Bloc de commande hydraulique

Bloc de commande hydraulique 9SMn28k/EN-AW6082

Situation initiale du client

- Commandes individuelles, petites et moyennes quantités

- Grande variation des composants et des matériaux

- Temps de passage moindre

- Exigences de qualité élevées en matière de surface et d'absence d'arêtes

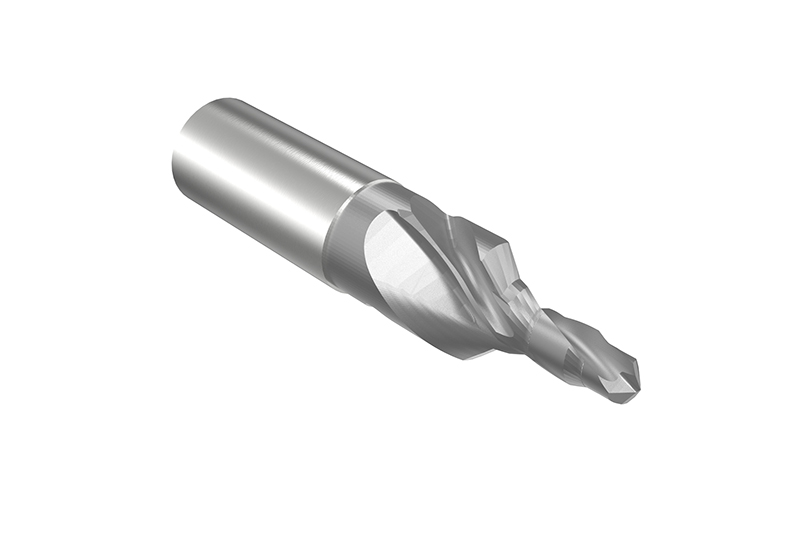

Special features of this solution

- Different workpiece materials can be machined with a single tool body → Insert solution allows maximum flexibility for small lot sizes

- Tool breakage avoided when producing overlapping oil channel bores

- Secure chip control when machining long-chipping material

- Efficient multi-stage tool → Reliable production of form and position tolerances

Valve bore

Oil bore

![TOOL LIFE OIL CHANNEL DRILLING [DRILLING HOLES]](/medias/sys_master/root/hf3/h2f/9175133159454/Grafiken__EN2/Grafiken-EN2.jpg)

Vantagens

- As etapas ideais do processo asseguram a máxima produtividade e os menores tempos de processamento

- As ferramentas combinadas eliminam o uso de outras ferramentas quando há grande variação de peças e materiais e locais de trabalho limitados

- Soluções de ferramenta multiuso em diversos componentes para furos de válvula e de conexão

- Amplo portfólio padrão que assegura usinagens fáceis e rápidas para pequenas produções e na construção de protótipos

![MACHINING TIME PER VALVE BORE [SEC.]](/medias/sys_master/root/h04/h33/9175133224990/Grafiken__EN3/Grafiken-EN3.jpg)