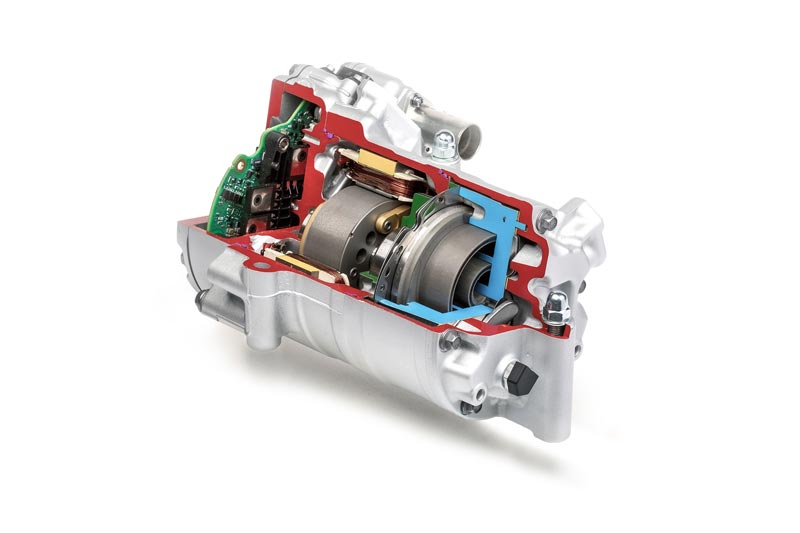

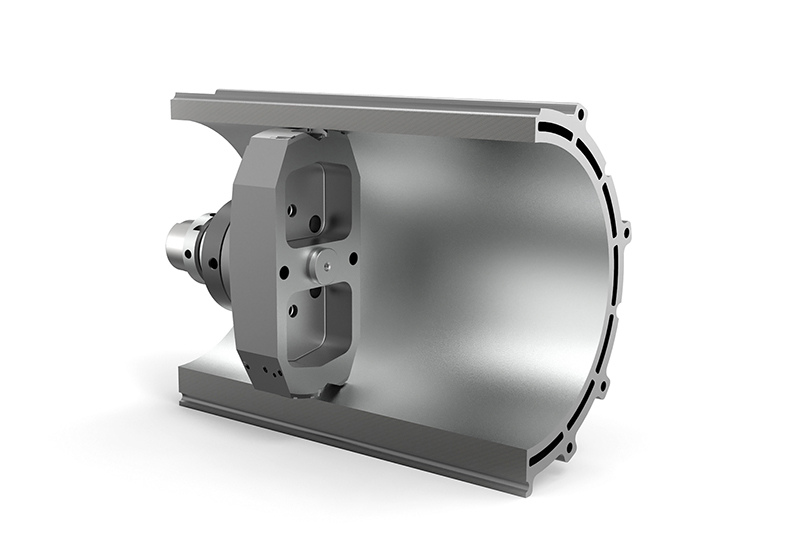

Machining solutions for electric motor housings

Prototype, pre-series and small series construction

Simple, flexible and cost-effective tool solutions

- Machining on existing machines

- Standard tools or simple custom tools

- Compromise solutions → small machine – big tool

- Cycle time is not the focus

- High flexibility is what is wanted

- Universal application

- Contour independent

1. Pre-machining

Flexible for different diameters

Helix milling cutter with ISO indexable inserts

- Coated ISO indexable inserts made of carbide or PCD-tipped indexable inserts

- Reduced cutting forces

- Standard product

- HSK extension for different machining depths

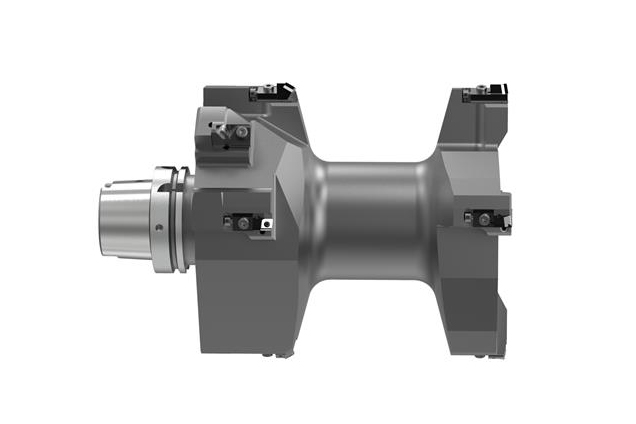

2. Semi-finish machining

Contour-forming to approximately the final contour

Boring tool with ISO indexable inserts

- ø 210 mm

- Tool shape adapted to magazine changer

- Coated ISO indexable inserts made of carbide or PCD-tipped indexable inserts

- Weight: max. 3.5 kg

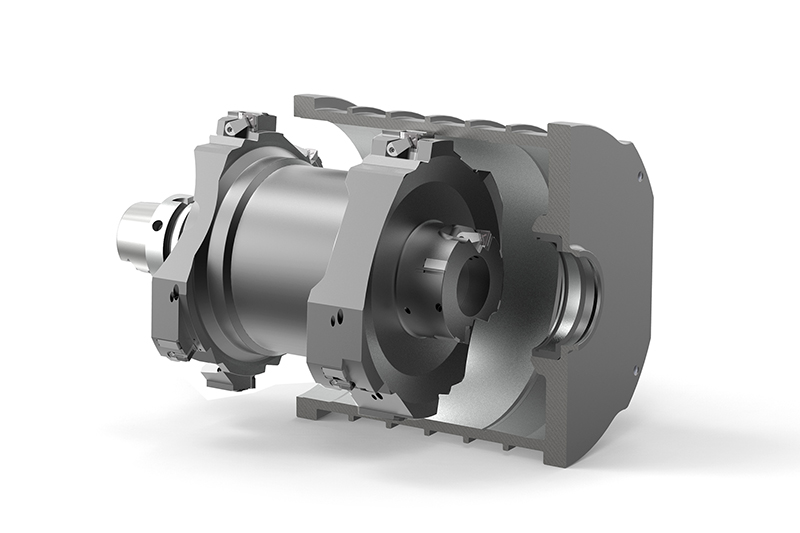

3. Finish machining

With simple custom tools

Fine boring tool with guide pads

- ø 210 mm

- PCD-tipped indexable inserts

- Finely adjustable

- Guide pads made of PCD

- Tool shape adapted to magazine changer

- Weight: max. 5.5 kg

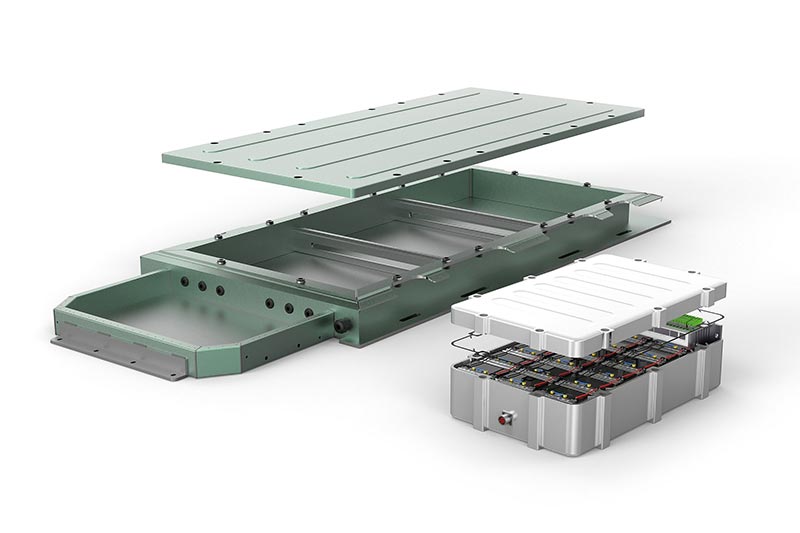

Pre- and finish machining

Alternative with standard tools

Boring heads with bridge module and ISO cartridges / fine boring cartridge

Modul bore - High flexibility during boring and fine boring

- Pre- and finish machining system

- Modular construction

- Standard programme from ø 87 mm – 1000 mm

- Fine boring cartridge adjustable in the μm range

- Easy handling

Your direct contact

Contact person

Michael Kucher Component Manager E-Mobility michael.kucher@mapal.com +49 7361 585 3557