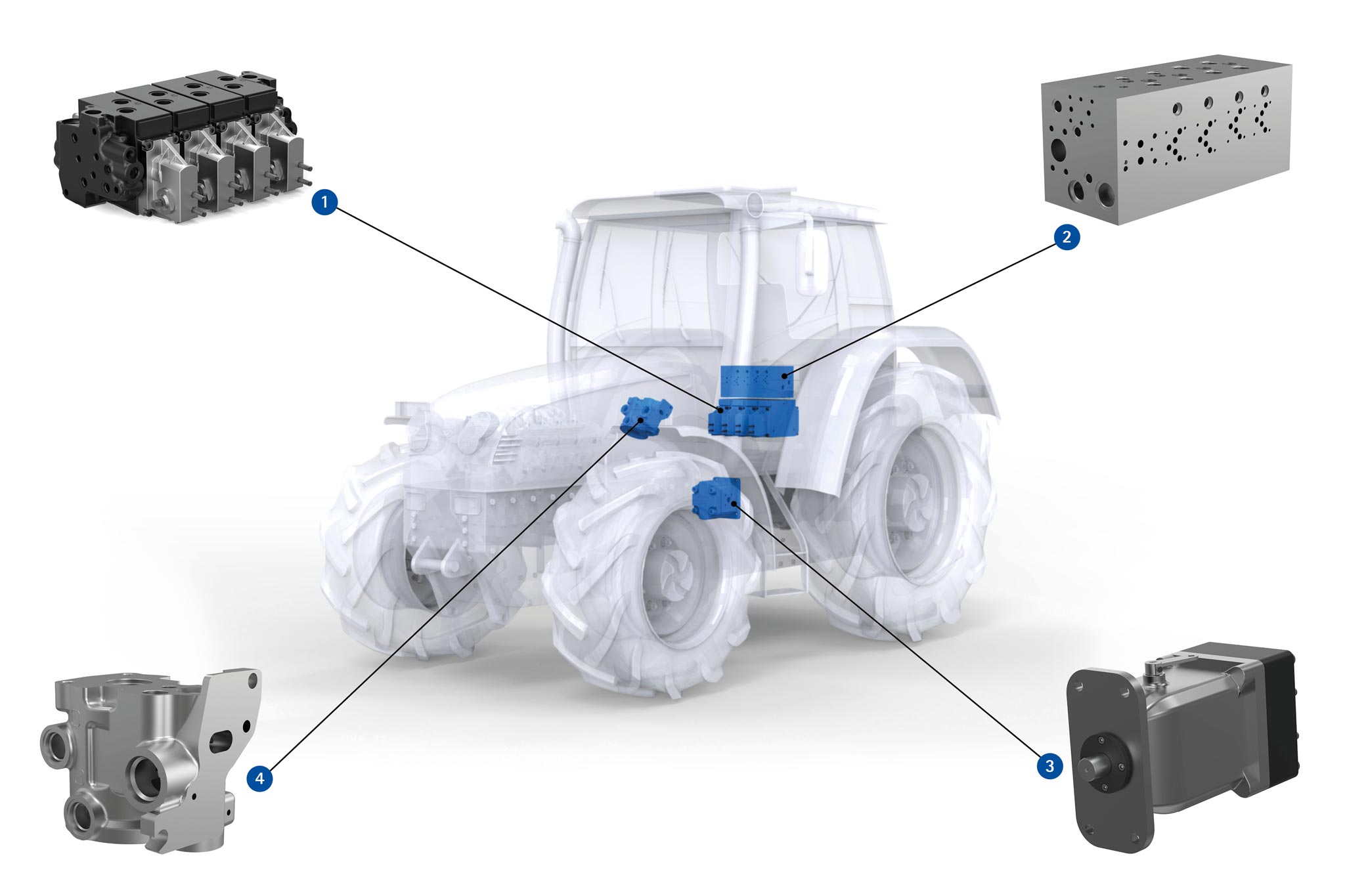

Hydraulics

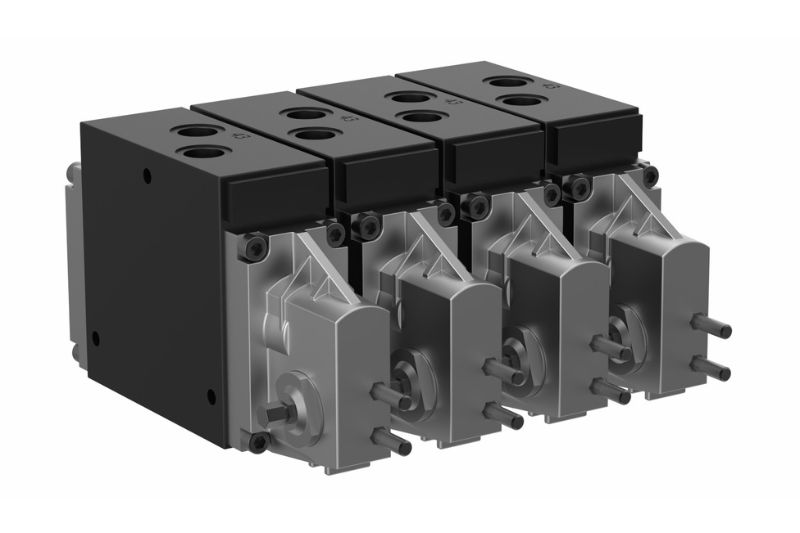

- (1) Hydraulic valve housing

-

Machining solutions for hydraulic valve housing

Everything depends on the main bore. Manufacturing valve housings

is the supreme discipline in the world of fluid power. For years, MAPAL’s

expertise has been in demand for the spool bore. The gap dimension

with the spool depends on the accuracy of this bore, so that the

hydraulic oil can only flow in the required direction without

leaking. This is very narrowly defined in modern hydraulic

valves. The roundness, cylindrical form, straightness

and surface finish of this bore are therefore crucial.Basic procedure – analysis of the machining process

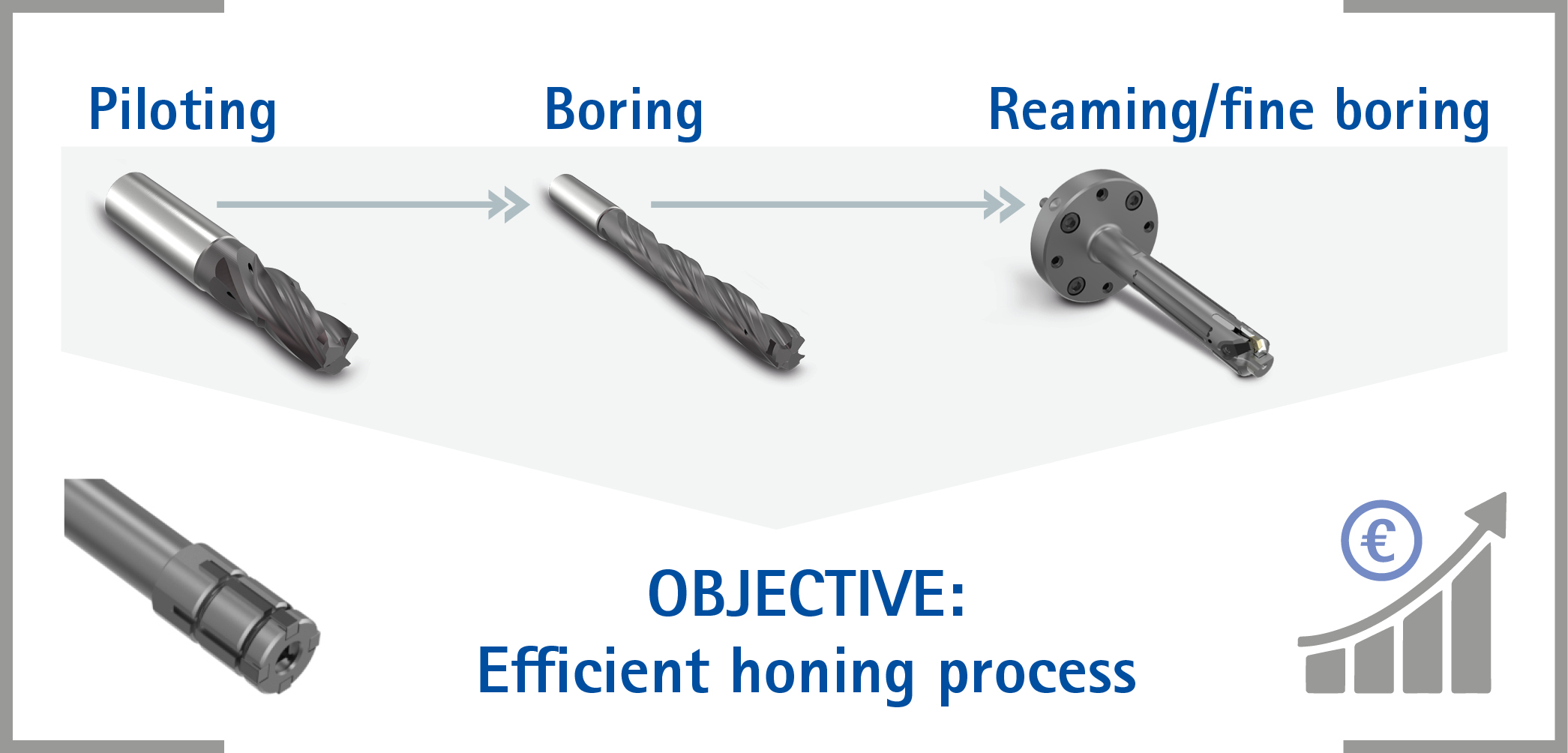

As technology partner, MAPAL supports customers with regard to complete process design. The experts pay particular attention to the cost drivers here, which can often be found in the function-relevant bores. Based on the respective honing procedure, the part requirements and lot sizes, MAPAL designs the perfect machining strategy in dialogue with the customers.One objective unites all activities: designing the most economic process, starting with piloting, boring and semi-finish machining up to the efficient honing process. - (2) Control block

-

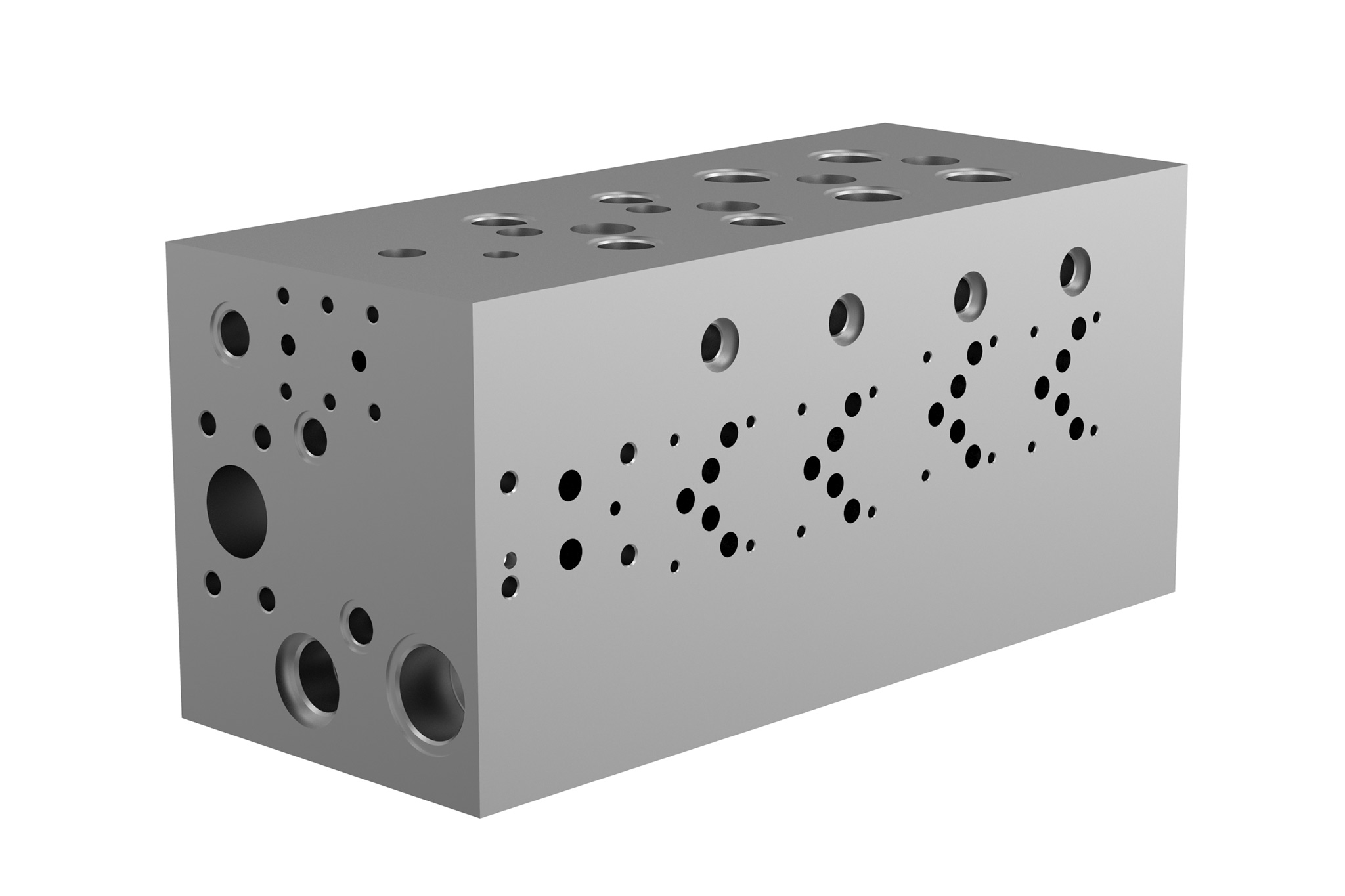

Control block

The hydraulic control block connects diverse valves and control components. These are installed in or mounted on the control block, which acts as a control and distributing system in hydraulic circuits.Basic procedure – analysis of the machining process

As technology partner, MAPAL supports customers with regard to complete process design. The experts pay particular attention to the cost drivers here, which can often be found in the function-relevant bores. Based on the respective honing procedure, the part requirements and lot sizes, MAPAL designs the perfect machining strategy in dialogue with the customers.

One objective unites all activities: designing the most economic process, starting with piloting, boring and semi-finish machining up to the efficient honing process.

- (3) Axial piston pump

-

Axial piston pump

Axial piston pumps and motors together are referred to as axial piston machines. An axial piston pump transforms mechanical energy into hydraulic energy and an axial piston motor transforms hydraulic energy into mechanical energy.

Axial piston machines are characterised by a high degree of stability and good interior sealing, which allows high pressures.Basic procedure – analysis of the machining process

As technology partner, MAPAL supports customers with regard to complete process design. The experts pay particular attention to the cost drivers here, which can often be found in the function-relevant bores. Based on the respective honing procedure, the part requirements and lot sizes, MAPAL designs the perfect machining strategy in dialogue with the customers.

One objective unites all activities: designing the most economic process, starting with piloting, boring and semi-finish machining up to the efficient honing process.

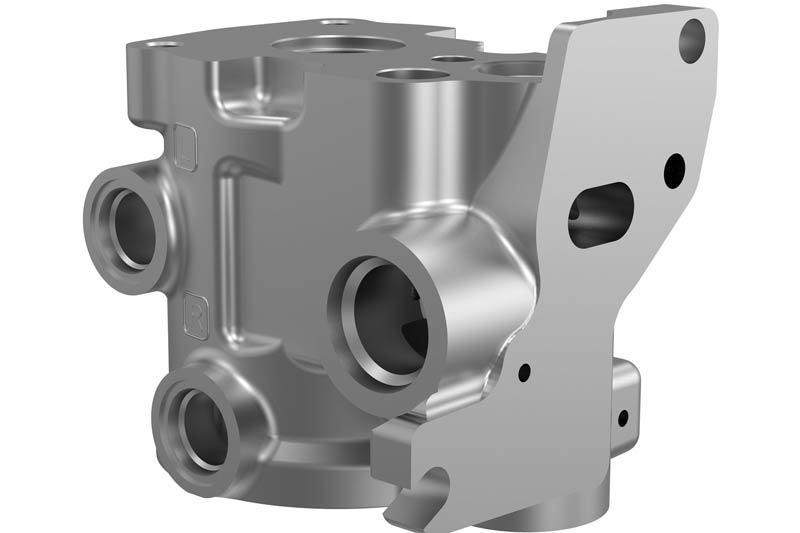

- (4) Orbitrol

-

Orbitrol

The orbitrol is the main control element of hydrostatic steering systems. Depending on the movements of the steering wheel, the volume flow produced by a hydraulic pump is directed to the working area of the hydraulic cylinder, which operates the Ackermann steering. A priority valve is used here to ensure steering system durability.Basic procedure – analysis of the machining process

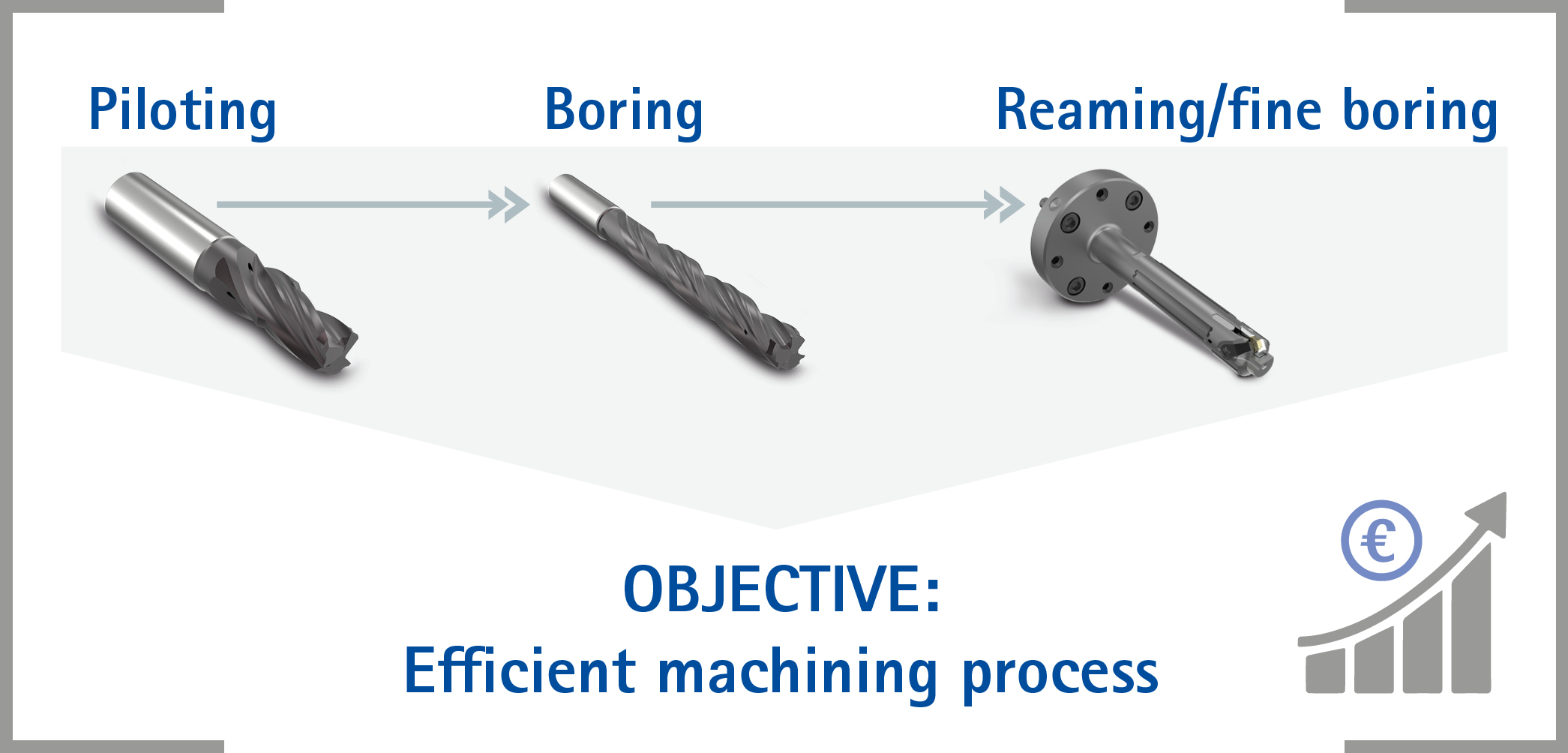

As technology partner, MAPAL supports customers with regard to complete process design. The experts pay particular attention to the cost drivers here, which can often be found in the function-relevant bores. Based on the respective honing procedure, the part requirements and lot sizes, MAPAL designs the perfect machining strategy in dialogue with the customers.One objective unites all activities: designing the most economic process, starting with piloting, boring and semi-finish machining up to the efficient honing process.