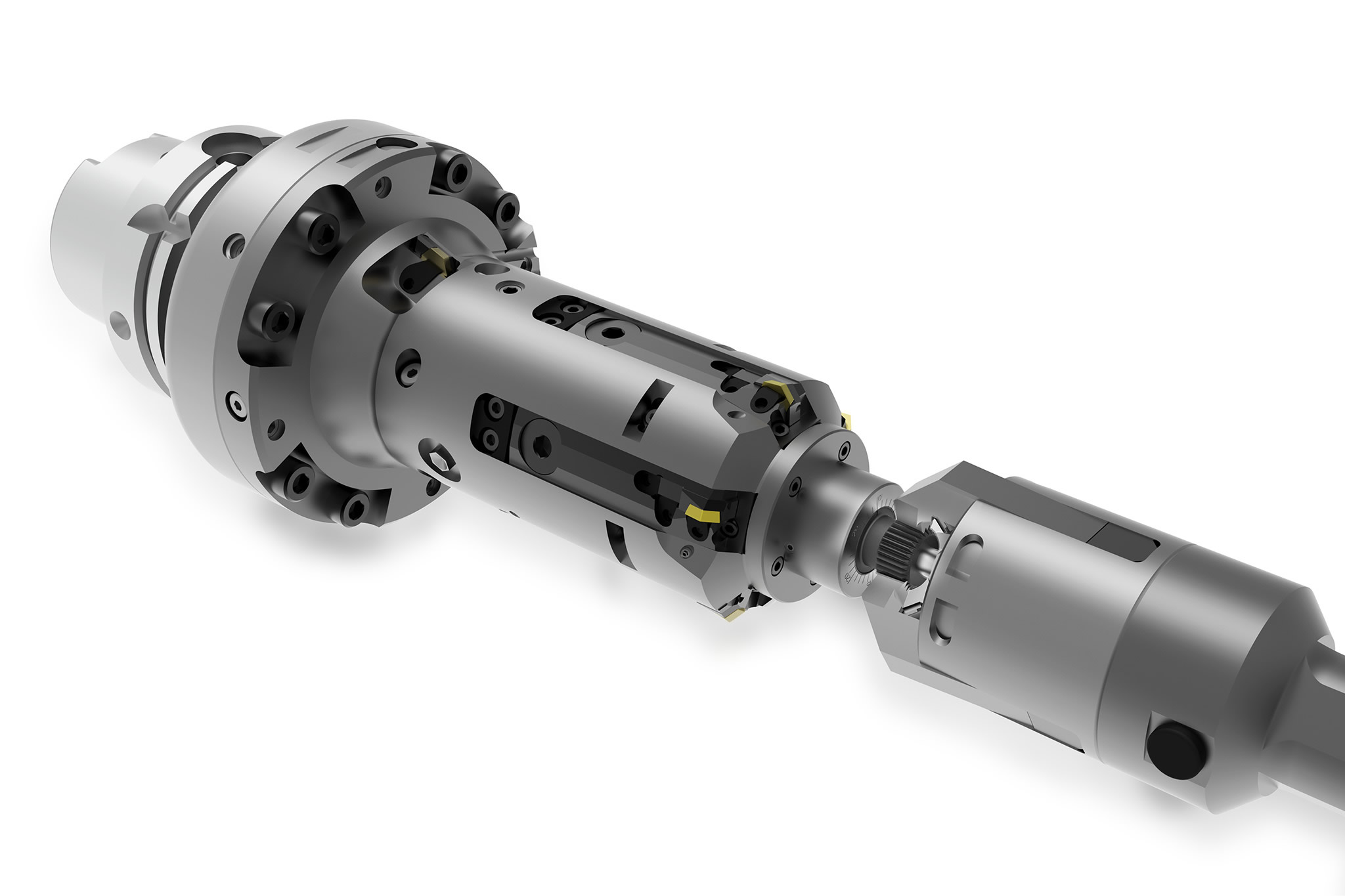

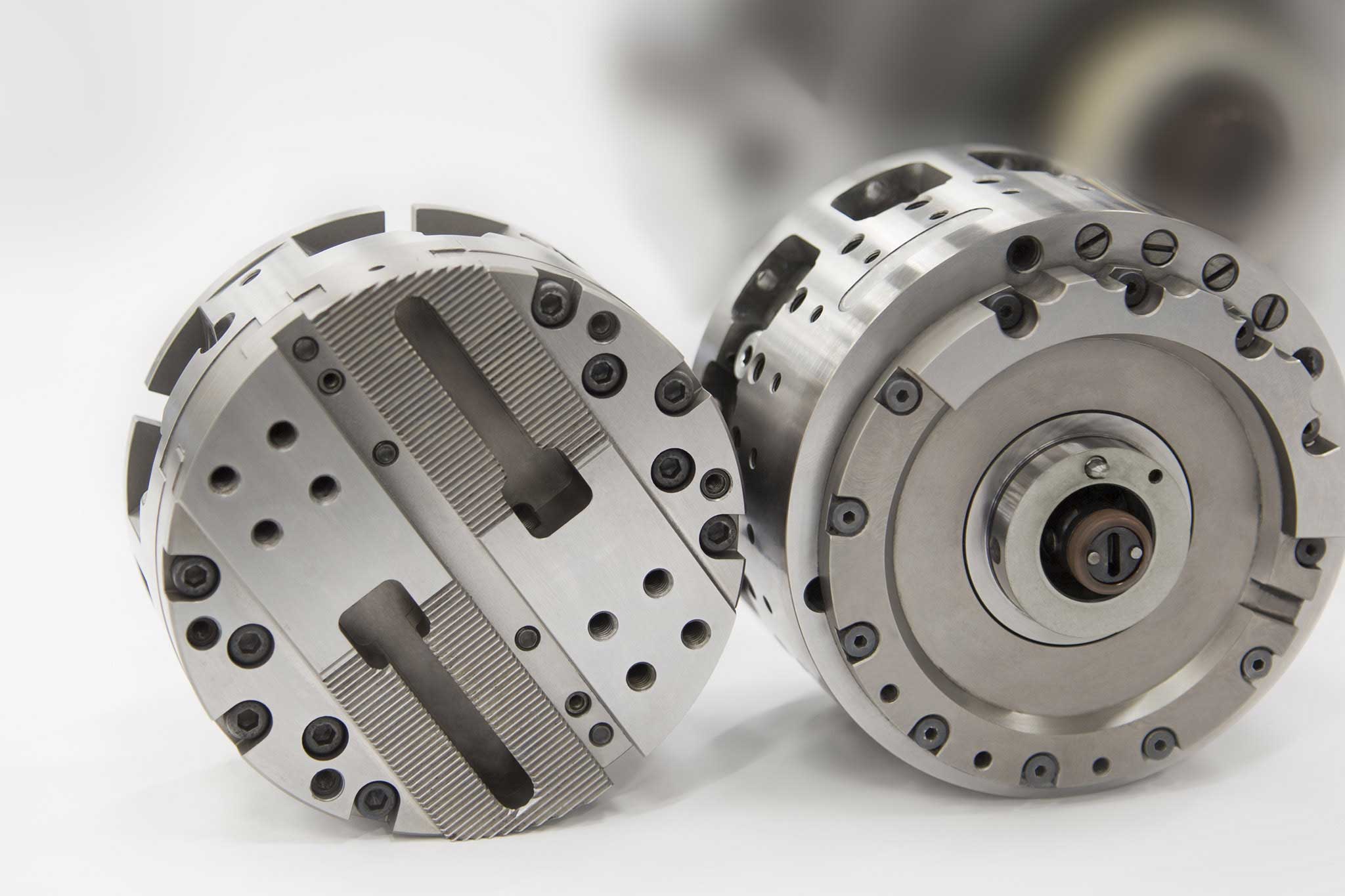

製品のラインナップには、ドローバー/プッ シュロッドまたはU軸システムで駆動され る機械的なアクチュエーティングツールと、 追加のフィードユニットを必要としない特 にフレキシブルなNC制御のメカトロニク ス工具システム TOOLTRONIC があります。 この分野で長年の経験を持つマパールの 高度な専門性をもつエンジニアリングチー ムはお客様と蜜に調整しながら、お客様の切削加工の課題に対する最良のソリューシ ョンを提供してきました。アクチュエーティ ングツールに内蔵される精密に調整された 数多くの構成部品は製造のそれぞれのス テップで最高の精度と最大の注意を払った 作業を要求します。ツールのこの高い精度 を確保するため、マパールでは組み立ては 全て手作業で行っています。お客様の工場 でできるだけスピーディーにそして効率的に運転を開始できるように複雑なアクチュ エーティングツールは事前に当社内で極端 に厳しい負荷のもとと実際の稼働条件でテ スト運転を行っています。お客様の工場で の試運転はマパールの切削加工の専門家 が請負います。

製品のラインナップには、ドローバー/プッ シュロッドまたはU軸システムで駆動され る機械的なアクチュエーティングツールと、 追加のフィードユニットを必要としない特 にフレキシブルなNC制御のメカトロニク ス工具システム TOOLTRONIC があります。 この分野で長年の経験を持つマパールの 高度な専門性をもつエンジニアリングチー ムはお客様と蜜に調整しながら、お客様の切削加工の課題に対する最良のソリューシ ョンを提供してきました。アクチュエーティ ングツールに内蔵される精密に調整された 数多くの構成部品は製造のそれぞれのス テップで最高の精度と最大の注意を払った 作業を要求します。ツールのこの高い精度 を確保するため、マパールでは組み立ては 全て手作業で行っています。お客様の工場 でできるだけスピーディーにそして効率的に運転を開始できるように複雑なアクチュ エーティングツールは事前に当社内で極端 に厳しい負荷のもとと実際の稼働条件でテ スト運転を行っています。お客様の工場で の試運転はマパールの切削加工の専門家 が請負います。

アクチュエーティング時

製品の概要

インプットと アウトプットのタイプ

TOOLTRONIC

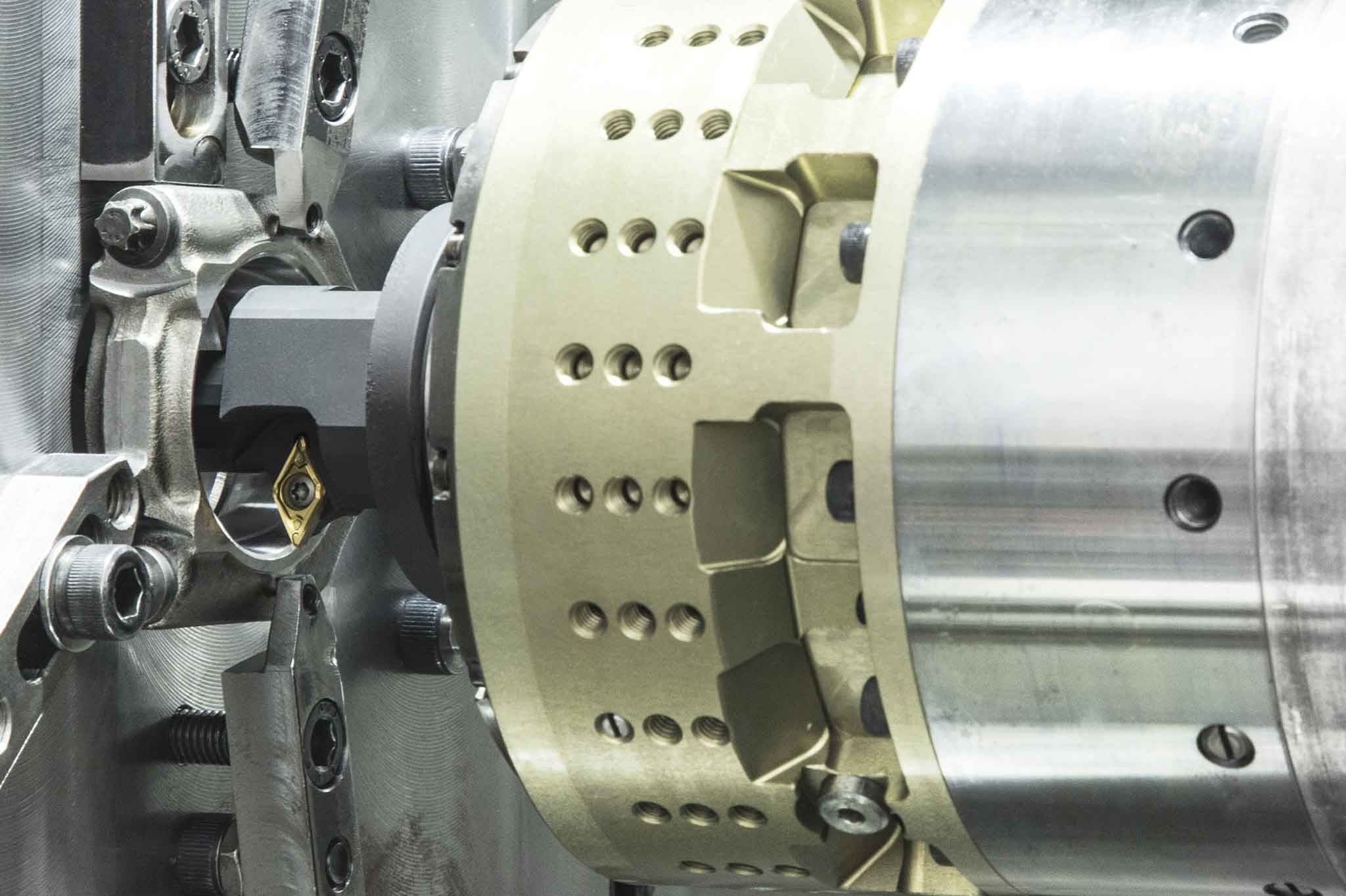

フェーシングヘッド

ラインボーリングバー

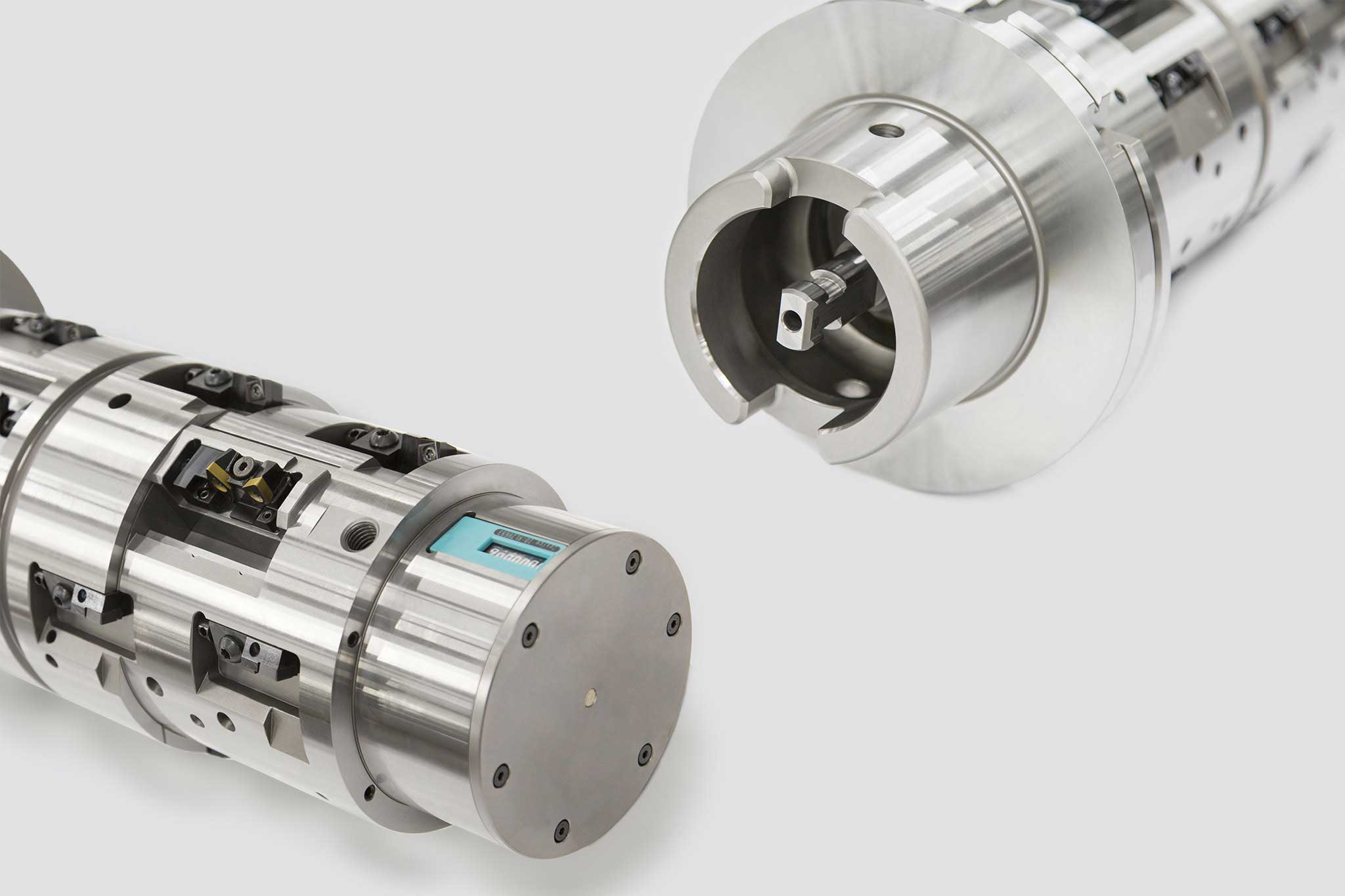

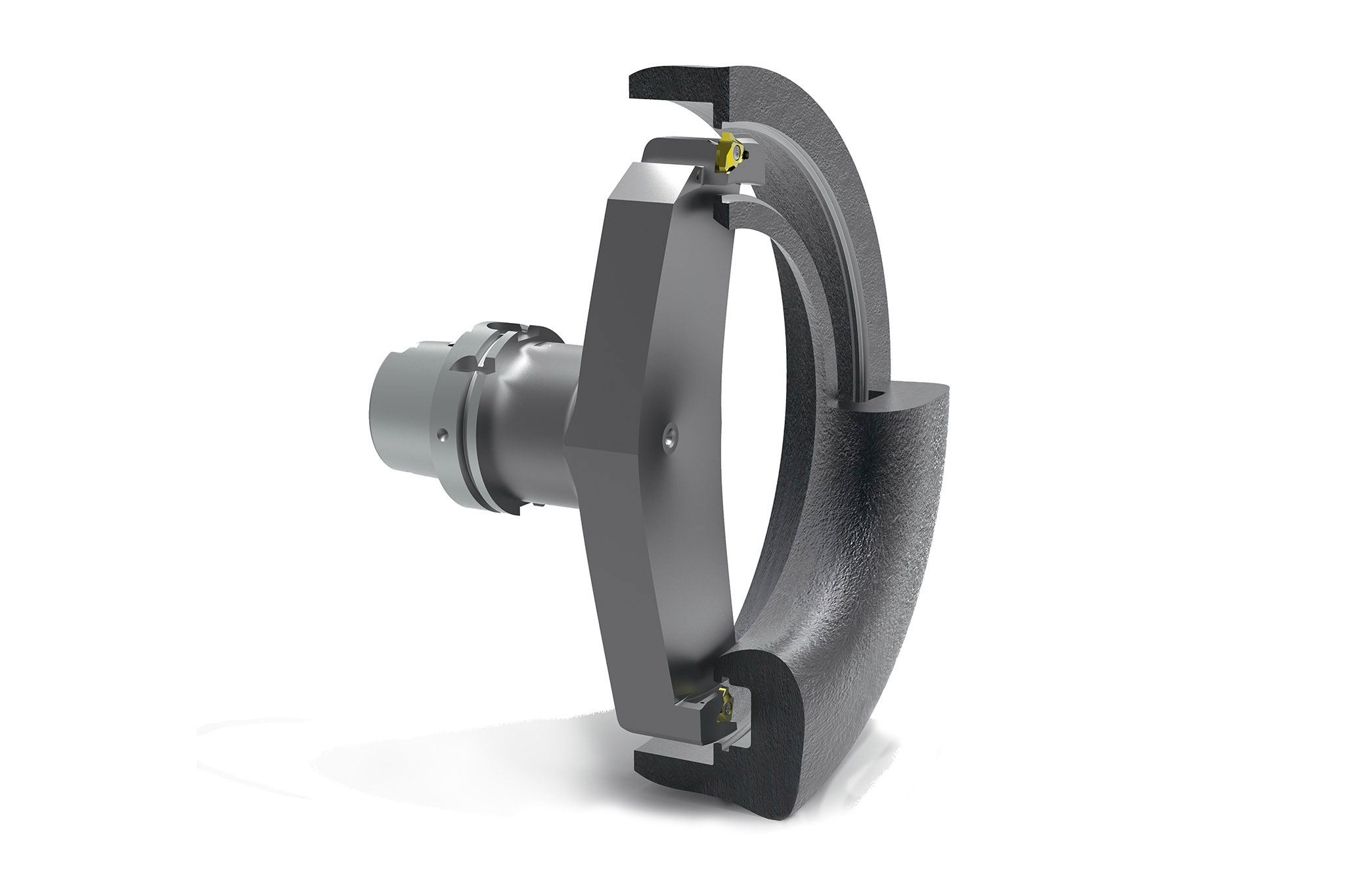

ラインボーリングバーは、ハウジング内 のベアリングジャーナルを特殊加工する ためのツールです。その際、ツールはワー クのクランプ冶具の中の少なくとも1つ のガイドベアリングによりガイドされます。 ツールの複数の刃先により、複数のジャ ーナルの同時加工を行います。オプション のドローバーやプッシュロッドは、ジャー ナルに関連する面削りや刃先の摩耗補 正のための刃先のせり上げを追加で行う ことが可能です。

ラインボーリングバーは、クランク軸およ びカムシャフトの軸受穴の加工に使用さ れます。以上がシリンダーブロックの穴 加工を行う上で最も精度の良い方法と 考えられています。

その他の用途

アクチュエーティングツールのサービス

エンジニアリング - 設計 - 試運転 - メインテナンス

マパールは、アクチュエーティングツールの 分野で製品ポートフォリオ全体に関する包 括的なアドバイスを提供しています。 初回の打ち合わせでは、特殊製品を提供す るために、営業担当者が加工工程に関する 要求を窺います。 特別ソリューションのスペシャリストとして、 標準化されたコンポーネントを使用してお客 様の仕様に合わせた変更も提供します。 また保守期限を計画し、サービス費用を削 減するために、専用のサービス契約を結ぶ ことが可能です。(119ページ参照)。マパールのサービスチームは、決められた メンテナンス間隔でツールを点検します。

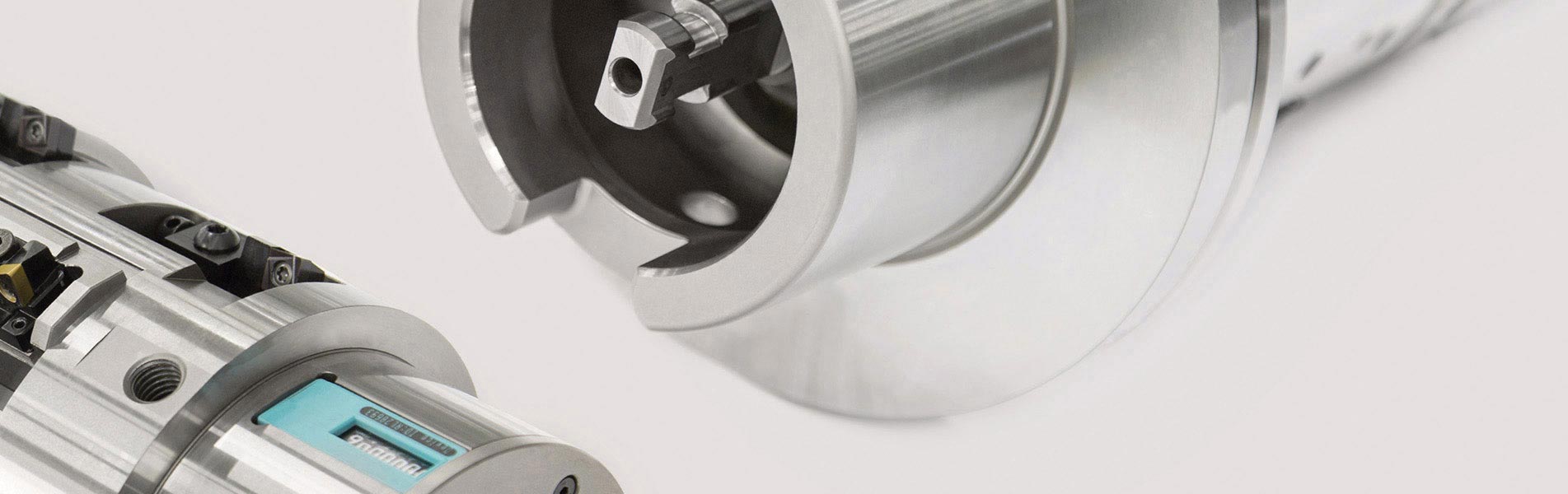

工具内の独立したサービス表示が予防保守と整備を容易にします

ユーザーが回転工具のサービス作業のタイミングと頻度が分からない場合にサポートできるように、マパールは特にシンプルなシステムを開発しました。

サービスチップとLEDを統合し(一部は後付けも可能)、「点滅」によってメンテナンスの必要が差し迫っていることを通知します。その際、稼働時間数が記載されます。

サービスチップとLEDを統合し(一部は後付けも可能)、「点滅」によってメンテナンスの必要が差し迫っていることを通知します。その際、稼働時間数が記載されます。