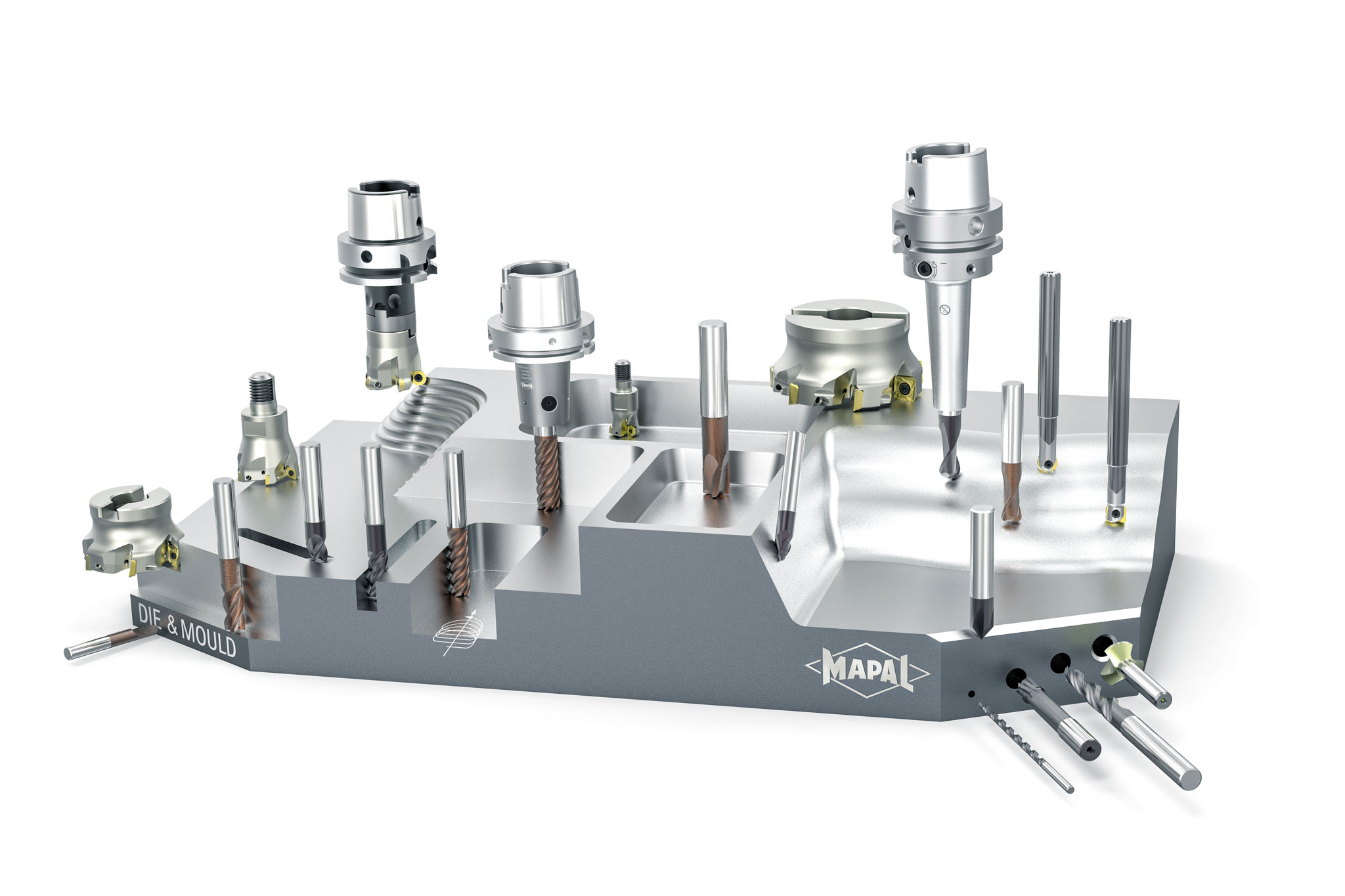

Partenaire technologique et fournisseur complet du secteur de la fabrication des moules et des matrices

Outre des outils et des mandrins, MAPAL propose des processus complets et des solutions de programmation CN.

Les entreprises de fabrication d'outils et de moules attendent un haut niveau de compétence de la part des fabricants d'outils. En effet, la durée de vie des moules à fabriquer et la précision des pièces moulées sont extrêmement importantes pour la compétitivité dans la fabrication des produits finis. L'on exige des outils qu'ils soient hautement précis, particulièrement durables et, le plus important, sûrs.

正是在应对这些苛刻的挑战的过程中,使MAPAL公司在众多领域取得了重要的成功,尤其是在汽车工业、机床制造或者航空工业等领域成果卓著。因此,为模具制造的整个切削加工工艺提供高效和经济的解决方案是合乎逻辑的。

模具制造的规划已经构成了MAPAL集团刀具供货系列的一个横向阵列——从使用固定或是可更换的刀片的铣削,到钻孔,再到锪孔和铰孔。。该产品组合包括大约 6,500 件产品,根据所使用的材料(例如钢、硬化钢、铸铁、铝和铜以及石墨)量身定制。诸如具有高进给几何形状的铣刀等许多亮点皆属于该产品组合。

Tanto a versão em metal duro inteiriço da série OptiMill quanto as geometrias com arestas de corte intercambiáveis permitem usinagem com altas taxas de remoção de material e podem ser usadas de forma flexível. Outros destaques incluem as fresas barril OptiMill-3D-CS com seu amplo raio efetivo ou a MEGA-Drill-Reamer, que combina duas operações em uma, e é usado principalmente para pinos guia e furos de ejeção.

Devido à alta especialização no segmento de mercado do setor de moldes e matrizes e a demanda significativamente crescente por soluções de tecnologia e gerenciamento, o foco não está mais nas soluções de ferramentas apenas ao selecionar o parceiro de usinagem certo. Estratégias de usinagem, máquinas-ferramenta, sistemas de fixação de peças, sistemas CAD-CAM e soluções para gerenciamento de ferramentas fazem parte do processo de usinagem e são decisivas para uma fabricação eficiente e econômica.