10.09.2025

75 years of MAPAL

In a history now spanning 75 years, the family business MAPAL has gone from humble beginnings to an international group with a global reputation. From the very beginning, the tool manufacturer’s company history has been characterised by continuity and an innovative spirit that was nourished by Swabian ingenuity and creativity, as well as by the entrepreneurial courage of the owner family Kress. Close contact with customers and a reliable sense for what will matter in future continue to shape the company’s culture to this day.

The foundation of the company in 1950 was quite unusual. Dr Georg Kress held a doctorate in economics and was working as a tax advisor when the opportunity came up to take over one of his clients’ companies, which had got into difficulty. Although he knew nothing about technology, threading tools and dies, he bought “OBA Präzisionswerkzeugbau” from Otto Betzler. He sold his successful tax advisory firm in Aalen and became an entrepreneur.

The new name for the business, MAPAL, stood for “Maschinen- und Präzisionswerkzeugfabrik Aalen” and is testament to the fact that woodworking machines were also manufactured in the company’s early days. As cost-effective and efficient production of the profile milling machines was not possible in the long haul in the cramped, simple premises on Obere Bahnstraße in Aalen, MAPAL quickly moved away from this area of business. The focus switched to tap drills, thread dies and thread rollers, which marked the beginning of the product range as we know it today.

It all started with a reamer

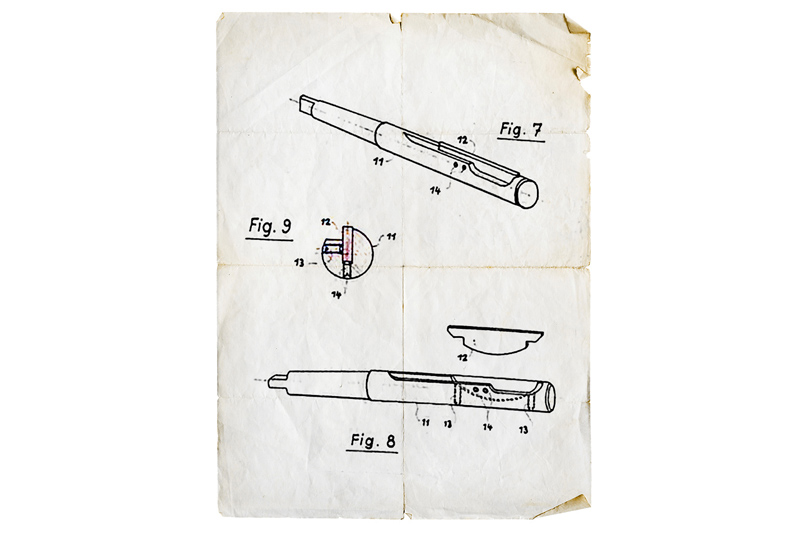

However, Dr Kress drew on research and development to overcome these initial problems. In a painstaking and meticulous process, the reamer was improved. This included inserting two guide pads asymmetrically around the circumference of the reamer body. In 1954, the first single-bladed reamer developed by MAPAL with guide pads made of carbide was patented. Another patent for a reamer with indexable inserts made of carbide followed in 1962. Both innovations laid the foundation for developing the reamers into a highly appealing, high-performance tool in the coming years. The fine machining of bores became MAPAL’s calling card.

When Dr Dieter Kress joined the family business in 1969, the son of the company’s founder was well prepared for his future duties. Unlike his father, he was at home with all things technical. On his very first day working at MAPAL, he designed a new clamping method for indexable inserts. It was patented and in principle still forms the technology for clamping the indexable inserts in MAPAL reamers today.

A forward-thinking product decision

When he became president in 1974, Dr Dieter Kress quickly set about redesigning the product portfolio. The tap drill and thread roller area of the business was given up to focus completely on reamer production. This came at a time when two-thirds of MAPAL’s turnover came from threading tools. But entrepreneurial foresight lay behind this plan. The long-established products offered almost no potential to differentiate the company from mostly bigger competitors who could also manufacture at a lower price. The single-bladed reamer, by contrast, was something very special, with no direct competition. However, the market had to be developed first.

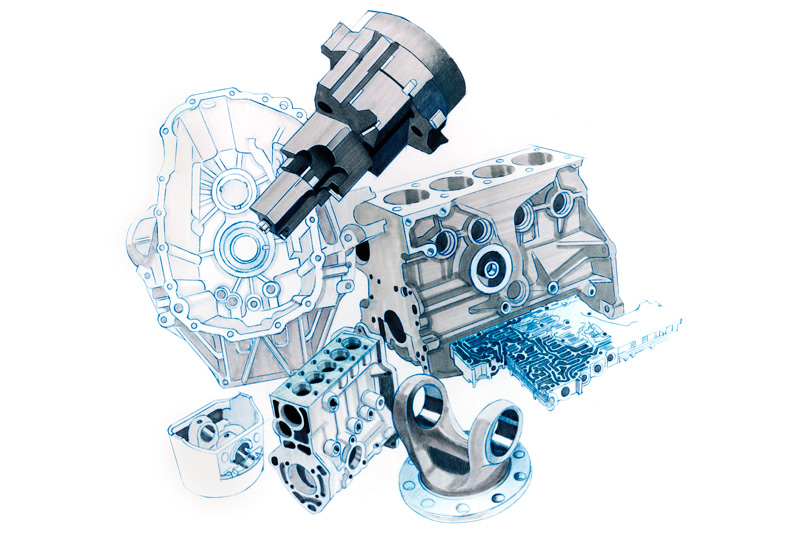

The reamers were gradually developed until they were suitable for industrial large-scale series production. The coating of the indexable inserts played a role, as did the use of PCD for the guide pads. The tools helped MAPAL gain a foothold in the automotive industry first and foremost, where manufacturing technology was moving from rigid transfer lines to flexible machining centres.

Alongside technical improvements, MAPAL rebuilt its sales concept and focused on maximum customer proximity. Independent sales representatives were replaced with in-house technical consultants whose role was to advise customers on the ideal, customised design for their tools and to support them with their use. In the automotive industry the collaboration became so close that the consultants even became involved in developing new engines by introducing potential precision machining options into the design process at an early stage. They didn’t just sell tools – they sold solutions.

Transformation into a global player

To expand its product and service portfolio, which also followed customer requirements, MAPAL acquired specialist companies in Germany. WWS in Pforzheim expanded MAPAL’s offer to include PCD tools with brazed blades for high-speed machining, particularly of aluminium, thus covering a segment that was becoming more and more important to customers. Solid carbide drills and milling tools were added to the range courtesy of Miller in Altenstadt. As drilling from solid is the production step prior to reaming, this made a perfect addition to MAPAL’s portfolio. Weisskopf from Meiningen strengthened the solid carbide segment further.

The purchase of the long-standing Winterlingen-based company August Beck secured MAPAL’s position as a leading manufacturer of reamers. Robert Strom and ISOTOOL added ISO and actuating tools to the portfolio. In 2015, the two companies were rebranded MAPAL ITS, which focuses on complex special tools with actuating mechanisms in Eppingen. Clamping tools from WTE in Ehrenfriedersdorf completed the product range. MAPAL made further strategic investments overseas.

Transformation in full swing

There was also a strategic expansion of customer segments beyond the automotive industry, which had been a guarantee of growth over decades. MAPAL now also focuses on the aerospace, fluid power technology, and die and mould segments. Digital solutions are provided by c-Com since its founding in 2017. The start-up has been merged into the MAPAL Group and primarily assists with tool management services. The company takes all aspects of sustainable management into account with an environmental management system – with many individual measures in production and administration at all sites making their contribution.

Dr Jochen Kress initiated the transformation of MAPAL into a process-driven, global organisation. Structures and processes are being adapted to the size the company has reached; decision-making processes are being streamlined and accelerated. The reorganisation on management level at headquarters in Aalen is based on core processes and areas of focus. The structural, organisational and cultural changes that Dr Jochen Kress initiated will shape the company in the long term and endure long beyond the anniversary year 2025.

As it celebrates its 75th anniversary, the MAPAL Group is resolutely focussed on the future. With investments in new technologies, digitalisation and in the targeted development of capabilities, the company is strengthening its position in key sectors and accelerating its efforts to engage with the market and its customers. This is reflected, for instance, in the activities in the dynamically developing Aerospace segment: MAPAL has pooled its expertise in the field of aircraft final assembly in the Global Organisation for Assembly (GOA) department, founded in 2024 – a decisive step to serve global customers faster and in a more targeted manner. The integration of the subsidiary c-Com and acquisition of the Italian X-Pro S.r.l., a specialist in turnkey projects and clamping fixtures, also highlight the company’s commitment to actively shaping technological developments and fully meeting customer requirements.

Contact

Mathias Ostertag Public Relations mathias.ostertag@mapal.com Phone: +49 7361 585 3566