19.10.2023

Faster thanks to structure and agility

As Chief Technology Officer, Jacek Kruszynski has been responsible for product and market segment management as well as research and development since October 2021. The editorial team at IMPULSE spoke to the Chief Technology Officer about structures, development priorities and plans in the field of digitalisation.

Mr Kruszynski, you have restructured MAPAL’s Product and Market Segment Management and put it on a new footing. How has the new structure been received in the market? Are the projected benefits apparent yet?

An important goal was to become significantly faster, for example when configuring tools or whole machining processes. How did you achieve this goal?

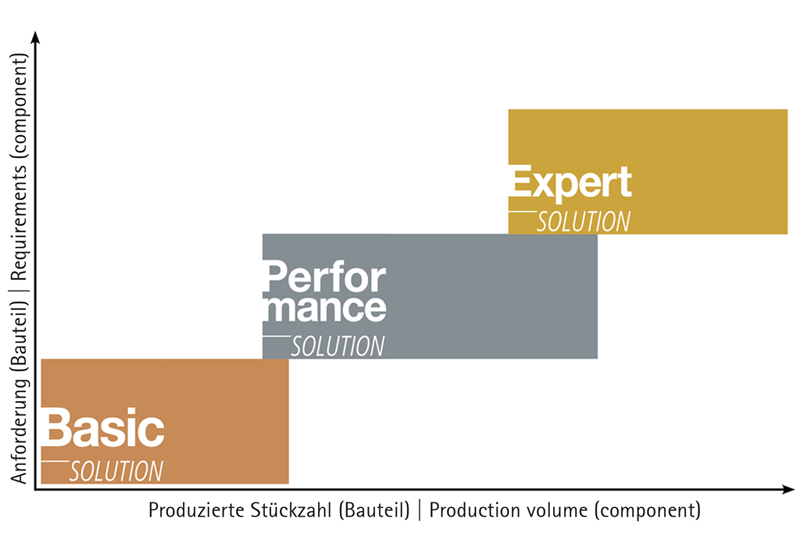

The requirements of individual markets and regions, and of individual customers in a region, vary considerably in terms of product volumes and quality requirements. The costs of a machining solution also play a role. We based our Basic Performance Expert classification on this requirements matrix, which we use to envisage application- and customer-specific machining solutions to a certain degree. With this approach, we meet our customers where they are in terms of production volume and quality requirements.

Incidentally, this classification has been in place for years for catalogue products. Carrying it over to components reflects our expertise in terms of customer-specific solutions. A basic solution is, put simply, designed for small series, for prototype production. However, this certainly doesn’t mean that the machining solution is “simple”. Of course, many standard tools are used here with the associated cost benefits. A highly complex custom tool used in the expert solution for mass production with high quality standards would never pay off in such a case. The classification provides a basic framework that our technical advisors can use to address specific needs.

MAPAL presented the Basic Performance Expert solutions on the stator housing for electric motors last year. Does this portfolio of sample solutions also exist for other parts?

What are the advantages of this classification for the customer? And for MAPAL?

MAPAL has always been known for getting the most out of “the last µm” for the individual customer. Does this new approach make the old one obsolete?

How are MAPAL’s focus markets developing?

What are the current development priorities?

In addition to a focus on process solutions for specific parts, MAPAL has consistently established and expanded its standard portfolio in recent years.

There is now an online shop with a range of products in stock. Why was this a vital step and what is your objective with standard products?

Standard tools supposedly make manufacturers directly comparable. How does MAPAL still impress?

In addition to customer-specific and standard tools, digital, data-based tools and solutions are now a vital third dimension that every tool manufacturer has to have. How does MAPAL handle this challenge?

We are of course working hard on digital solutions for our customers. In addition, we’re pushing ahead with increasing efficiency in our own production through digitalisation and automation. Providing a digital platform to discover a brand and its products is a requirement of today’s markets. This is also the case in our sector and has a big impact. There are many digital solutions nowadays. But in my opinion, there are hardly any “easy-to-use” solutions on the market. Of course, online shops and selection guides exist. MAPAL itself provides software solutions for tool management via c-Com, where we monitor the logistics and circulation phase as well as draw conclusions to optimise tools. When it comes to comprehensive solutions though, there’s actually still plenty of room for improvement. These assume that customers are willing to open up their production facilities to us or, more generally, to suppliers, and that they are prepared to enter into in-depth partnerships.

The basic prerequisite for everything digital is, of course, the database. It has to be right. All of our products have to be ready for digitalisation. Various formats and platforms play a role. Due to the importance of this issue, we’ve recently created the new Product Automation department, which takes care of all matters relating to the digitalisation of our products and structures and creates and maintains the digital twin across the individual processes. Incidentally, we have been able to fill many of the advertised positions in-house. I’m particularly pleased about that. We have these specialists at various sites in our organisation, who also know MAPAL and can work productively straight away. As a result of pooling resources and skills, I hope to see lots of synergy and an acceleration in this area.

What are your objectives for the next five years?

Thank you for the interview.

Contact

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Phone: +49 7361 585 3342