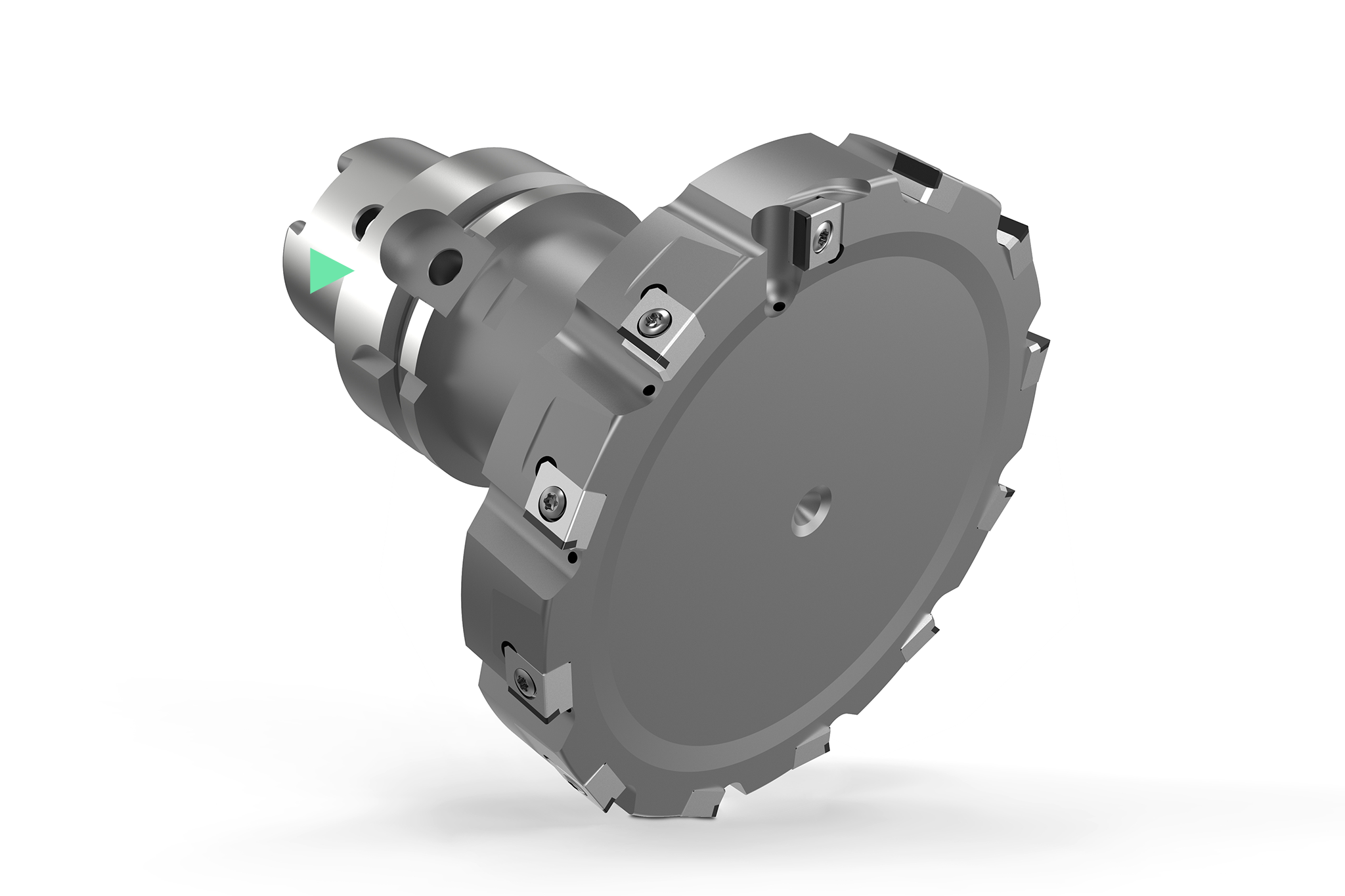

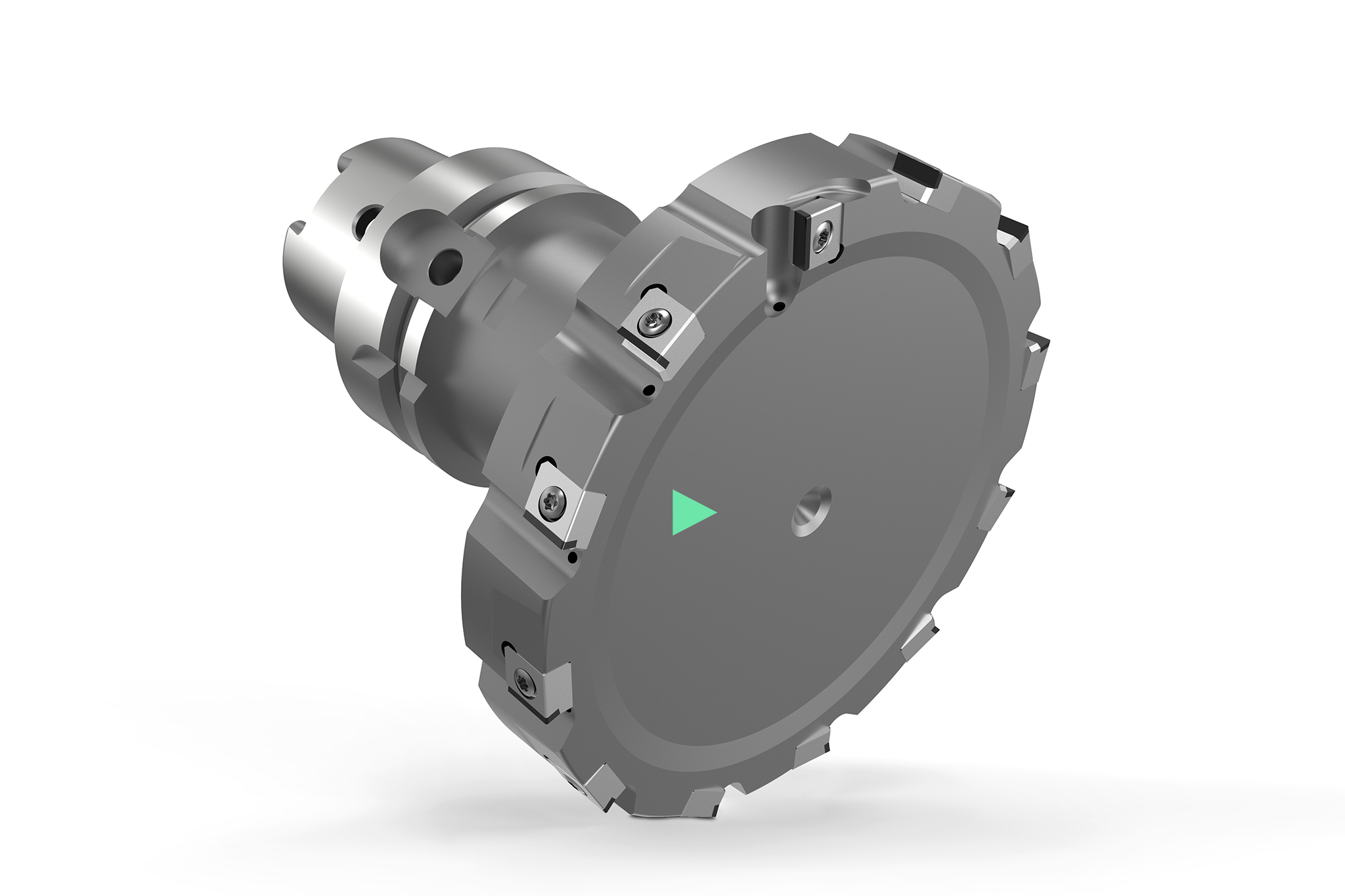

NeoMill-T-Finish型刀具

带有可转位刀片,用于铝材的精加工

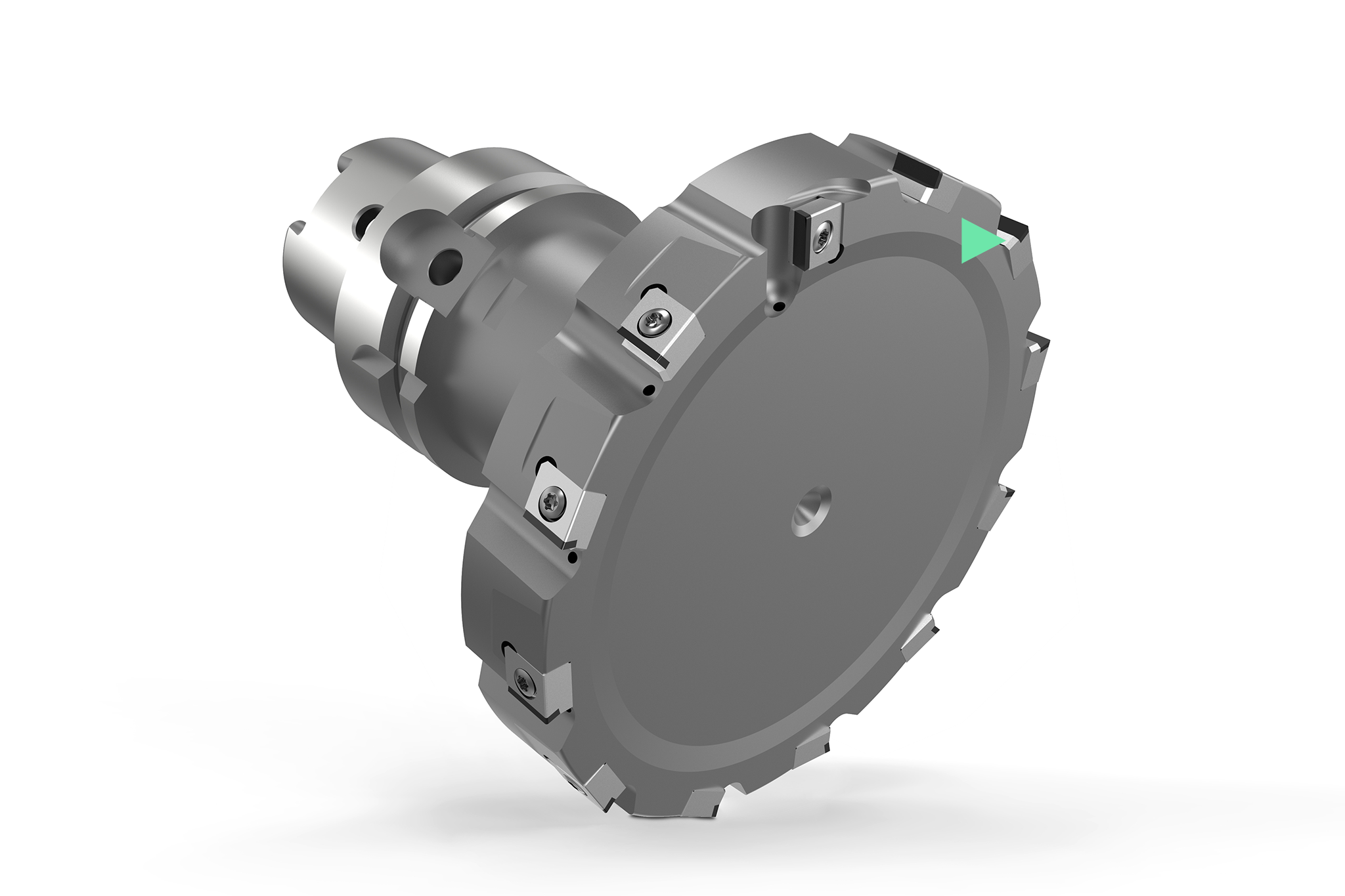

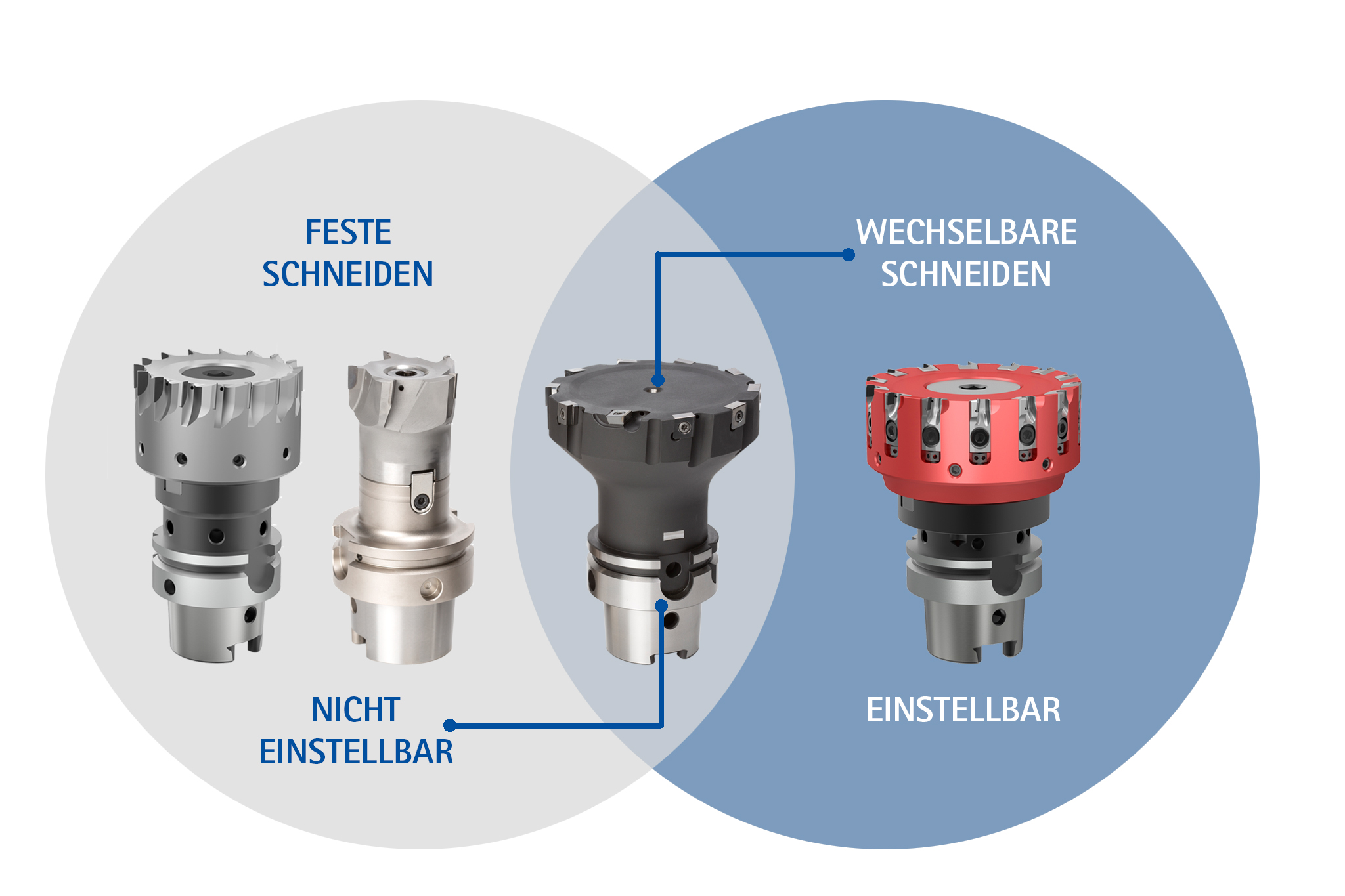

通过该把新型NeoMill-T-Finish刀具,MAPAL集团首次推出了带有可转位刀片的铣刀,用于铝材平面铣削的大批量加工。这款精加工铣刀,带有可互换的切削刃,根据Plug-and-play-即插即用-原理工作:客户可以直接在现场更换切削刃,无需进行事后调整。结果是可以减少刀具主体的必须购置保存量。

通过这种新型的系统化设计,除了配置PCD-聚晶金刚石切削刃的刀具之外,客户还可以根据用途和材料选用其它的切削刃材料,例如:无涂层的硬质合金或者施加有CVD-金刚石涂层、亦或是施加了PVD-涂层的硬质合金——均是可用于不同铝材加工的切削刃材料。

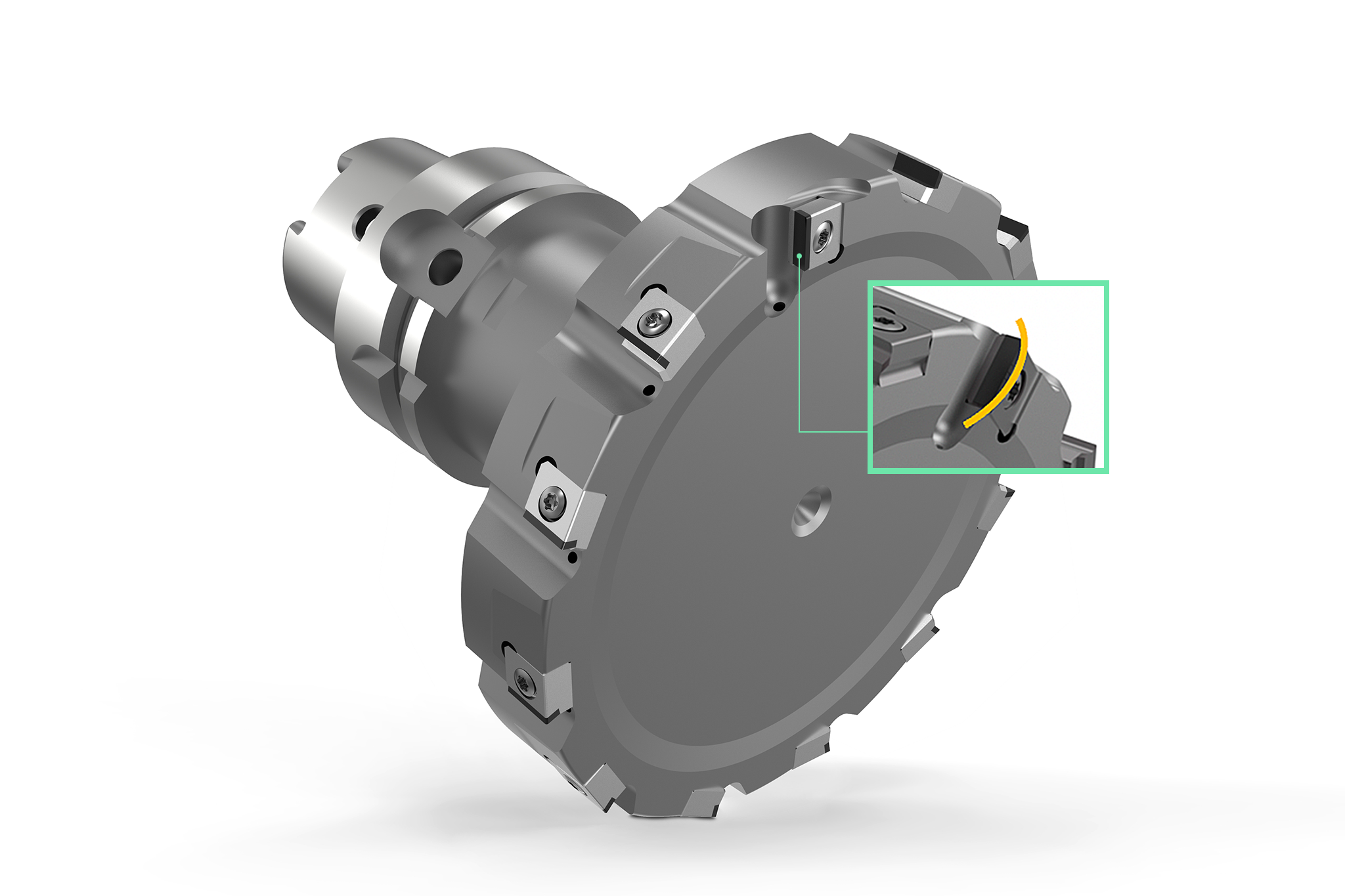

这款新型铣刀的刀片排列系统具有世界独一无二的特性,已经申请了专利。主切削刃被安装在圆周上,可去除可达 2.5mm的超大尺寸范围。配置有一个轴向设置的宽幅精加工切削刃,由它来实现精细到Rz = 1.5 µm的表面粗糙度。该创新性的系统可使切削刃形成均匀的磨损形态。

Configurable features

- Diameter range: 50,00-315,00 mm

- Cut surface: HSK, SK, CAT, BT

- Separation point: Milling arbor

- Number of tooth: Tool configuration and cutting data are defined for maximum efficiency and economy for each application

Plug & Mill principle

Scope of application

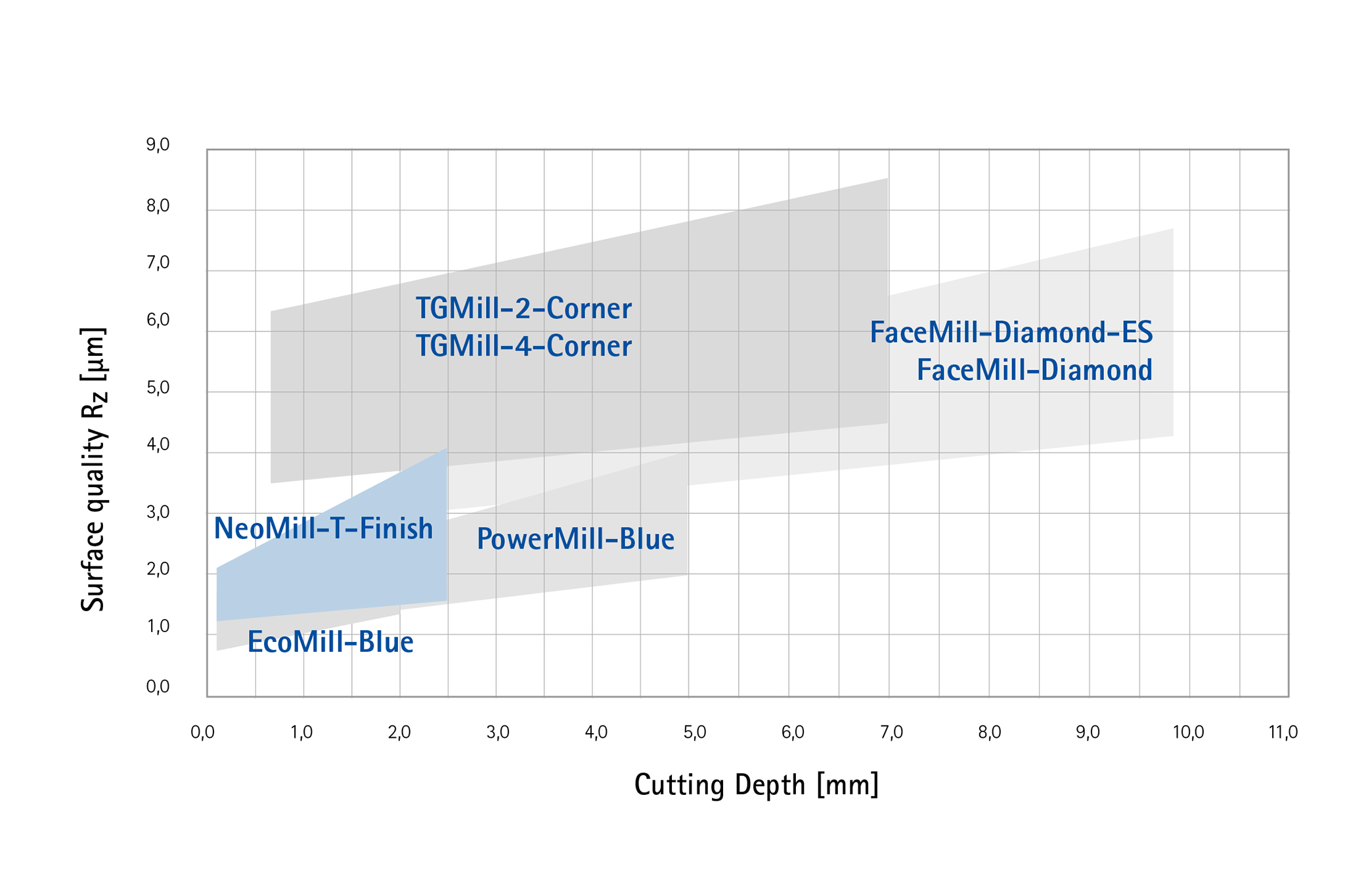

When selecting the optimum face milling cutter for aluminium machining, the surface finish to be achieved and the cutting depth play an essential role.