涡旋压缩机

涡旋螺杆由欧标 EN AW-4032(AlSi12.5)/铝合金材料以及欧标EN-GJS-400-15/铸铁制造

客户的初始情况

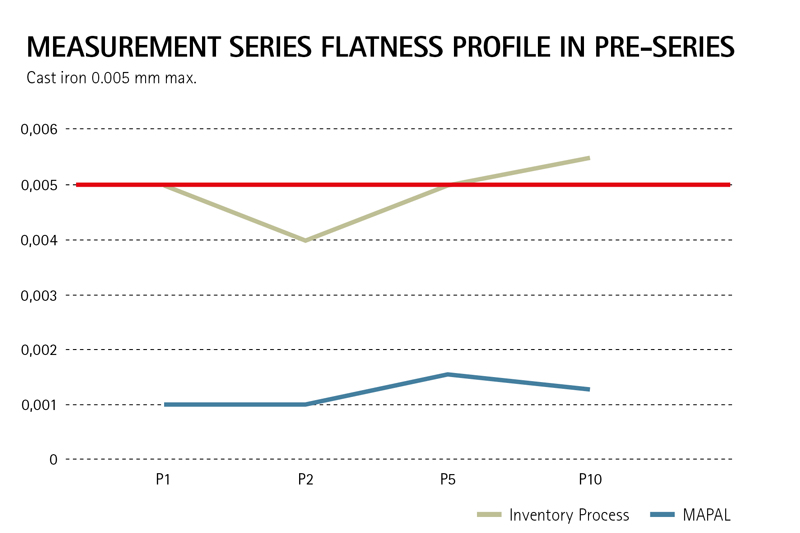

- 在进行薄壁结构组件的加工中,由于工件质量不稳定,曾频繁引发终端客户的投诉

- 铸铁涡旋结构件的初始批量状态

Special features of this solution

- Frequent customer complaints about fluctuations in component quality for machined thin-walled parts

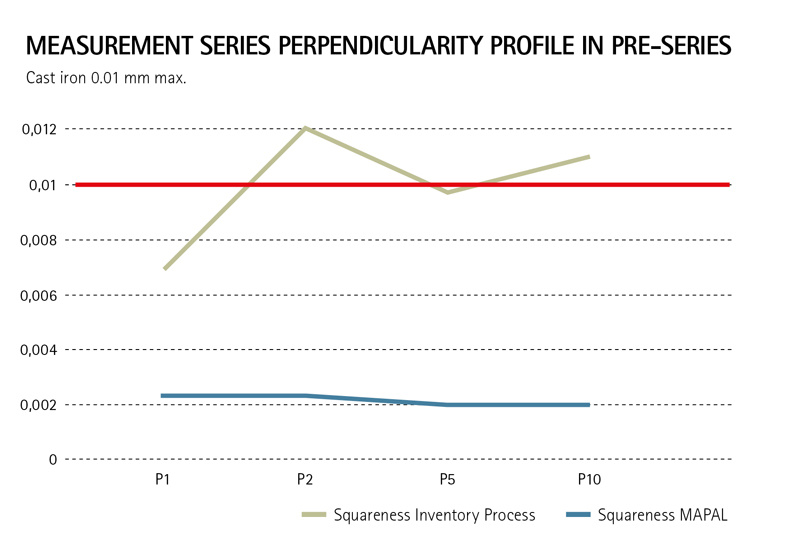

- Pilot run status of scroll parts made of cast iron

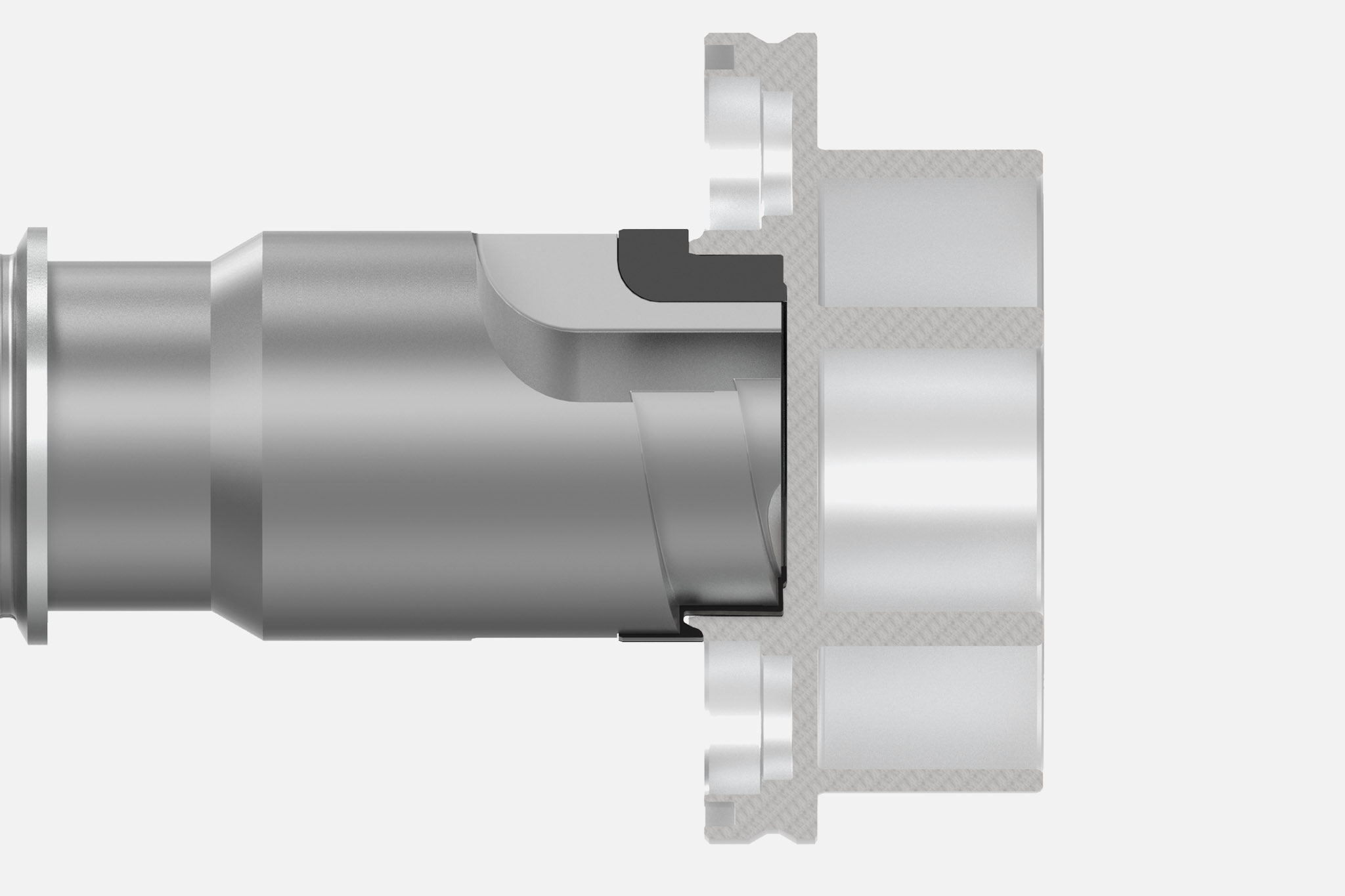

Aluminium scroll

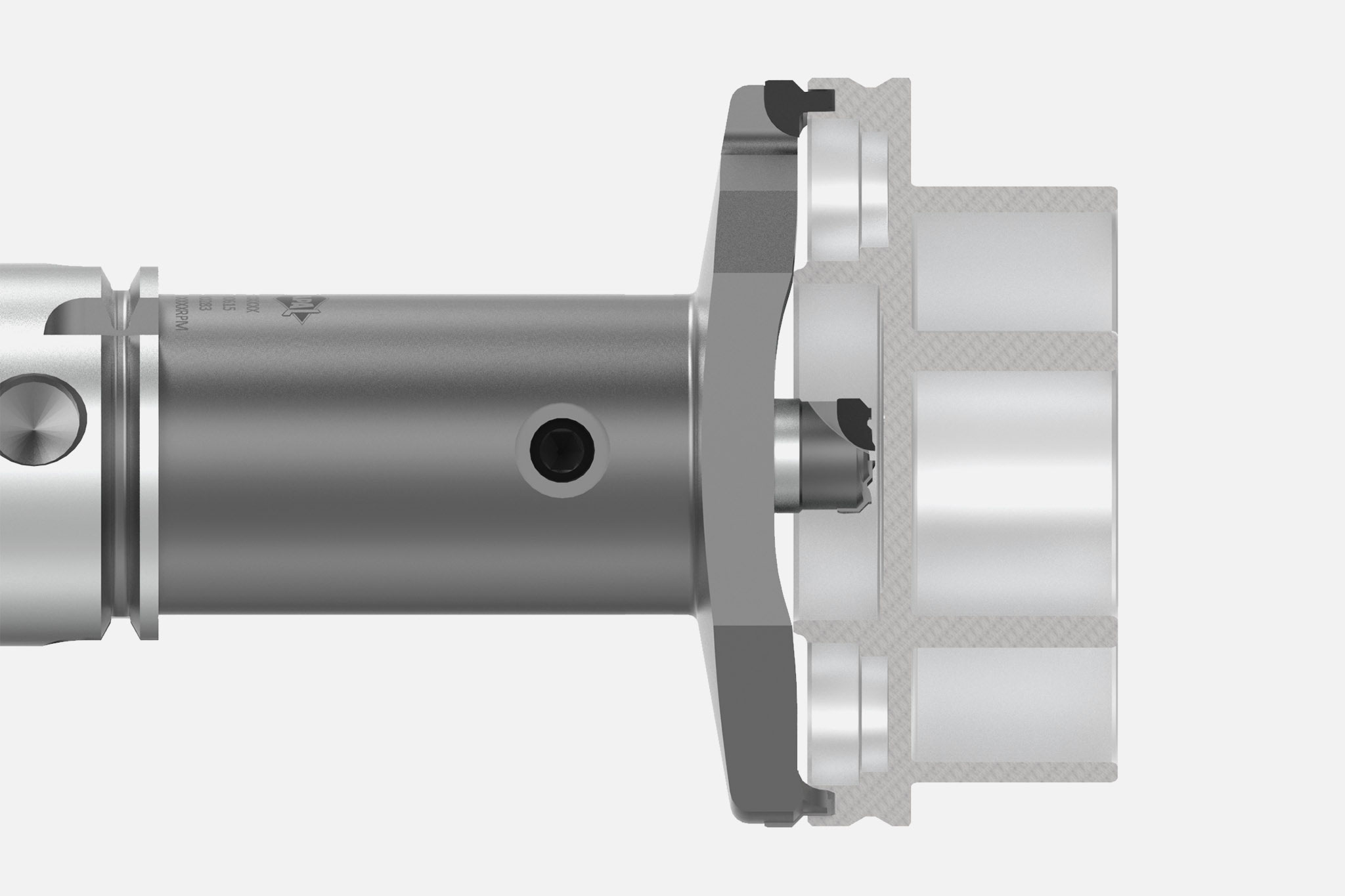

Cast scroll

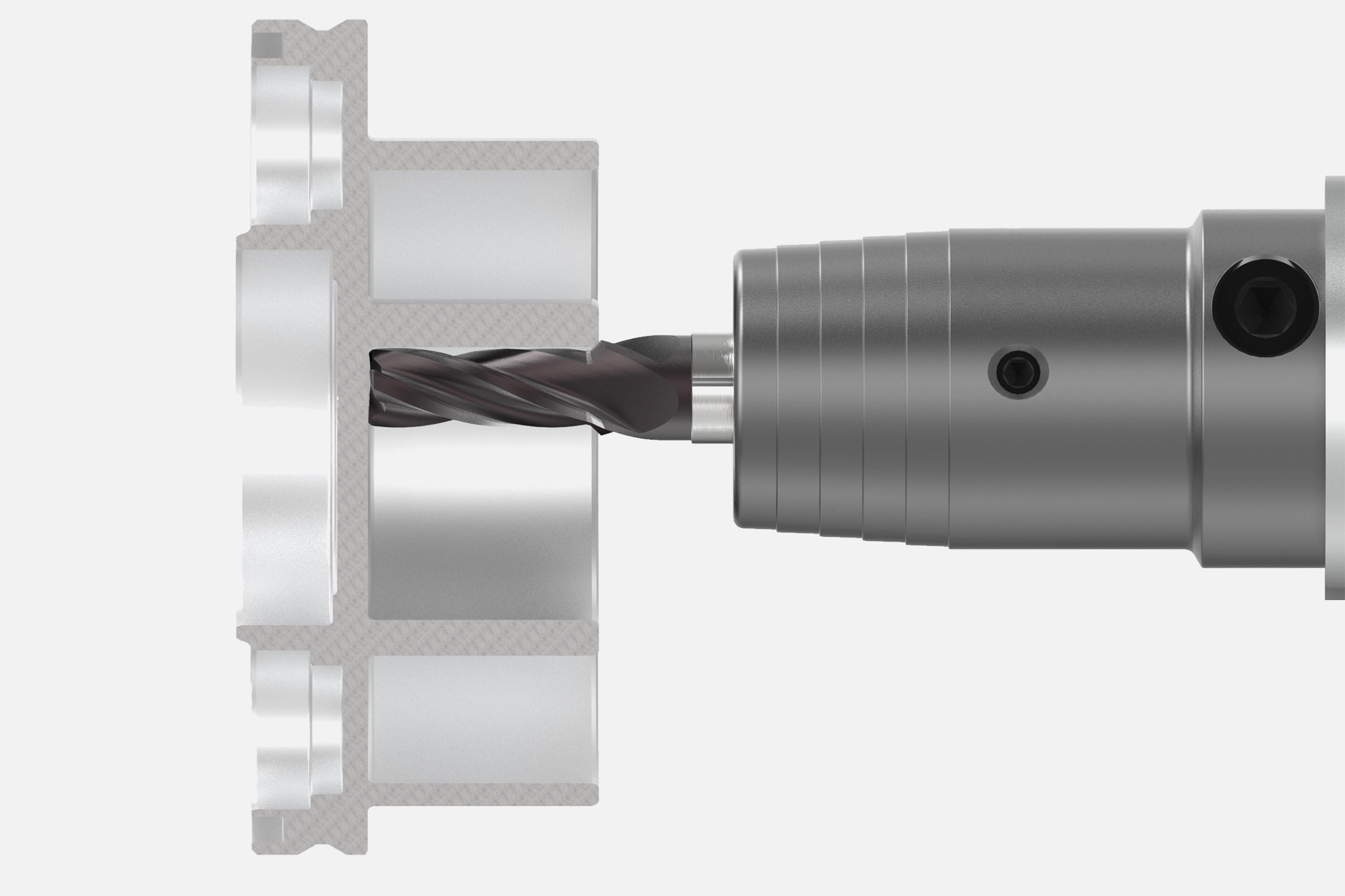

Processing steps on the scroll compressor

Advantages

- Thanks to consistent component quality, customer complaints are avoided and costs are reduced considerably

- Clear competitive advantage thanks to the cooperation with MAPAL and its years of experience and specialisation in motor vehicles

- Intense supervision of series production enables reliable end-to-end machining of aluminium and cast iron