01.09.2018

OptiMill-Uni-Wave

A milling cutter for all occasions

Larger cutting depths, better chip removal and a higher material removal rate – these were the goals that MAPAL experts set themselves in the development of the new OptiMill-Uni-Wave roughing milling cutter. The result: a universal milling cutter that is particularly cost-effective due to its innovative geometry and high cutting values.

wear resistance and gives the tool extreme thermal shock stability.

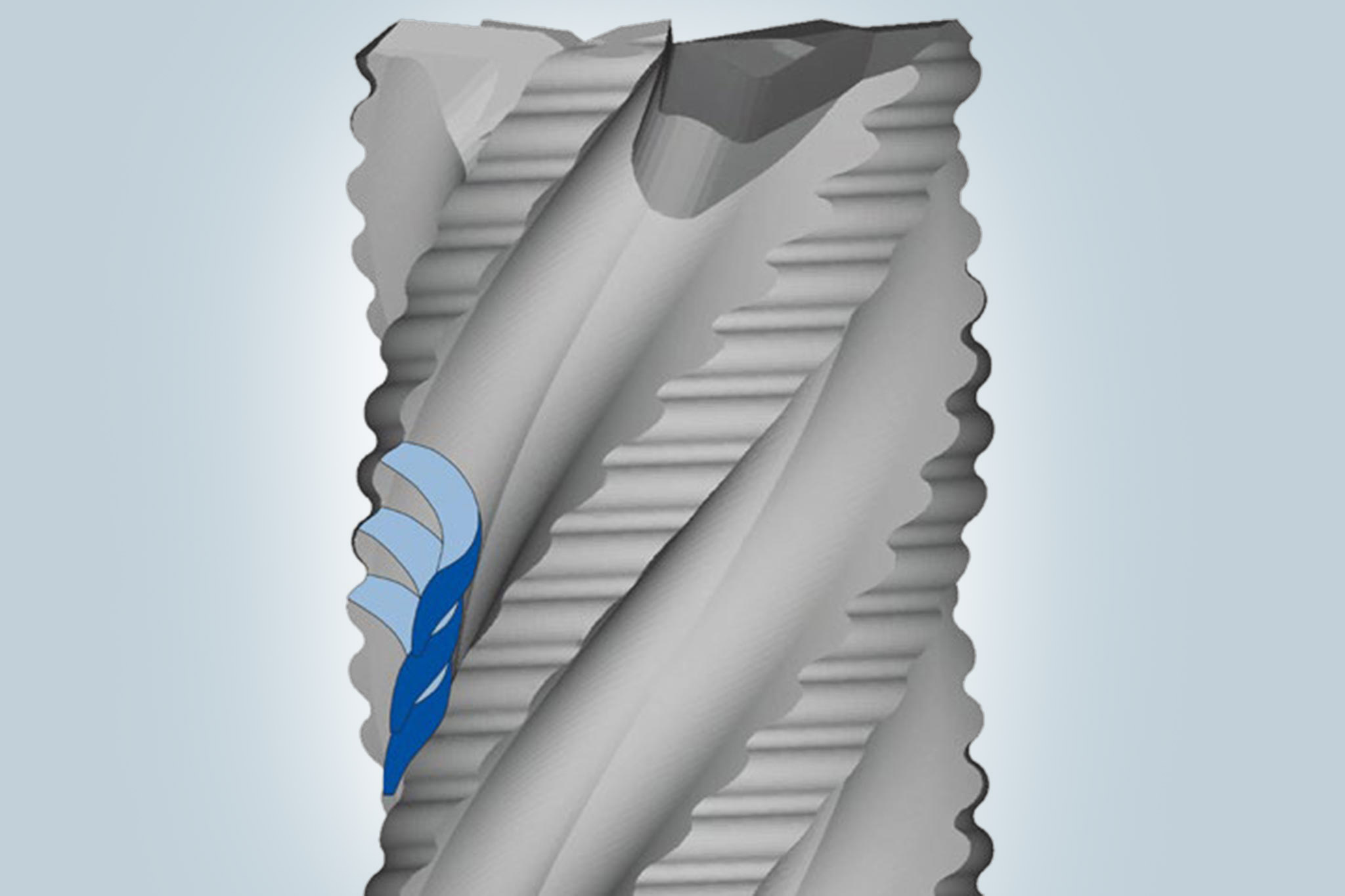

New geometry for optimum chip formation

material,” explains Krenzer. This geometry ensures perfect chip formation. Short, tightly rolled chips are produced during machining, which are reliably removed. In addition, the new geometry distributes the cutting forces very favourably, which enables high feeds per tooth. The radial forces are reduced and higher axial forces are applied. The rounding of the cutting edges protects them against chipping and therefore are particularly resilient and stable. In addition, the groove profile has been further developed.

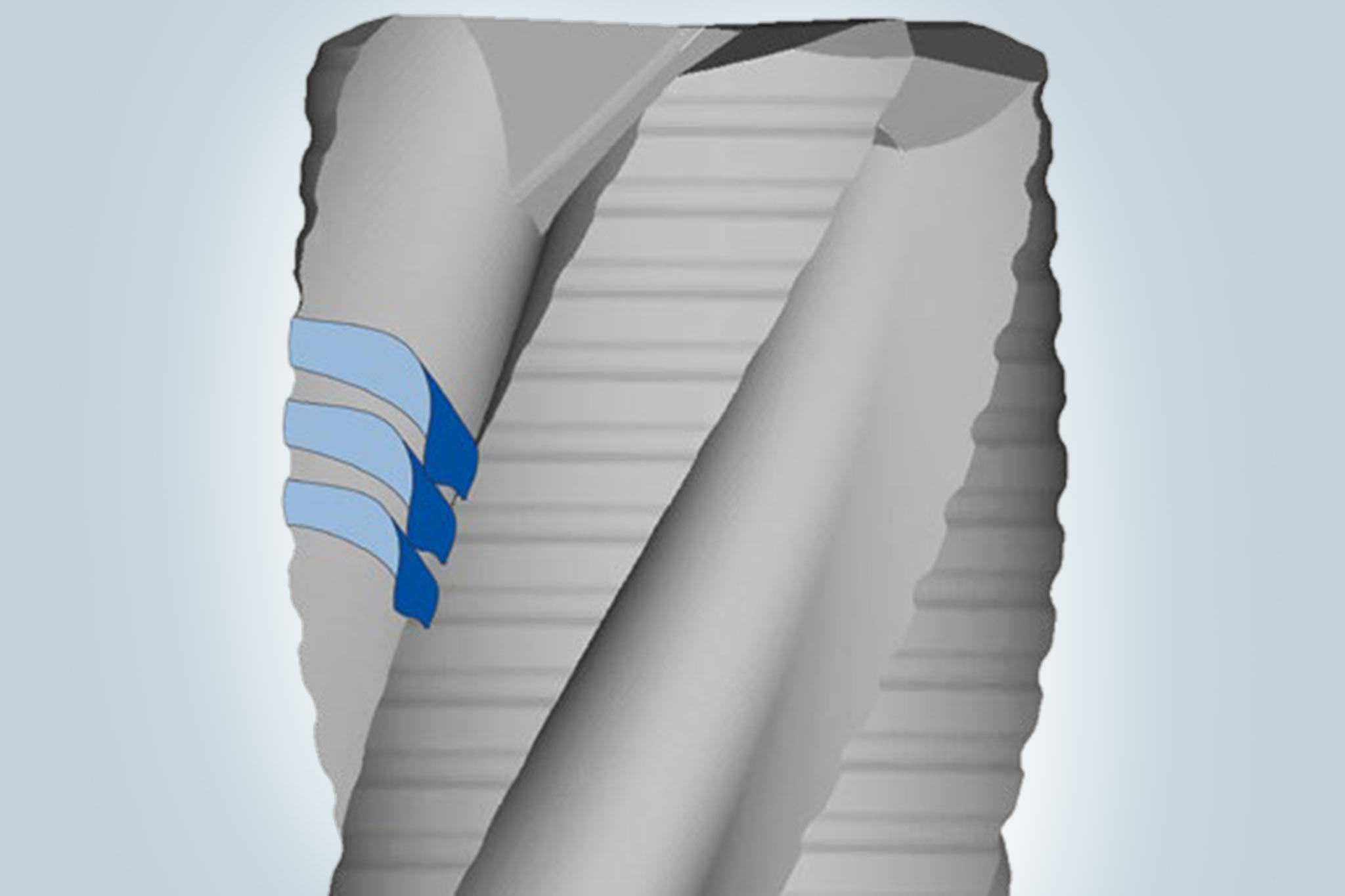

Imbalance for very smooth running

But that is not enough. “We took a close look at the entire geometry,” Krenzer explains. Both the

unequal spacing of the cutting edges and the unequal pitch of the tool ensure significantly

improved smooth running. “During machining with the redesigned OptiMill-Uni-Wave, we significantly reduced vibrations compared to other roughing milling cutters,” says the Managing

Director.

The results of the developments can be quantified:

- 30 percent better tool life in steel*

- 37 percent higher feed rate at significantly higher cutting depths (up to 2xD)*

- 15 percent lower spindle drive power due to lower cutting forces**

- 40 percent lower pull-out forces**

* compared to the OptiMill-Uni-HPC-Rough roughing milling cutter (in 42CrMoS4)

** compared with a milling cutter with straight cutting edges

Regrinding for maximum cost-effectiveness

The OptiMill-Uni-Wave can also be reground. “In order to make the best possible use of the

cost-intensive carbide, we recommend that the milling cutter be reconditioned exclusively by the manufacturer,” emphasises Krenzer. To exploit the full potential of the tools, re-grinding and

re-coating to original manufacturer quality are essential. Only then is it possible to guarantee reliable, consistent machining results and machining performance of up to 100 percent compared to a new tool. The risk of a tool fracture and the related risks of damage to the part or machine are minimised.