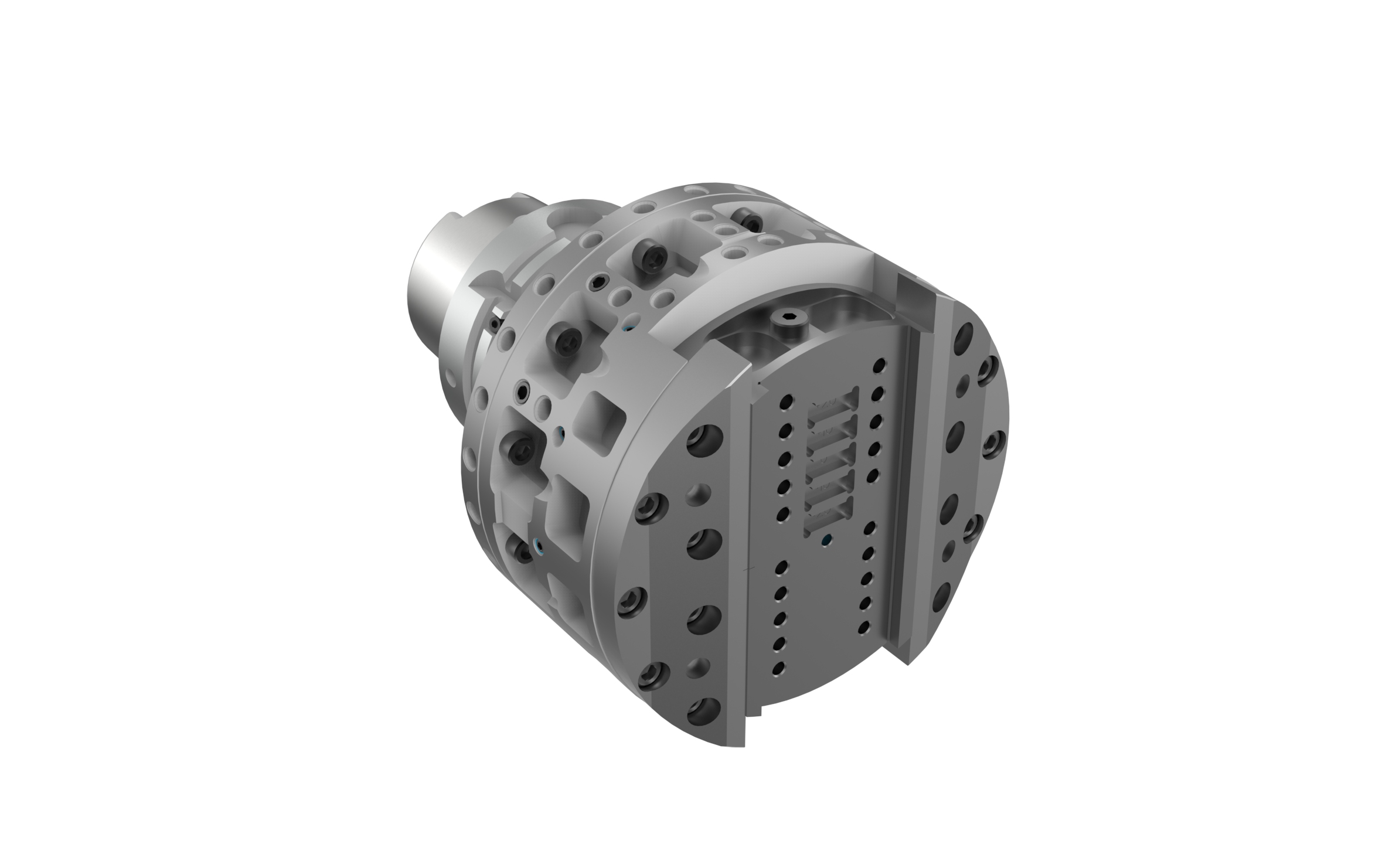

执行器-外壳体

采用执行技术获得各种应用解决方案

AlSi10材料制成的执行器壳体

客户的初始情况

- 仅通过一个刀具系统,可完全满足复杂轮廓加工的要求:端面加工、倒角加工、直径加工以及锥度加工1:50 (1,1146°)

- 对形状和位置公差以及IT8-公差的要求非常高

本解决方案的特点

- 可以最佳的同轴度完成内、外部的各加工流程,并确保工艺的可靠安全

- 实现自动换刀

- 通过姐妹刀具的设置,使得刀具设置不影响主加工时间

- 通过柔性化的工艺流程,可以在对刀仪上进行预设置

- 可在同一主轴上应用标准刀具(如:钻头或者铣刀)

- 可转位刀片技术使得切削刃材料成本大大降低

刀具亮点

- 带U-轴HSK-A100(旋转轴)

- 仅一个套装刀具完成内、外部加工

- 平面行程 56mm

- 加工直径范围112 mm

- 使用套装刀具通过五个步骤移动,以达到最大的直径范围

- 通过内部冷却通道向切削刃直接供给冷却液,实现了最佳的冷却液输送

.pptx - PowerPoint/2023-11-29-14-00-36-Aussteuern-Kundenpr-sentation-EN-1-.pptx-PowerPoint.jpg)

优点

- 仅通过一个刀具系统,即可实现复杂的轮廓加工并满足所要求的精度

- 针对所有的系列型号方案,仅需两种刀具类型,因此确保了在批量加工过程中实现低切削材料成本的优势

- 对于各种轮廓以及锥度形状1:50 (1,146°),可以进行自由编程和修正,因此在较高偏差状态下,也可实现最大的工艺可靠性

- 联手MAPAL的技术合作,即可实现对所有加工步骤的最佳化配置集成