Hydraulic control block

Hydraulic control block 9SMn28k / EN-AW6082

Initial situation at the customer

- Individual orders, smaller and medium quantities

- High degree of part and workpiece material variance

- Low lead time

- High quality requirements for surfaces and minimal burr formation

Special features of this solution

- Different workpiece materials can be machined with a single tool body → Insert solution allows maximum flexibility for small lot sizes

- Tool breakage avoided when producing overlapping oil channel bores

- Secure chip control when machining long-chipping material

- Efficient multi-stage tool → Reliable production of form and position tolerances

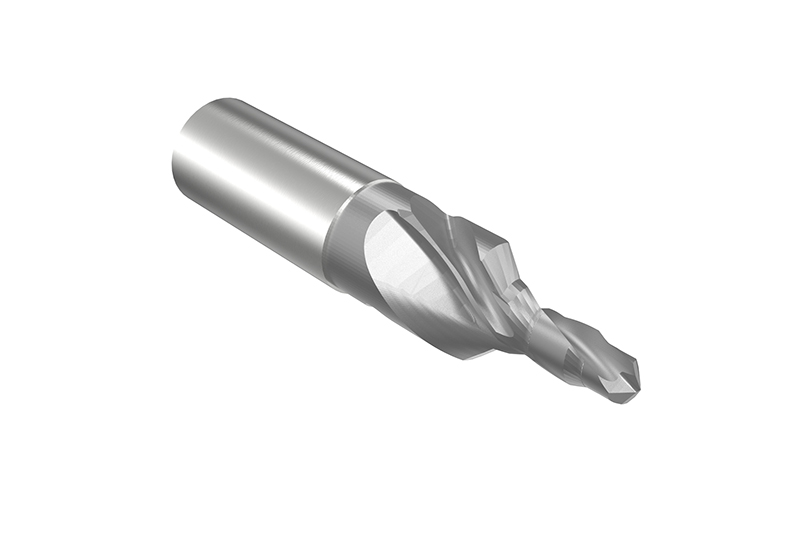

Valve bore

Oil bore

![TOOL LIFE OIL CHANNEL DRILLING [DRILLING HOLES]](/medias/sys_master/root/hf3/h2f/9175133159454/Grafiken__EN2/Grafiken-EN2.jpg)

Advantages

- Ideal workflow ensures highest level of productivity and minimal lead time

- Combination tools replace other tools for high part and workpiece material variances and limited tool stations

- Tool solution with multiple usage scenarios for various parts in valve and connection bores

- Large standard portfolio ensures simple and quick machining of small series and prototypes

![MACHINING TIME PER VALVE BORE [SEC.]](/medias/sys_master/root/h04/h33/9175133224990/Grafiken__EN3/Grafiken-EN3.jpg)