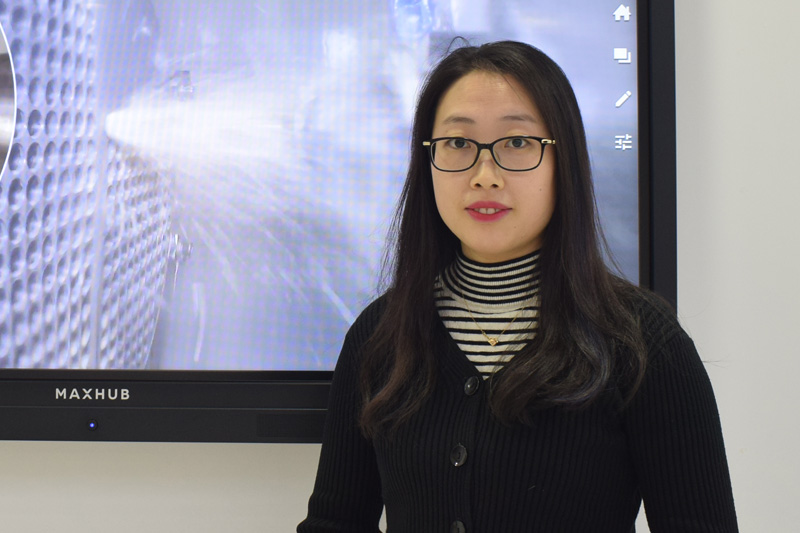

Les personnalités de MAPAL: Adrien Lacour

En tanto jefe de equipo del área de torneado y fresado de MAPAL France S.A.S., Adrien Lacour da por hecho que su jornada laboral va a ser muy variada.

Así, pasa de la sala de máquinas al escritorio igual que un jugador de equipo que asume múltiples posiciones. Adrien Lacour ocupa un importante puesto de intermediario en el área de torneado y fresado entre la producción y la dirección en la sede francesa de Le Chambon-Feugerolles.

«Soy el responsable de pedir materiales y herramientas, preparo las piezas terminadas para llevarlas al tratamiento térmico y organizo los turnos del equipo. Además, colaboro en la fabricación. Gestiono mi sector, en la medida de lo posible, de forma independiente, por lo que tengo que conocer todas las máquinas y comprender sus correspondientes tolerancias», así resume Adrien Lacour su ámbito de actividad en MAPAL France S.A.S. La sede de Chambon-Feugerolles, cerca del municipio de Saint-Étienne, se centra en la producción de escariadores multicuchilla, taladros y fresas completos en metal duro y herramientas de PCD.

MAPAL es la primera estación profesional de Adrien, nativo también de la región de Auvernia-Ródano-Alpes. Tras superar los exámenes del bachillerato técnico, realizó un grado en Ciencias durante el cual se especializó en innovación tecnológica y en diseño ecológico. Completó esta formación con una titulación superior de dos años centrada en la industrialización de procedimientos mecánicos. Posteriormente, en 2014, comenzó su formación como tornero en MAPAL y, al terminar, se le ofreció un contrato fijo. «Por aquel entonces estaba buscando una empresa que me permitiera realizar dos años de estudios superiores para obtener un diploma de técnico superior y que estuviera orientada a la práctica. Me decidí por MAPAL porque ofrecía un entorno de trabajo idóneo, con un taller organizado y limpio. También estaba la posibilidad de descubrir el mundo del mecanizado, que por aquel entonces era desconocido para mí», recuerda Adrien, que acaba de recibir un ascenso a jefe de equipo del área de torneado y fresado.

Responsable de la productividad

Formado en todas las máquinas

Su ascenso supuso un motivo de especial alegría, ya que se le otorgaba una gran confianza y se le asignaban cometidos de gran responsabilidad con un amplio margen de maniobra. En su nuevo puesto, deberá seguir adquiriendo cualificaciones y desarrollando sus competencias. Ha optado en primer lugar por reforzar sus habilidades en conjunto con una formación relativa a varias máquinas. «La empresa me ofrece cursos sobre distintas máquinas para ampliar mis conocimientos. Así, podré usar todo el parque de máquinas del sector del mecanizado y utilizar el software para la construcción y la fabricación asistidas por ordenador», explica Adrien, quien no duda en echar una mano de vez en cuando como tornero CNC y fresador cuando se necesita ayuda.