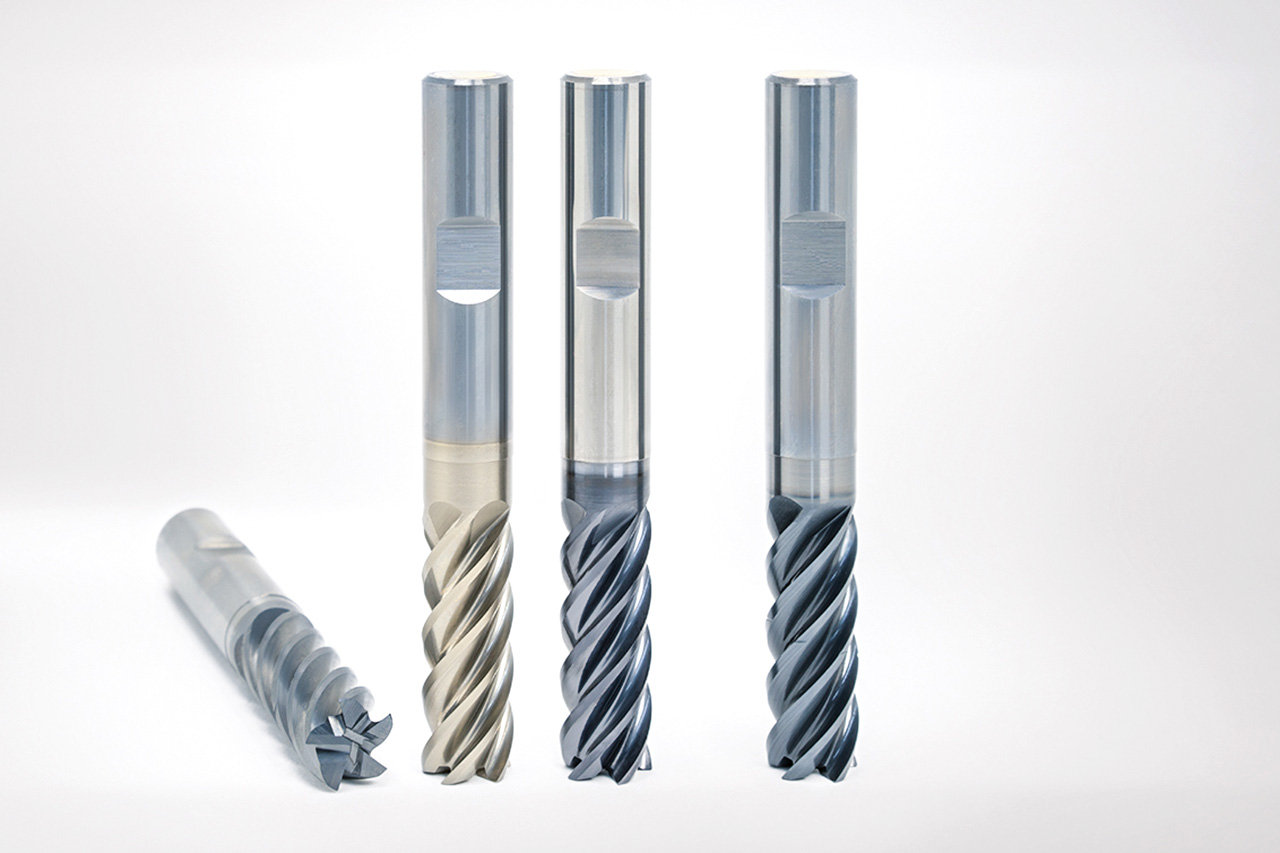

带固定刀片的立铣刀

MAPAL 的生产能力强的立铣刀系列 Opti-Mill 保证了在所有的加工任务中获得极优秀的结果和极高的流程安全性。经济性和产品质量在满足客户要求方面是备受关注的焦点。

- 面向应用

- 通过灵活性实现超前

- 总是正确的选择

产品总览

Rainurage et applications universelles

Fraises pour les applications universelles. Parfaitement adaptées au rainurage.

- Largeur de prise ae jusqu’à 1xD

- Plage de diamètres de 1 à 25 mm

- Modèles PCD jusqu’à 63 mm de diamètre

- Enlèvement de copeaux optimal

- Grand choix de longueurs et géométries pour toutes les applications

- Substrats haute performance et revêtements modernes pour d’excellentes durées de vie d’outil

Dressage – Ébauche

Pour obtenir un débit de copeaux maximal. Parfait pour le pré-usinage avec une grande surépaisseur.

- Grande avance (ae ~ 0,6xD)

- Plage de diamètres de 4 à 25 mm

- Nouveaux profils mortelés pour une répartition des efforts optimale sur l’arête de coupe

- Ébauche détalonnée

- Division angulaire inégale pour une coupe stable

Dressage – Finition

Parfait pour obtenir des surfaces de qualité exceptionnelle. Finition avec surépaisseur minime.

- Petite avance (ae ≤ 0,1xD)

- Plage de diamètres de 4 à 32 mm

- Nombre élevé de dents

- Répartition optimale des efforts de coupe

- Finition spéciale pour aciers trempés 50-65 HRC

Fraisage trochoïdal

Débit de copeaux maximal pour une excellente qualité de surface. Outil d’ébauche et de finition en un.

- Profondeurs de coupe allant jusqu’à 3xD

- Plage de diamètres de 4 à 25 mm

- Partie active extra longue

- Division angulaire inégale et partie active finement équilibrée pour ménager la broche machine et atteindre des durées de vie prolongées

- Enlèvement de copeaux optimal

- Utilisation avec un système CAM moderne

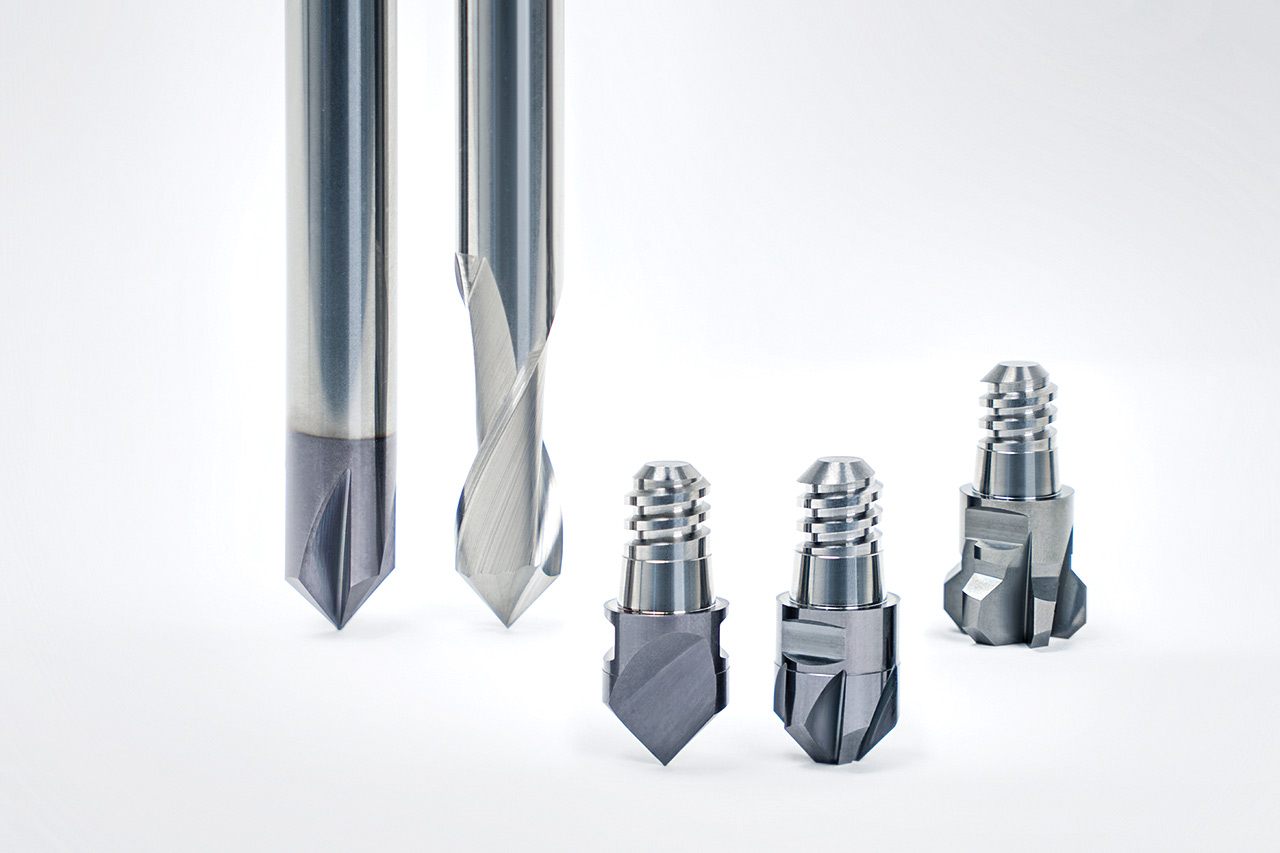

Fraisage à avances élevées

Spécialement pour fraisage à avances élevées et vitesses de coupe extrêmes.

- Faible profondeur de coupe (ap = 0,05xD)

- Plage de diamètres de 8 à 25 mm

- Avances maximales de 1,35 mm par dent pour 20 mm de diamètre.

- Plongée oblique et fraisage de poches même en cas de longs porte-à-faux

- Arrosage central pour dégagement copeaux optimal

Fraisage de profil

Contourner et copier à haute précision.

- Petite avance (ap ~ 0,1xD, ae ~ 0,1xD)

- Plage de diamètres de 1 à 25 mm

- Petits diamètres (à partir de 1 mm) spécialement pour fraiser l’acier à outil et les aciers trempés de 50 à 65 HRC

- Le maximum de précision pour la construction d’outils et de moules

- Tolérances extrêmes en cas de conception hémisphérique et de fraisage torique

Chanfreinage, ébavurage et fraisage-perçage

Chanfreiner et ébavurer les pièces ébauchées en toute rentabilité.

- Plage de diamètres de 3 à 20 mm

- Outil combiné pour le fraisage-perçage en un de notamment les tôles et les pièces à parois minces

- Modèles avec porte-outil pour têtes interchangeables pour le maximum de flexibilité et de rentabilité

Outils spéciaux sur mesure

- Réalisation de géométries et de contours complexes pour la quasi-totalité des applications

- Revêtements performants pour chaque matériau

- Regroupement de plusieurs outils standards pour un seul outil spécial performant