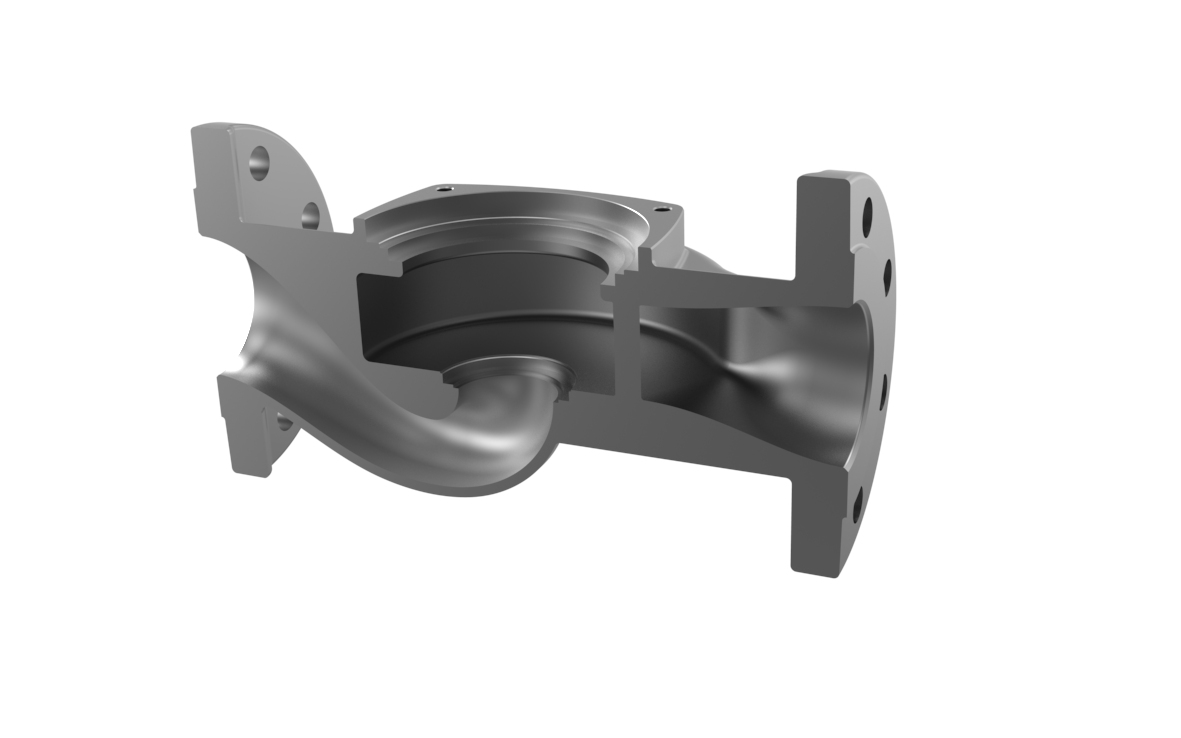

循环泵-外壳体

泵外壳体由欧标 EN-GJL-250 / 1.4301 (V2A) 铸铁制造

客户的初始情况

- 工艺流程非柔性化:在输送线上的径向滑阀-单元

- 在刀具交换和工件转换过程中,导致机床非加工辅助时间过长

- 要求:节拍时间更短、工件转换更快

- 在一台机床上加工所有差异化系列结构工件,需要高度的柔性化能力

本解决方案的特点

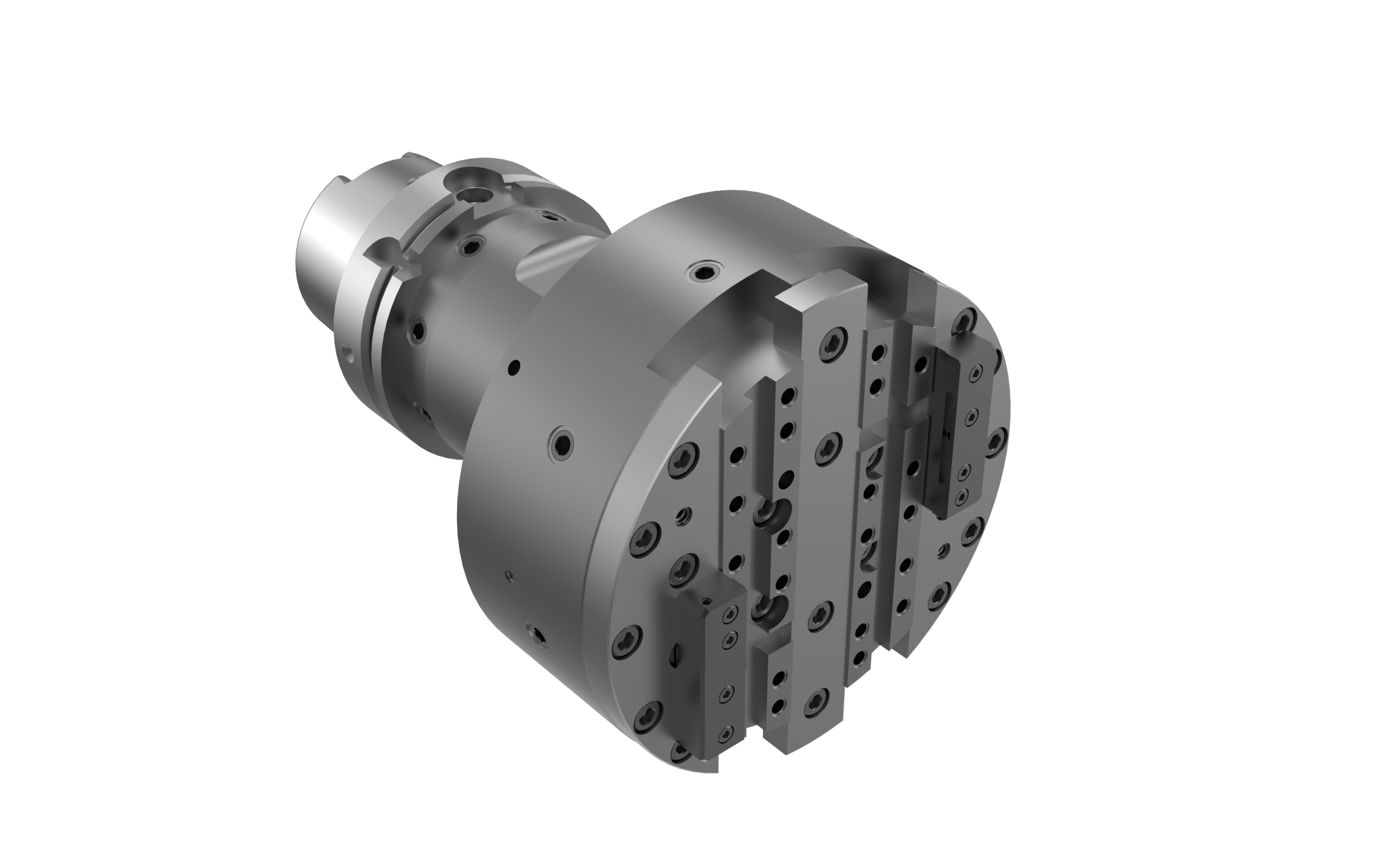

- 可自动换刀

- 通过姐妹刀具实现刀具设置不影响加工时间

- 高柔性化工艺,使用对刀仪进行预设置

- 快速换刀

- 可在同一主轴上应用标准刀具(如:钻头或者铣刀)

- 可转位刀片技术使得切削刃材料成本大大降低

- 与车床加工相比,由于z=2,使得加工循环时间大幅缩短

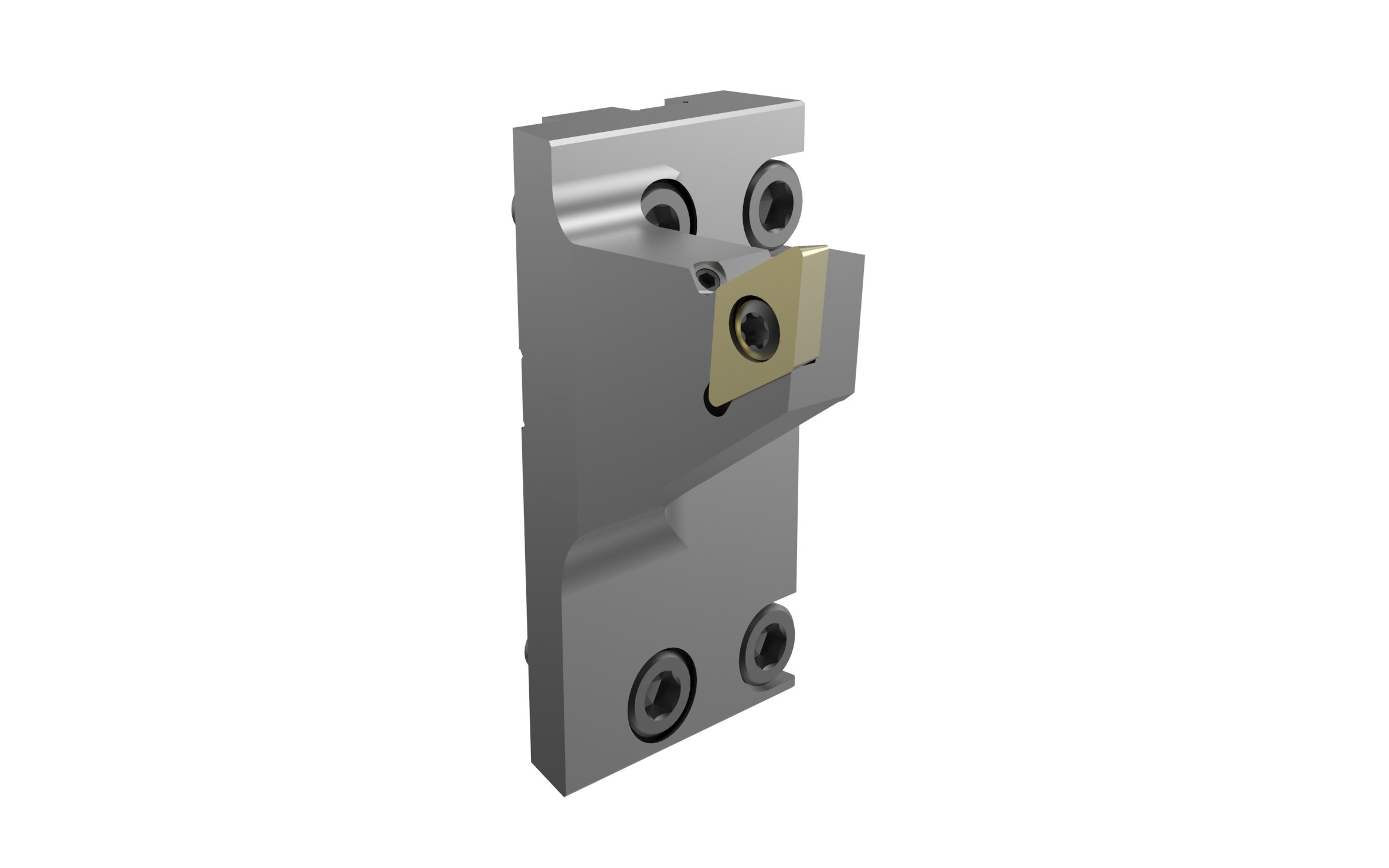

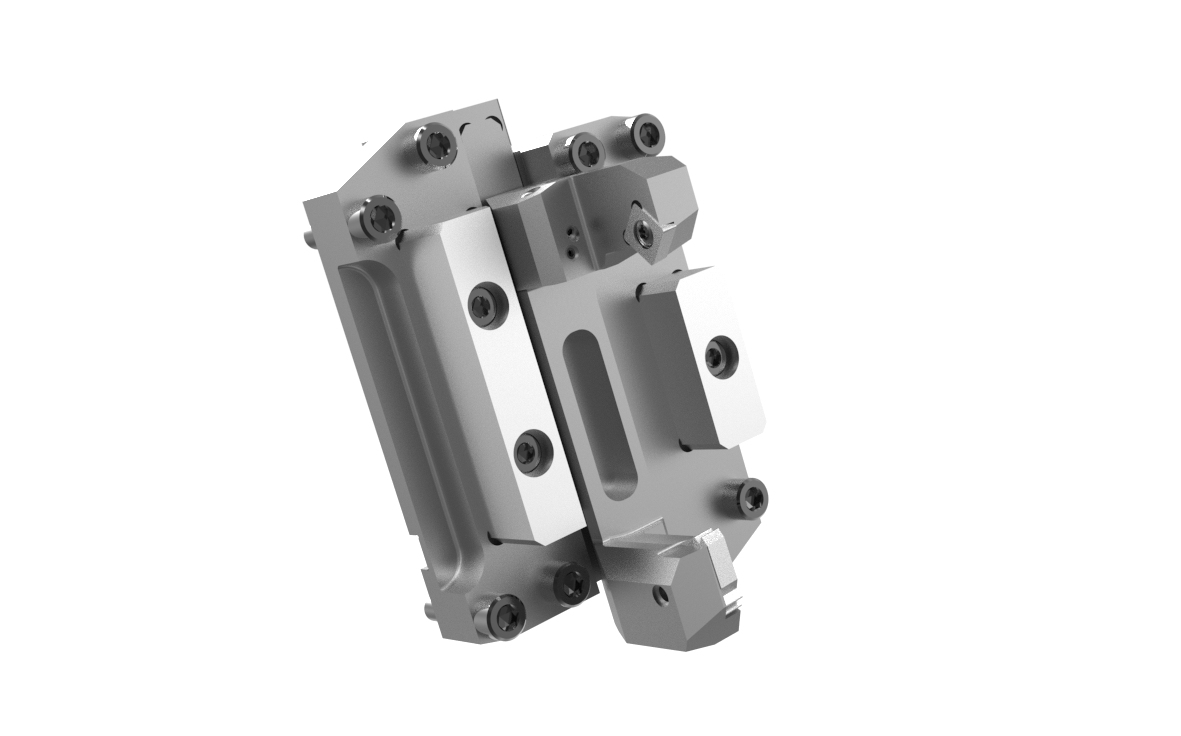

刀具亮点

针对回转U-轴-系统的调制刀具

- 柔性套装刀具,仅使用四种刀具类型,即可满足所有差异化结构组件系列的加工需求

- 刀片更换简单便捷,确保不同材料的加工易如反掌

- 通过可互换的HSK-接口以及刀库存储功能,实现了加工的最大柔性化

- 作为单滑块和双滑块设计结构

- 可使用姐妹刀具

内轮廓+平面加工

外轮廓+螺纹加工

![DOWNTIMES [MIN.] FOR PRODUCT CHANGES](/medias/sys_master/root/he9/h05/9687965368350/EN__Diagramme/EN-Diagramme.jpg)

优点

- 大幅减少更换工件和切削刃的停机时间

- 在批量加工中,大幅节省成本

- 只需要一种带可更换套装刀具的车端面刀头,即可应用于整个产品系列的加工

- 这些刀具可以在所有配备了U-轴或者Tooltronic®-驱动装置的机床上应用。

- 可实现在一台机床上,仅通过一次装夹即可完成整套加工

![DOWNTIMES [MIN.] FOR CUTTING EDGE CHANGES](/medias/sys_master/root/ha8/h09/9687965499422/EN__Diagramme2/EN-Diagramme2.jpg)