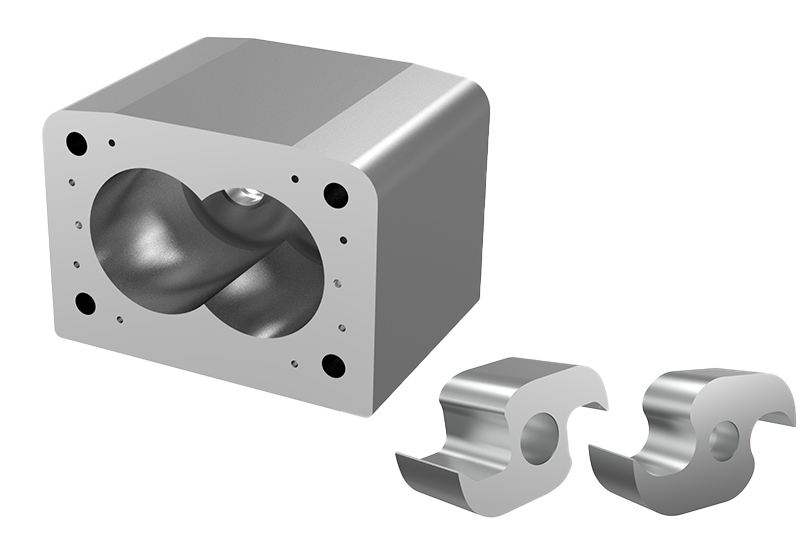

爪式真空泵

泵外壳体由欧标 EN-GJL-250 铸铁制造 |

爪由 1.4021(X20Cr13)不锈钢制造

爪由 1.4021(X20Cr13)不锈钢制造

客户的初始情况

- 在以往的批量加工工艺中,由于采用非柔性化刀具解决方案而造成很高的刀具成本

- 在该爪的生产过程中,由于机械切削部分占比巨大,引发了大幅的成本压力

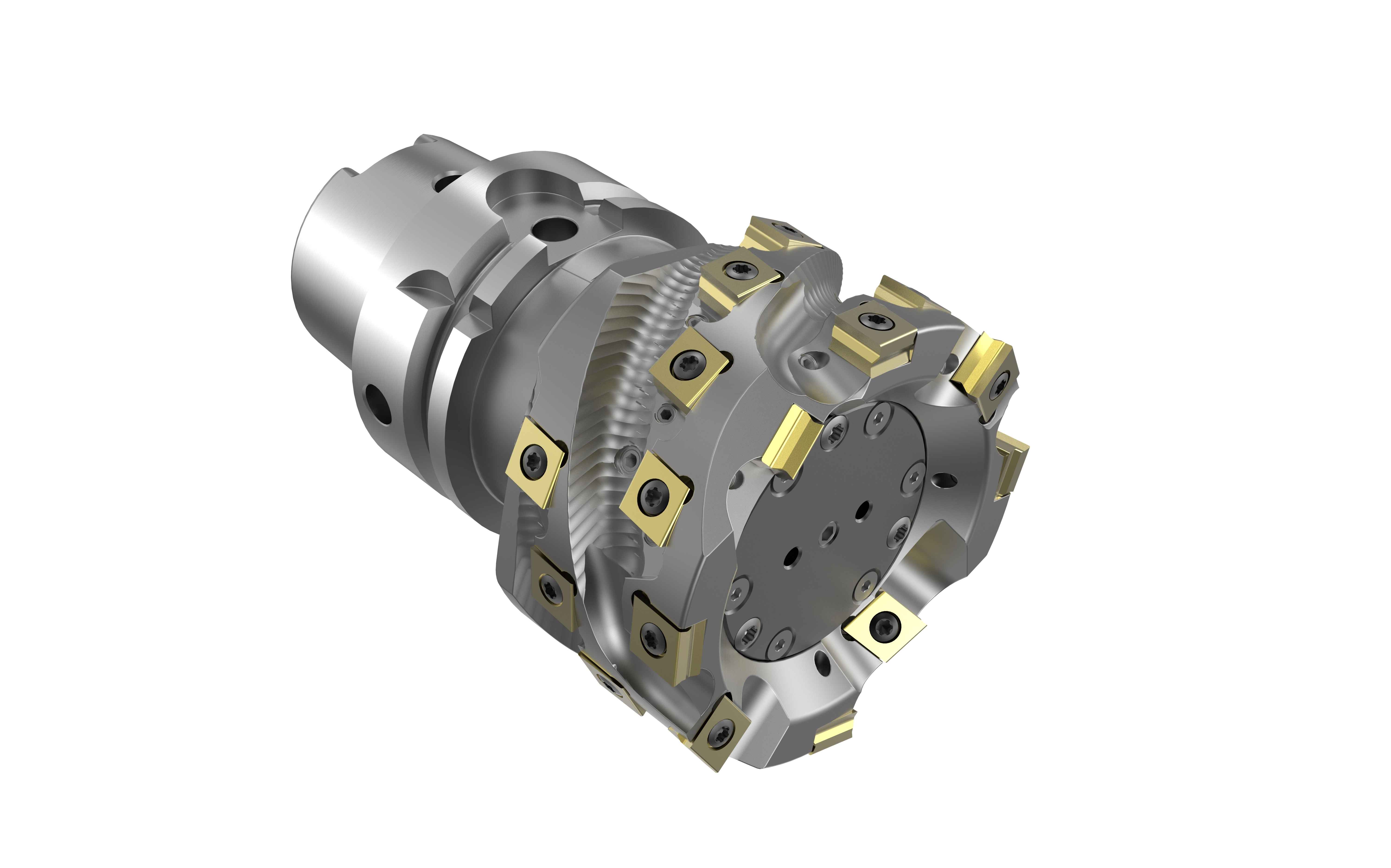

解决方案的特性

- 通过采用可转位刀片的解决方案,也大幅缩减了切削材料的成本

- 通过MAPAL的组合刀具以及精镗技术的高效配置,无需增加额外任何刀具,即可实现最佳的工艺结构并达到要求苛刻的形状和位置公差

- 大量标准系列整体硬质合金立铣刀可针对高挑战性难切削材料的摆线铣削提供高成本效益

- 软切削切向刀片具有更小的主轴功率消耗需求

泵外壳

爪

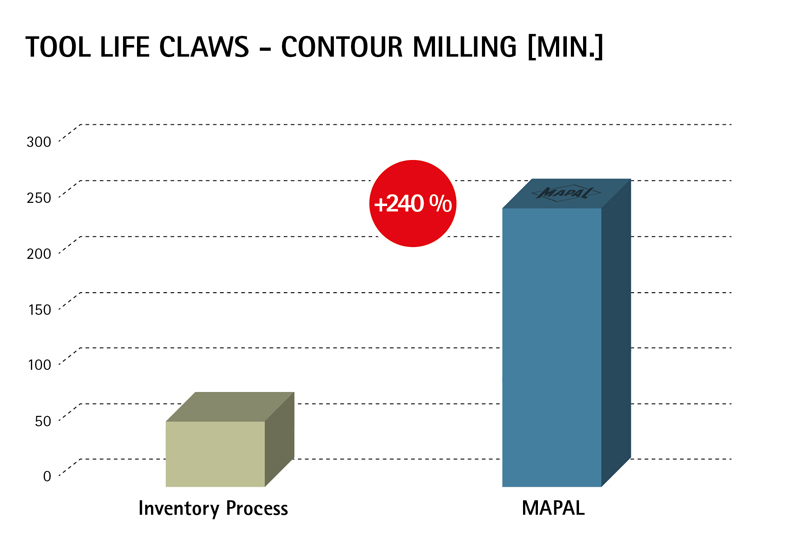

优点

- 高柔性化优势,适用于较大差异化结构件系列的加工,仅需一把刀具即可完成六种不同规格尺寸的系列化工件加工。

- 降低的刀具成本

- 针对爪的加工量大幅度减少

- 通过MAPAL刀具,实现整体加工流程的最佳化和高经济效益