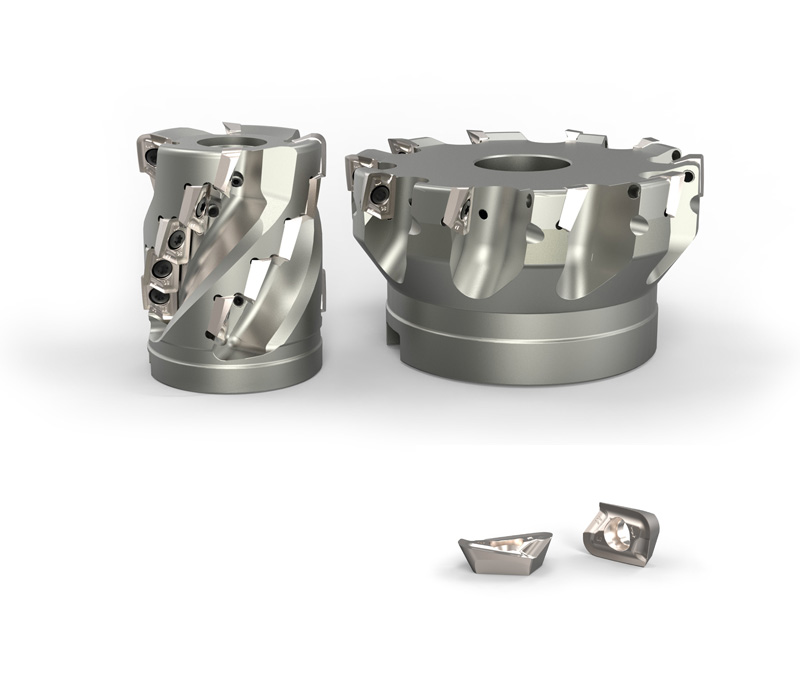

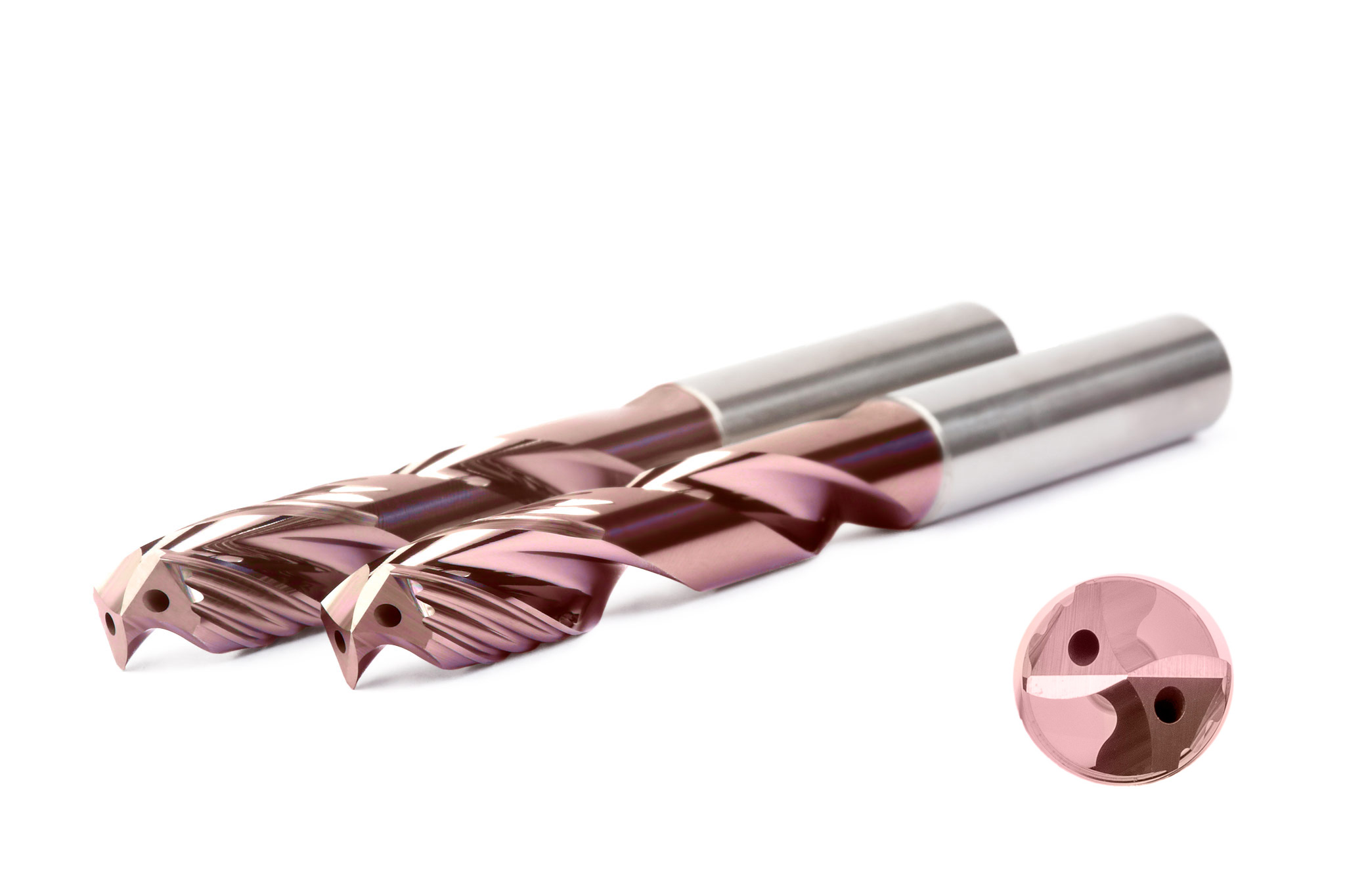

Nuevos productos para el mecanizado de titanio

La reducida conductividad térmica del titanio, junto con su elevada resistencia a la tracción, hace que las herramientas estén sometidas a un gran esfuerzo térmico y mecánico. El nuevo programa de herramientas para titanio de MAPAL se caracteriza por su sofisticada disipación térmica y por sus recubrimientos resistentes al calor. De este modo, se pueden obtener valores de corte comparativamente elevados de forma segura. Al contrario de lo que ocurre con las soluciones habituales del mercado, las herramientas MAPAL cuentan con una vida útil entre un 25 % y un 35 % mayor.