用于大直径范围的多刃高性能铰刀

为了能够对大直径的孔用定义的公差进行精密加工,用户经常要面对这样一个问题:铰还是镗?专门应用于从 40 mm 直径起的加工,提供有高性能铰刀产品,具有个性化配置的可能性,可配HSK 刀柄和法兰刀柄。从带夹头的简单切削环到能在现场简单地更换刀片的高性能刀具 – 对于每种应用场合,MAPAL 都提供有合适的解决方案,用于对几乎所有的材料进行高精确和经济型加工。

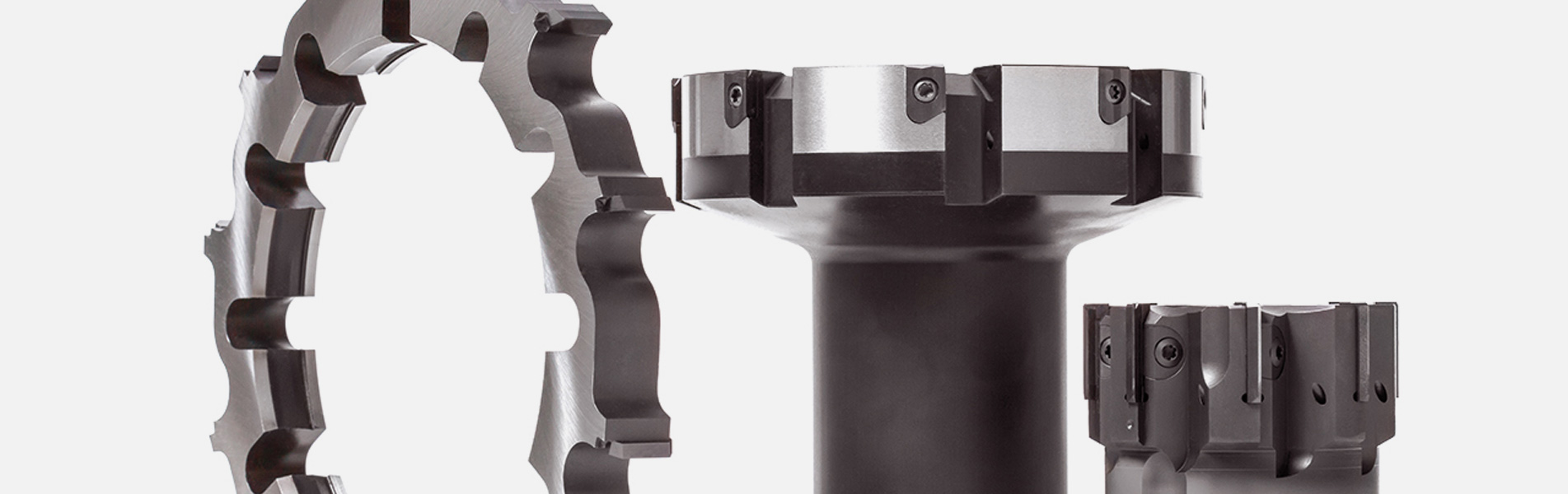

HPR400 plus

无需调整和四个切削刃明显降低了每件成本

通过高效益的重新制备提高经济性是HPR400 铰刀的开发重点。由于快速的应用数据和可以由客户在现场简单地更换刀片而使这种多刃刀具具有很高的经济性。由于高精度的刀片座使这些成为可能。由此而完全省去了运送给制造商的物流成本。使用在循环中的数量和重新制备成本都保持在一个很低的水平上。

为了在大直径零件的加工中进一步提高经济性,新开发的 HPR400 plus 的可转位刀片不再是单切削刃,而是采用了四切削刃的结构。因此使刀片材料得到了最佳的利用。MAPAL 生产加工的高工艺水平确保了四切削刃可转位刀片能够如此精确制造,使客户的员工能够在现场毫无问题地完成可转位刀片的转位和更换。因此,刀片的库存可以进一步减少,重新制备成本和每件成本能够进一步降低。

HPR400

可在现场简单地更换刀片。

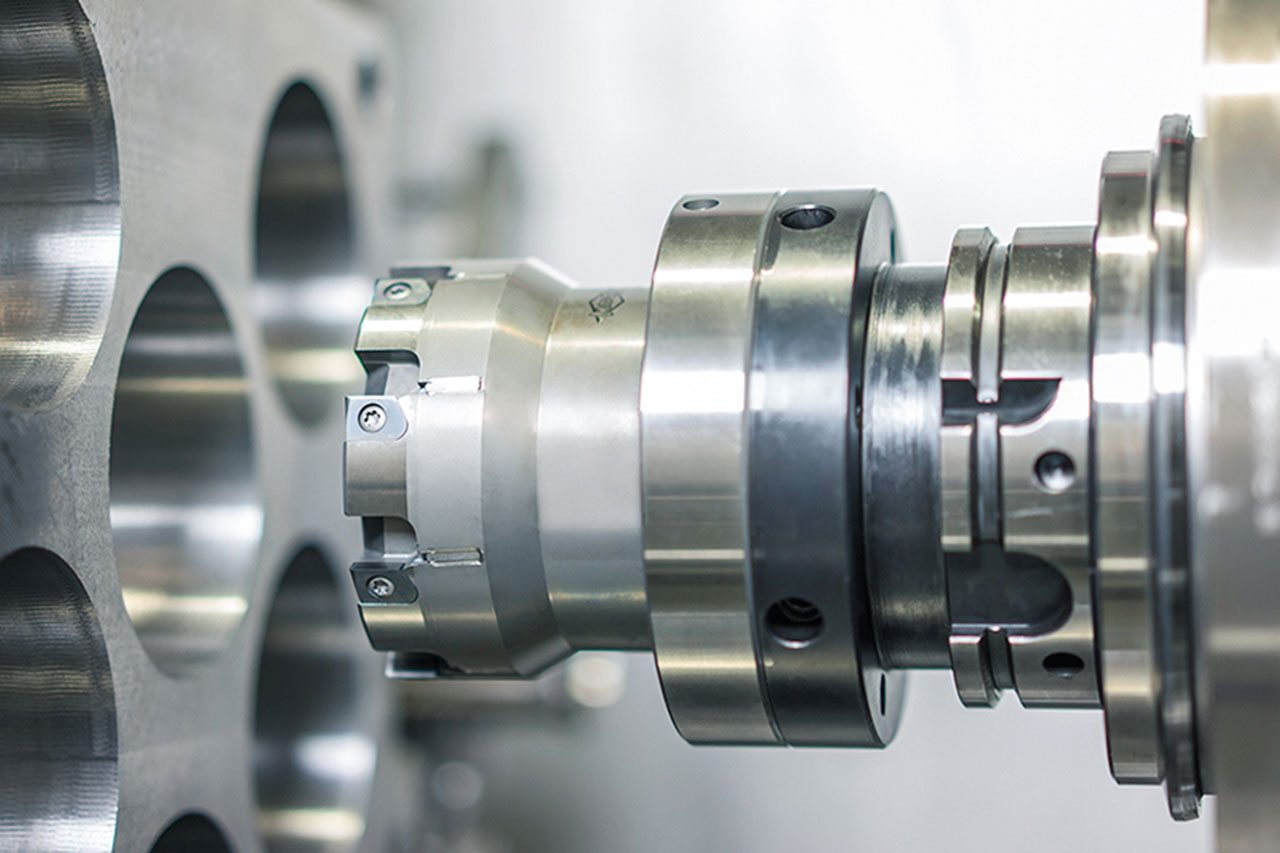

在 HPR400 系列中,由于专门的高精度刀片座的原因,用户可以自己在现场用一个扭矩扳手直接更换刀片。根本没有装错的可能,因为只有一种安装方位和可以把刀片安装在任意的位置上。因此,不仅省去了调整工作,而且也省去了送去进行重新制备的工作。用户仅需储备 MAPAL 的刀片即可。所需的刀具数量很少,因为不必另外准备刀体。用户仅用很少的工作量和很少的循环刀具数量,即可用 HPR400 铰刀获得高精度的孔。

刀片最佳地匹配于材料和加工条件。在65 至 400 mm 的直径范围内,可提供配置 HSK 刀柄,或者配置 MAPAL 自己的法兰刀柄的 HPR400 铰刀。MAPAL 提供有不同的刀片进行换片,这些刀片包括不涂层或化学涂层的硬质合金刀片、金属陶瓷刀片和带 PCD 或 PcBN 的刀片。

HPR300

通过创新的重新制备降低成本

MAPAL 凭借 HPR300 为客户提供了一种新的系统,在这种系统中,能够对固定的刀具快速且经济地重新换片和重新涂层。首先,把刀片作为毛坯刀片用夹紧爪稳固地夹紧在刀具中。接着,对直径和切削引导部的几何形状进行高精度的磨削。在刀片达到使用寿命后,需要进行重新制备时,可以简单且快速地用新的毛坯刀片取代已经磨损的刀片,然后再进行原装质量的 μ 级精度的磨削。HPR300 系统的另一个决定性的优点是,刀具的刀体和夹紧刀柄能够保持其原始的高精度不变。在更换刀片时,刀具的刀体没有热负载,也不需要进行繁复的清洁工作。钎焊的刀具平均能够最多进行四次重新制备,而 HPR300 铰刀最少也能够进行十次重新换片。如此,刀具仅在第一次重新制备后就已经分摊完毕,在整个使用寿命期内明显节约了成本,而且与钎焊刀具相比也没有降低性能。

MultiCut 切削环和刀柄

带相配的刀柄产品的切削环

带可调整切削环的 MAPAL MultiCut 铰刀能够完成孔的精加工,达到 IT7 的公差范围。这种系统的优点是,切削环的调整和测量操作特别简单,以及能够与不同的刀柄进行组合。可调整切削环以半个公差带的精度加工制成。