Durchstarten im Werkzeug- und Formenbau

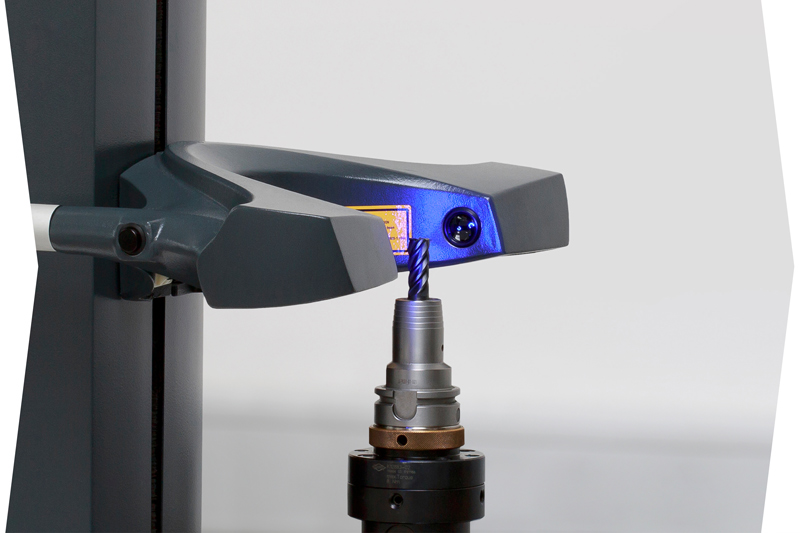

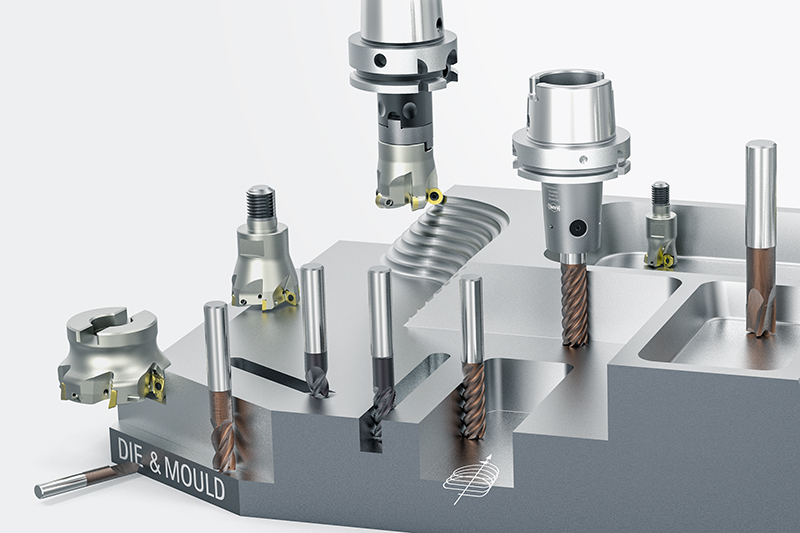

Genau diese Aspekte sind es, die MAPAL in Branchen wie der Automobilindustrie, dem Maschinenbau oder der Luftfahrtindustrie erfolgreich machen. So ist es nur folgerichtig, dass der Präzisionswerkzeughersteller nun auch im Werkzeug- und Formenbau effiziente und wirtschaftliche Lösungen für den kompletten Zerspanungsprozess anbietet. Vielseitige und präzise Hochleistungswerkzeuge und spezielle Werkzeughalter mit schlanken Konturen und präzisem Rundlauf minimieren Polieraufwand und Nacharbeit durch eine konstante Oberflächengüte beim Fräsprozess.

Werkzeugprogramm für den Formenbau

Komponenten & Werkstoffe

- Stahl und gehärteter Stahl

-

Stahl und gehärteter Stahl

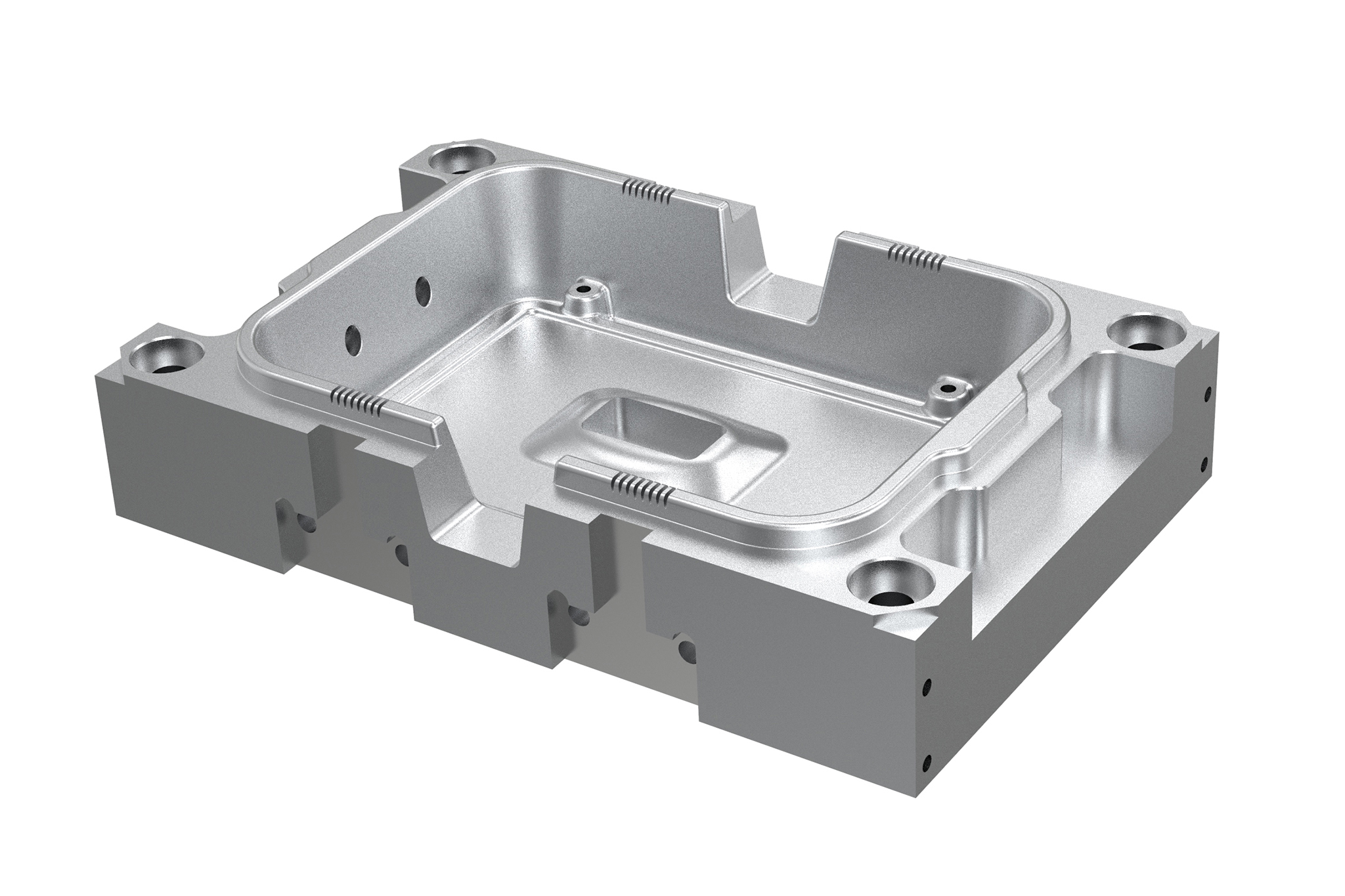

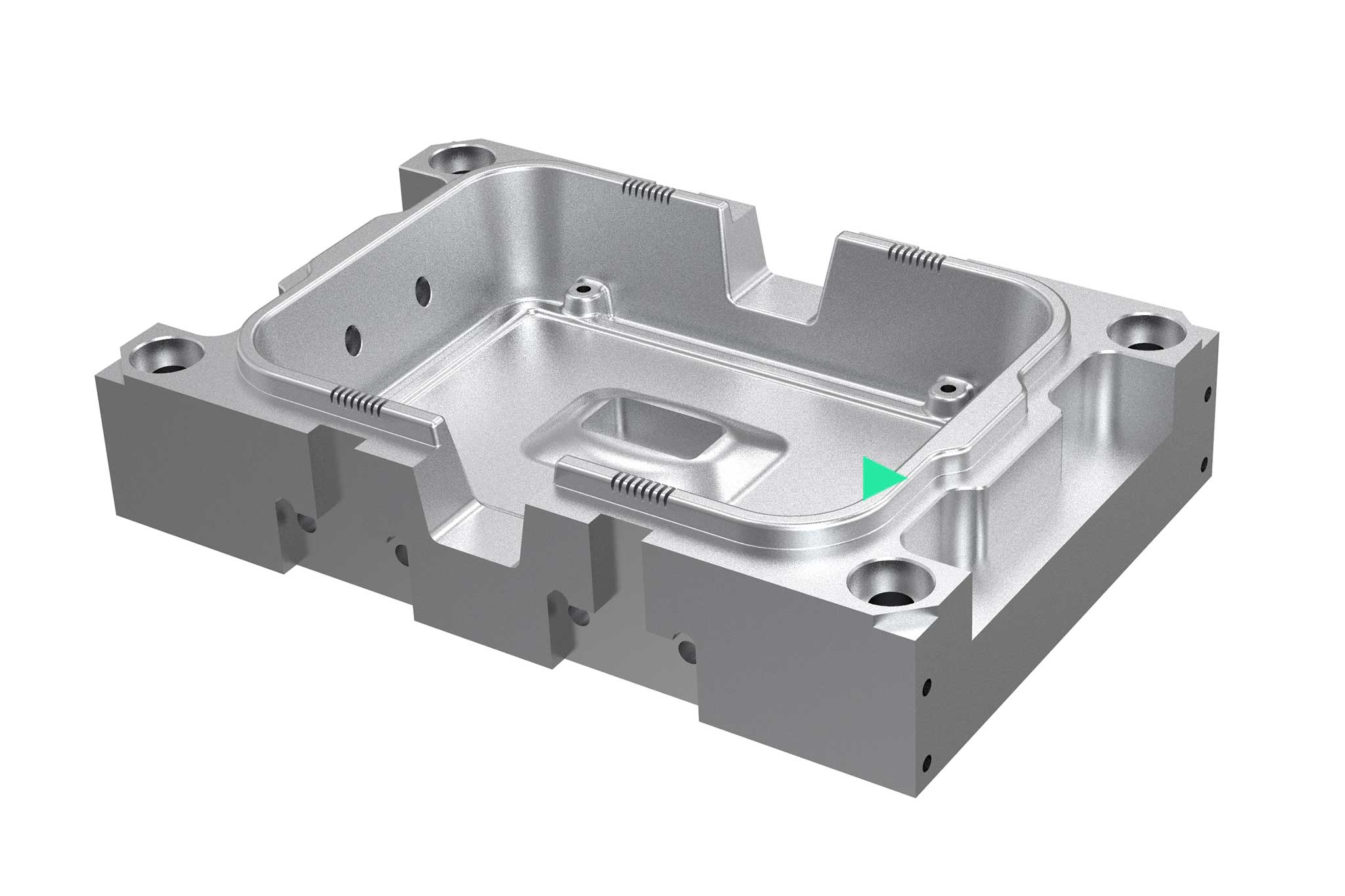

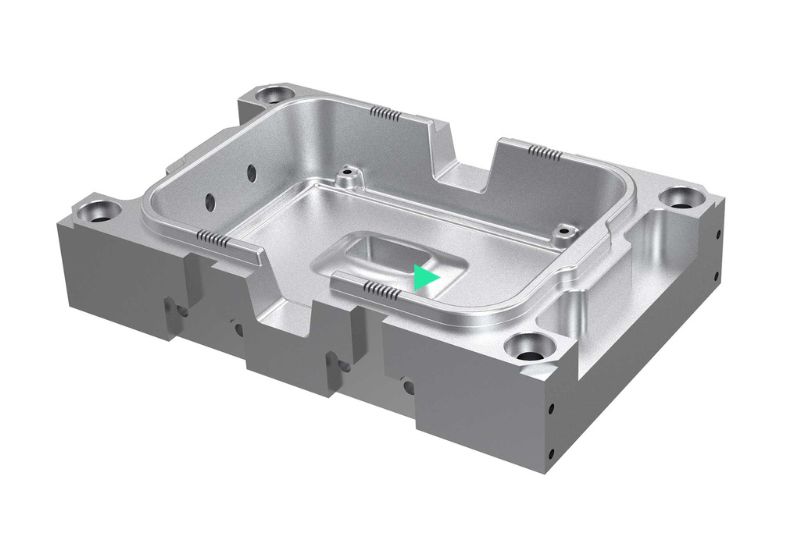

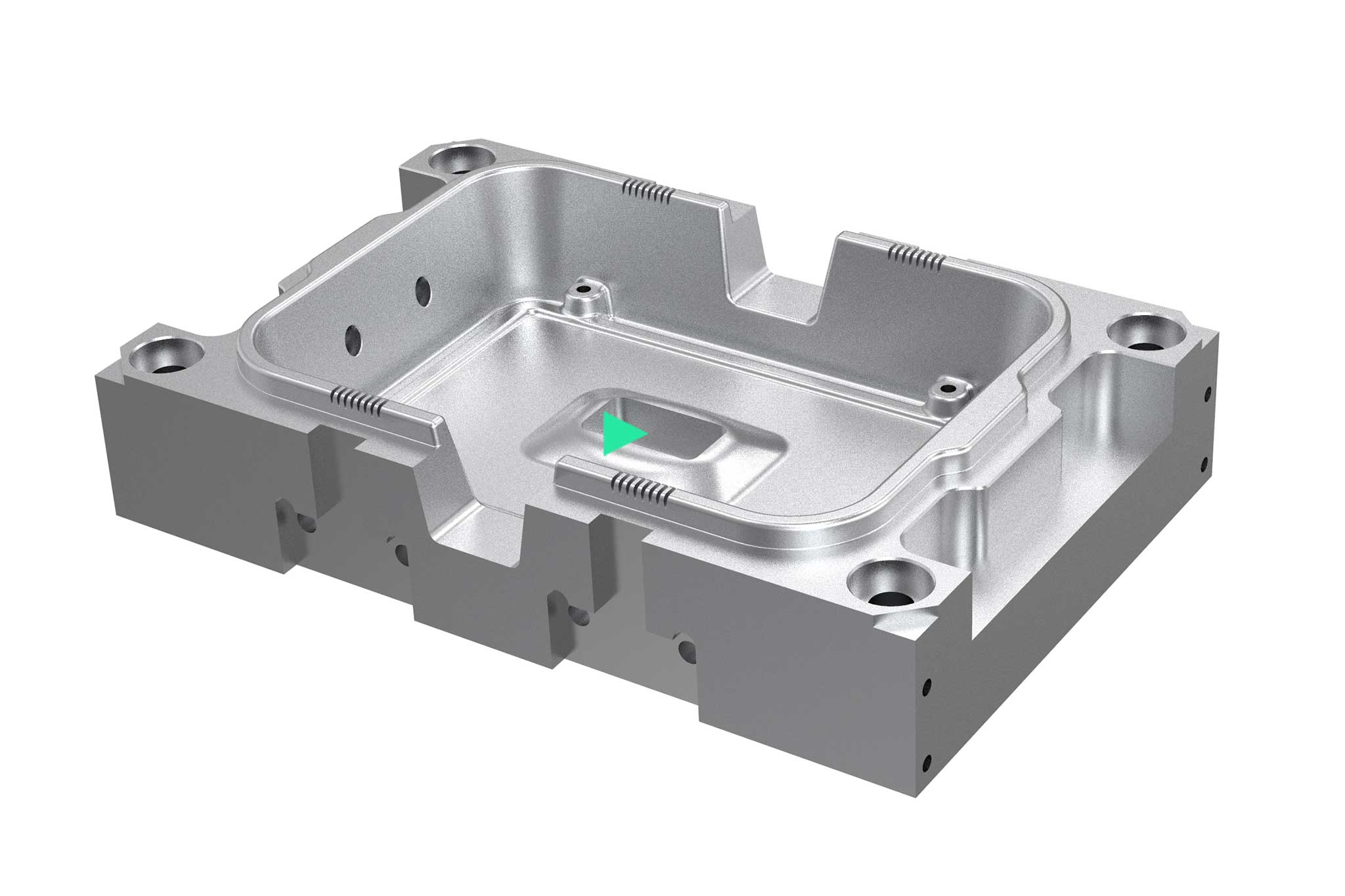

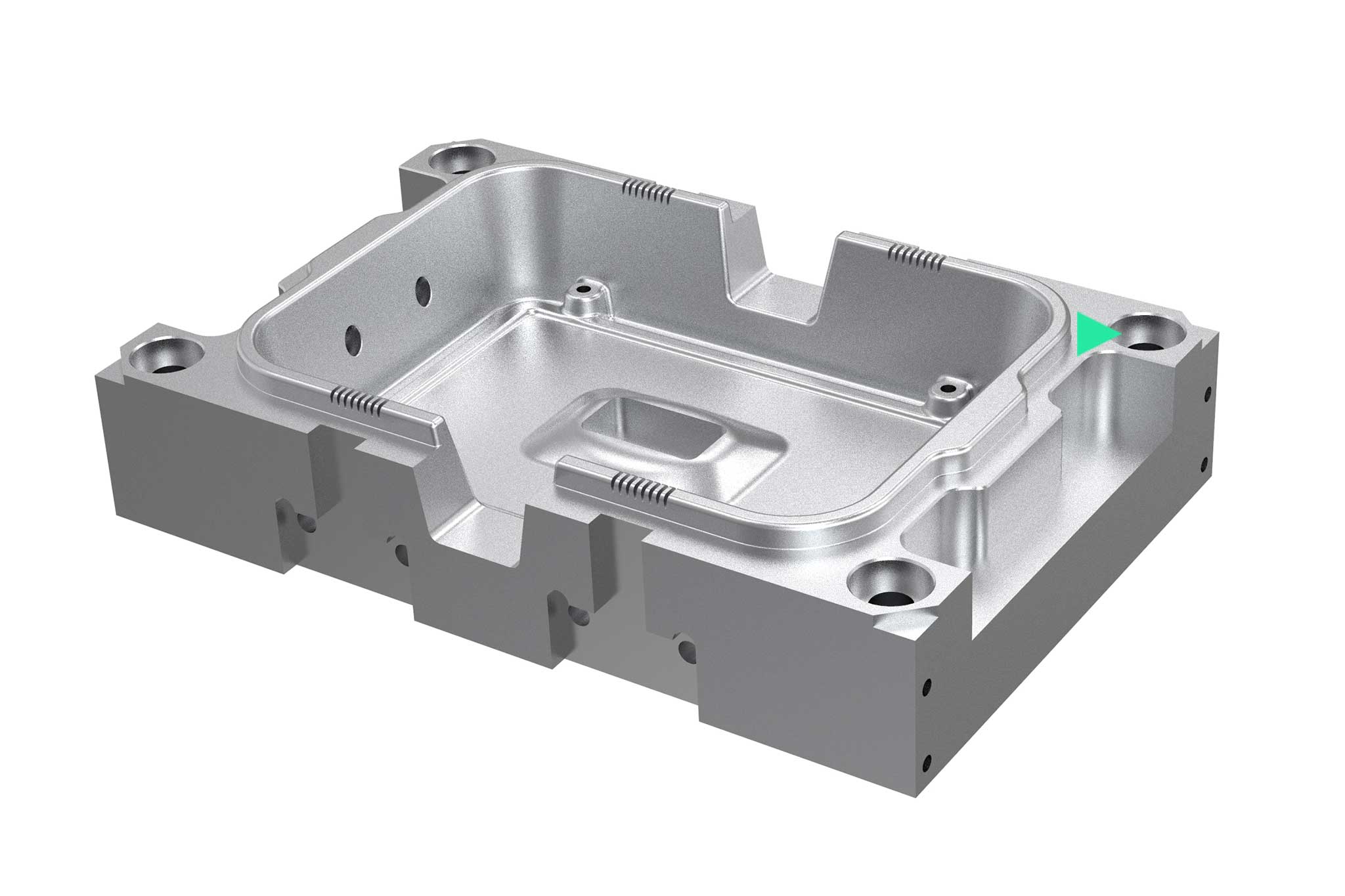

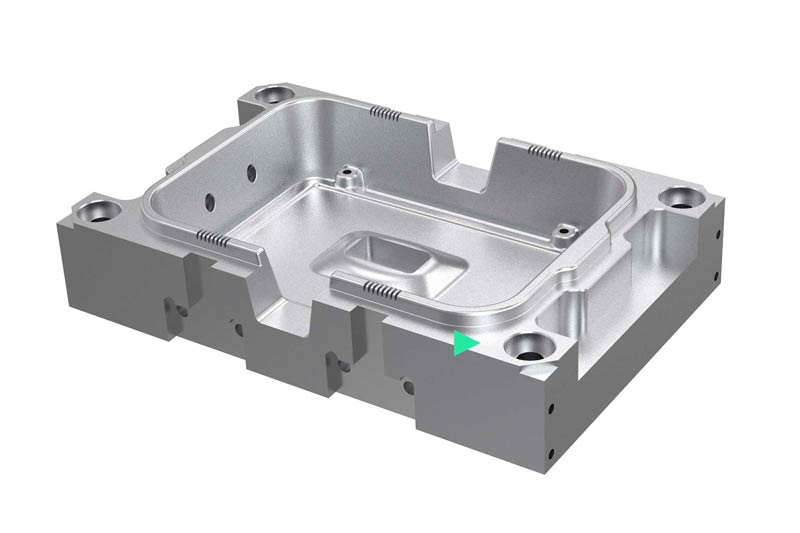

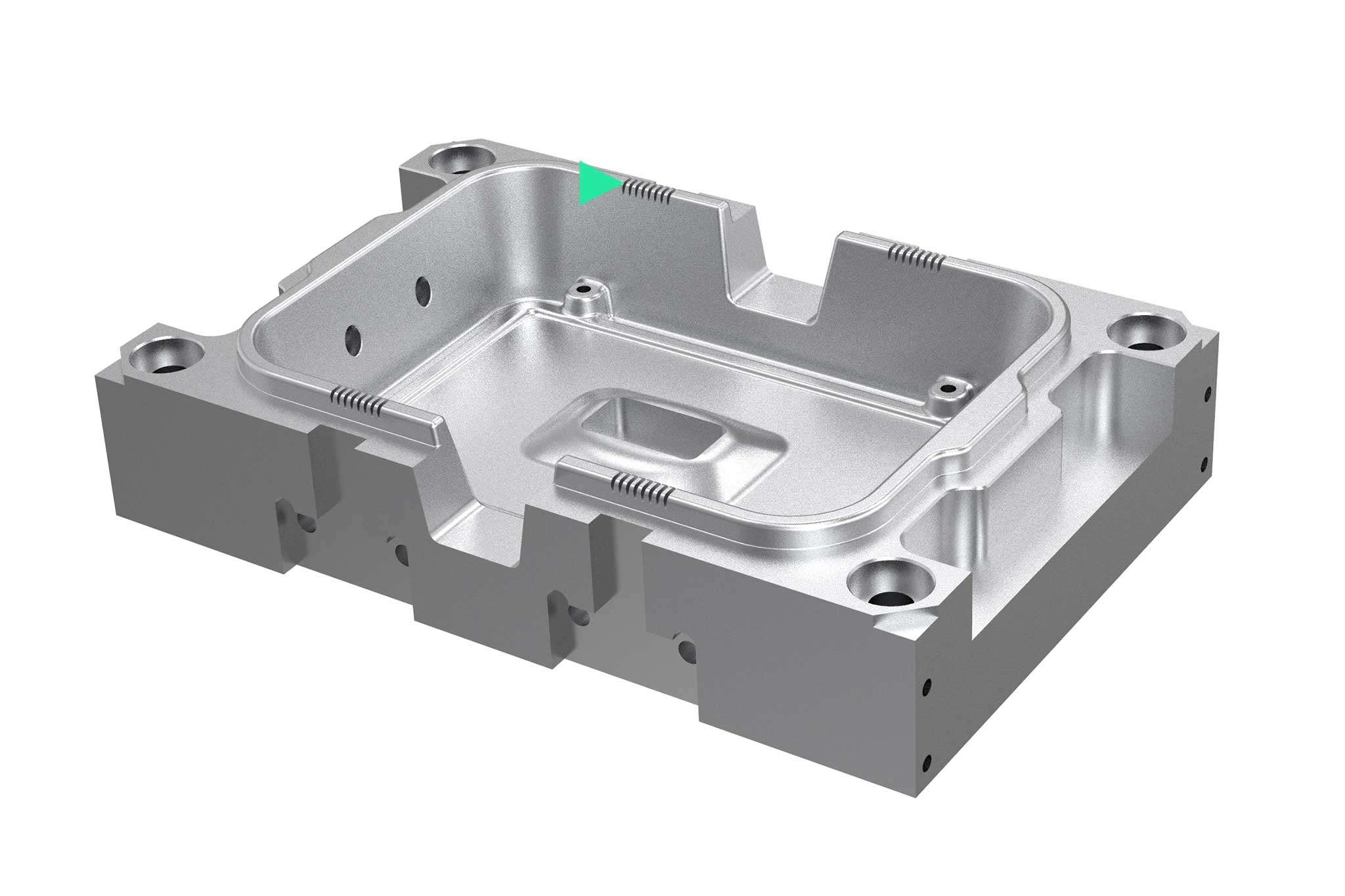

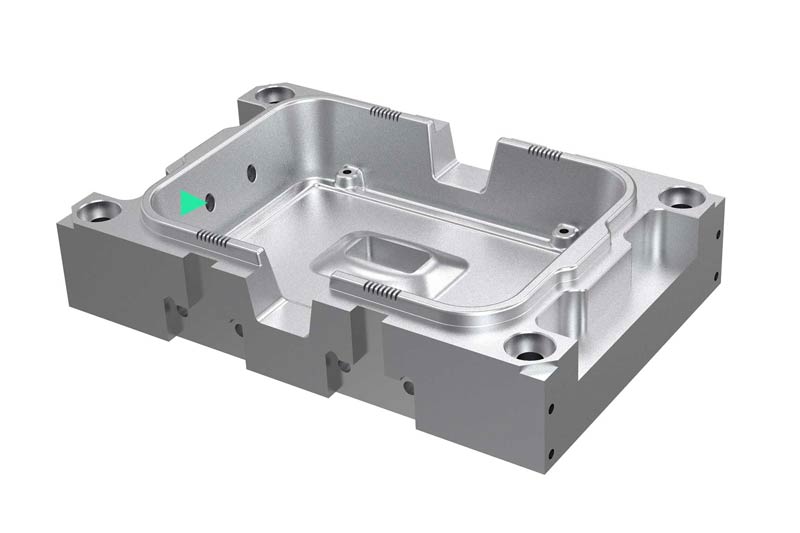

Immer komplexer werdende Bauteile mit zunehmend tiefen Kavitäten sowie Form und Versteifungsrippen bei Kunststoffspritzguss- und Druckgussformen machen den Einsatz extra langer Werkzeuge mit teils sehr kleinen Durchmessern nötig. Komplexe Teilegeometrien und unterschiedlichste Materialbeschaffenheiten stellen höchste Anforderungen an die Bearbeitung und Werkzeugstandzeit.

Anwendungsbeispiele:

- Spritzgussform

- Druckgussform

- Gusseisen

-

Gusseisen

Bei der Konstruktion, des Engineerings und des Baus von Kaltumformwerkzeugen mittlerer und großer Größe wird aufgrund von Materialeigenschaften wie Druckfestigkeit und leichte Zerspanbarkeit häufig Gusseisen verwendet. Hauptkomponenten sind hierbei Formplatten und Formeinsätze. Hier bringt MAPAL bei Fräs- (2D und 3D) sowie Bohrbearbeitungen (Bohren, Reiben, Gewindeschneiden) große Erfahrung mit.

Anwendungsbeispiele:

- Formplatten

- Formeinsätze

- Aluminium

-

Aluminium

Wenn es um Vorserien- oder Prototypenformen geht, ist es nicht ungewöhnlich, leicht zu zerspanende Materialien zu verwenden. Häufig kommen Aluminiumlegierungen oder Uriol (Kunststoffe) zum Einsatz. In diesen Fällen sorgen Vollhartmetallwerkzeuge mit positiven und teilweise polierten Schneidkanten, noch besser PKD bestückte Werkzeuge für eine hohe Produktivität und kurze Bearbeitungszeiten.

Anwendungsbeispiele:

- Vorserienformen

- Prototypenformen

- Kupfer

-

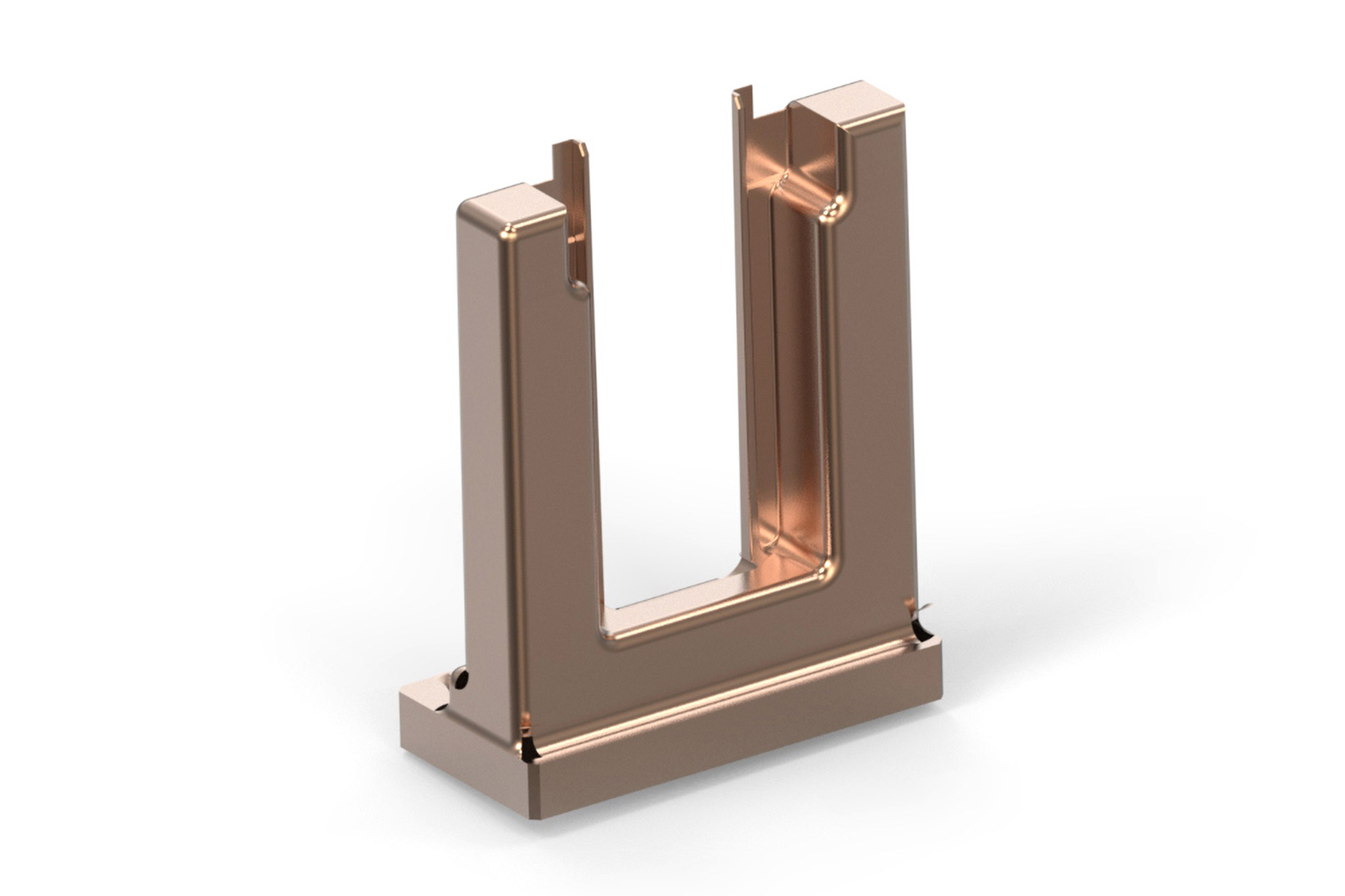

Kupfer

Die Herstellung der Elektroden für EDM Prozesse erfordert die Bearbeitung von Kupferlegierungen und Graphitwerkstoffen. Die Wahl des Elektrodenwerkstoffes richtet sich nach den Anforderungen der herzustellenden Form. Kupferlegierungen sind vergleichsweise teuer und werden im Allgemeinen bei Elektroden zur Endbearbeitung verwendet, wenn es um hohe Oberflächenqualität und Formgenauigkeit geht. Vollhartmetallschaftfräser mit speziellen Geometrien von MAPAL garantieren hier hochpräzise Bearbeitungsergebnisse.

Anwendungsbeispiel:

- Elektroden zum Funkenerodieren (EDM Prozesse)

- Graphit

-

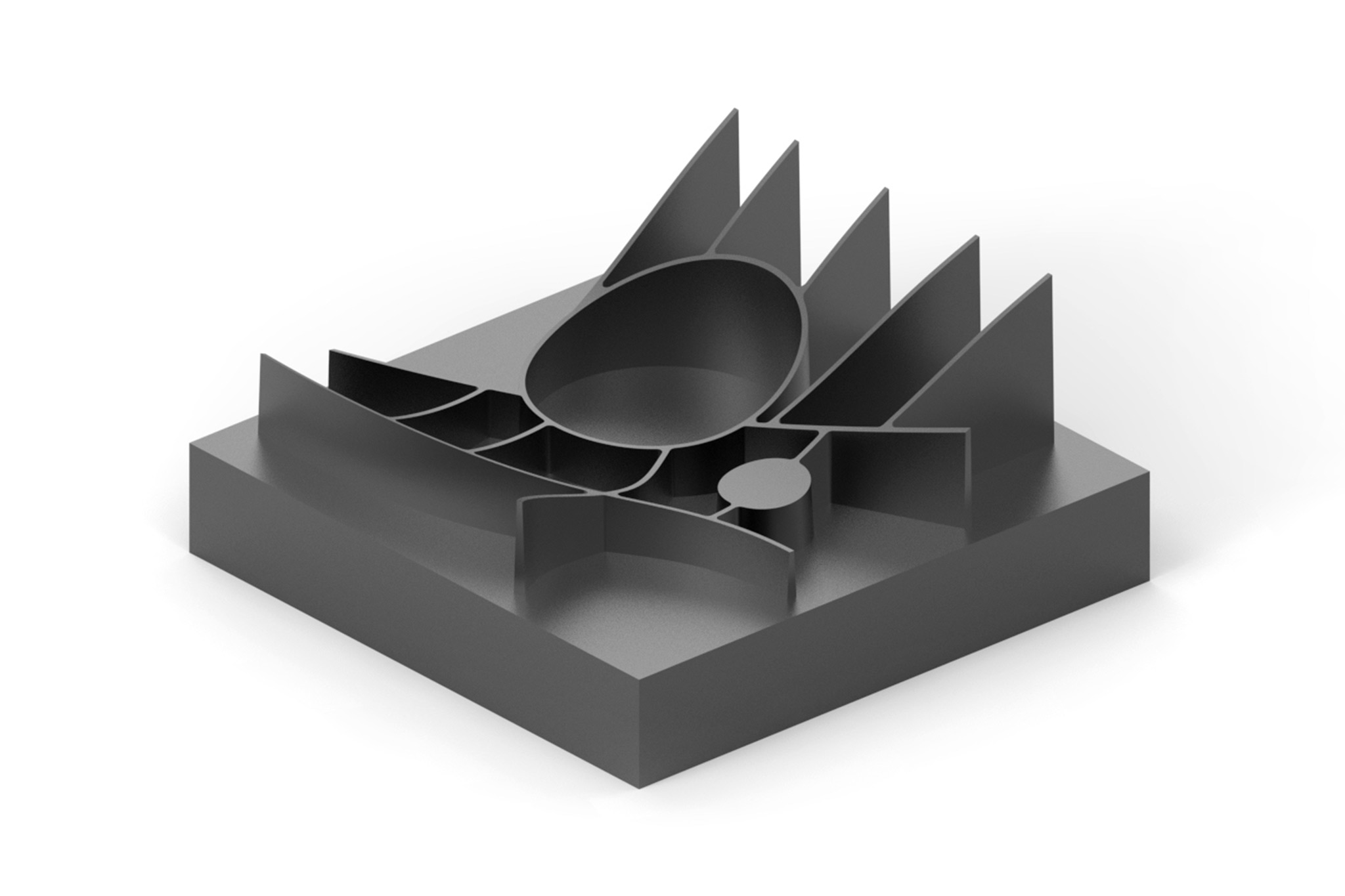

Graphit

Graphit hat eine hoch abrasive Wirkung auf das Werkzeug und erzeugt starken Verschleiß an der Schneidkante. Mit zunehmendem Verschleiß neigen die zu bearbeitenden Profile zum Ausplatzen. Daher ist ein Werkzeug mit geeigneter Geometrie und optimalem Schneidstoff Voraussetzung. Für die Bearbeitung von Graphit setzt MAPAL diamantbeschichtete Vollhartmetallwerkzeuge oder PKD-bestückte Werkzeuge ein.

Anwendungsbeispiel:

- Elektroden zum Funkenerodieren (EDM Prozesse)

Vom Roh- zum Fertigteil

-

1 / 8

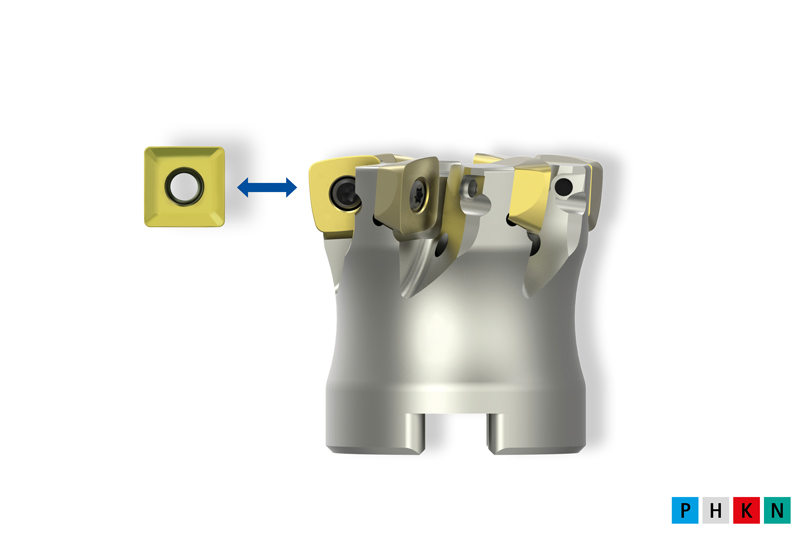

2D-Flächen

In diese Kategorie fallen einerseits direkt an der Maschine ausgeführte Bearbeitungsprozesse wie Planfräsen, Fräsen von Taschen und geraden Wänden. Andererseits auch Operationen für komplexe Geometrien, die mithilfe einer CAM-Software programmiert werden.

Zum Produktprogramm zur Bearbeitung von 2D-Flächen -

2 / 8

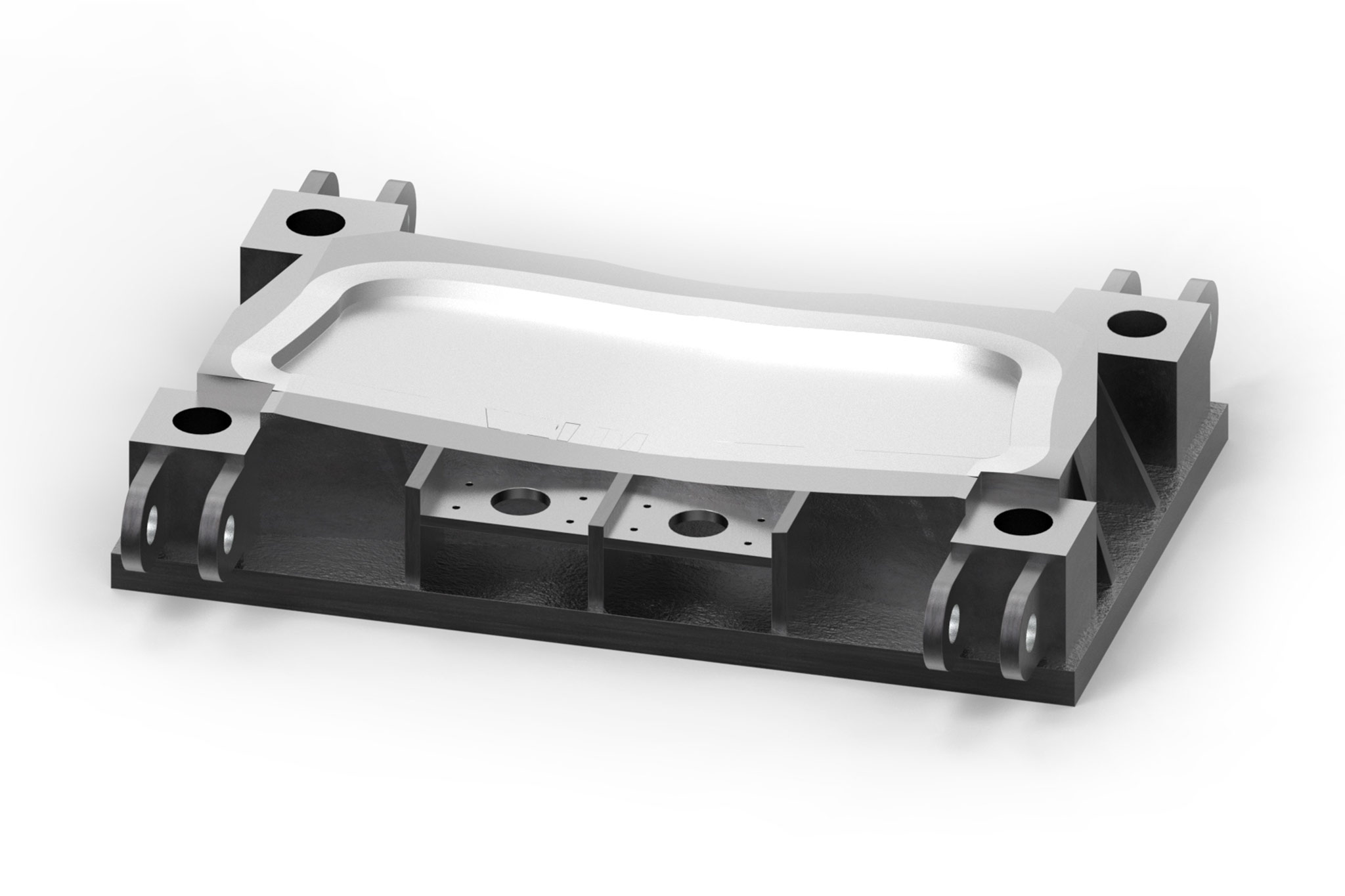

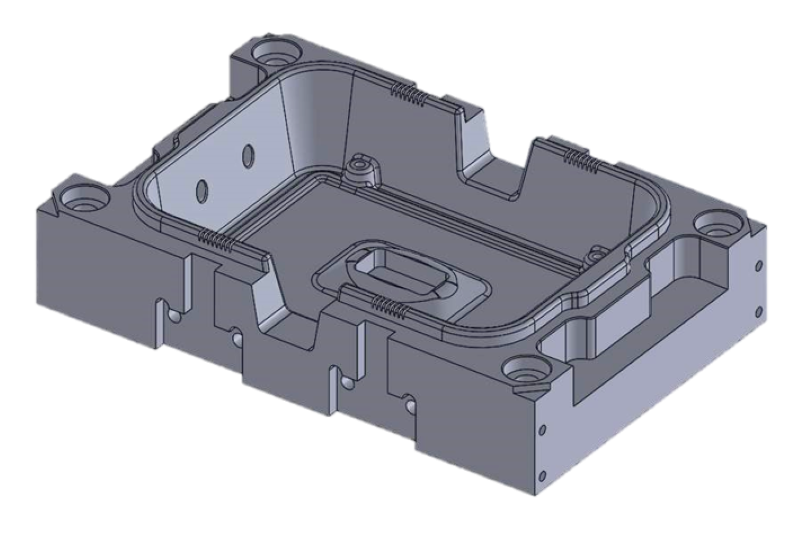

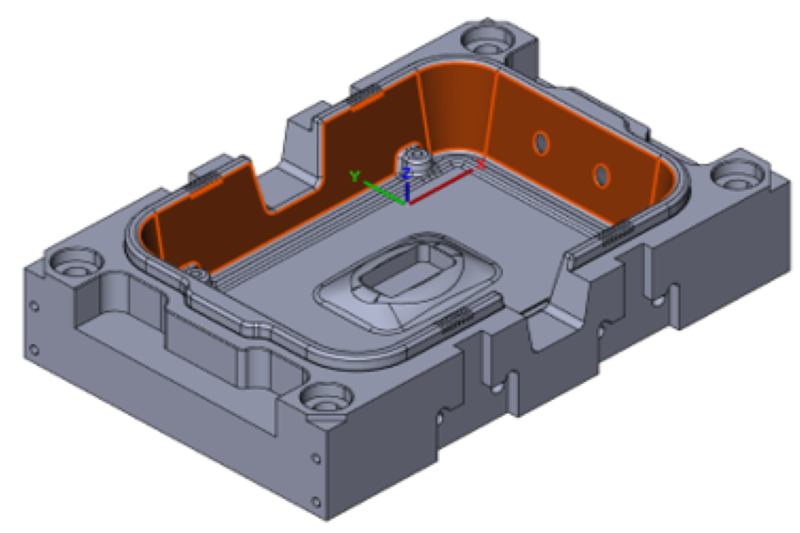

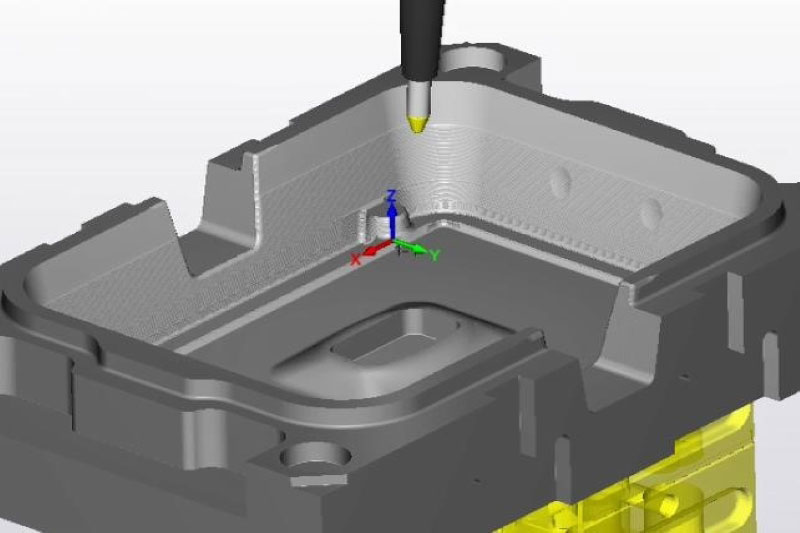

3D-Flächen

Im Werkzeug- und Formenbau ist die Herstellung komplexer werdender Formen Alltag. Kontinuierliche Weiterentwicklungen bei Werkzeugmaschinen und CAM-Software heben die Leistungsfähigkeit und Produktivität auf ein immer höheres Niveau. Somit müssen auch die eingesetzten Werkzeuge stets dem neuesten Stand der Technik entsprechen. Um hier ein Optimum zu erreichen, steht eine Prozessanalyse am Beginn der Auslegung.

Zum Produktprogramm zur Bearbeitung von 3D-Flächen -

3 / 8

Offene Taschen

Formeinsätze weisen auch Bearbeitungsaufgaben auf, die für das Gießen oder diverse Anbauteile erforderlich sind. Offene Taschen (Umfangsbearbeitungen) bearbeiten Anwender zunehmend mittels Trochoidalfräsen. Diese Bearbeitungsmethode hilft, die Bearbeitungszeiten zu optimieren und die Werkzeugstandzeiten zu verlängern.

Zum Produktprogramm zur Bearbeitung von offenen Taschen -

4 / 8

Geschlossene Taschen

Die Herstellung geschlossener Taschen erfolgt meist durch Schruppen in Z-Ebenen. Häufig wird hierbei beim Fräsen der Bearbeitungseintritt über eine Rampe gewählt. Die Wahl des Werkzeuges hängt von der Tiefe der Wände und der zu erzeugenden Ausformschräge am Bauteil ab. Das breite Portfolio von MAPAL mit modularen Systemen deckt auch die Bearbeitung tiefer Taschen mit großen Durchmessern ab.

Zum Produktprogramm zur Bearbeitung von geschlossenen Taschen -

5 / 8

Helixfräsen

Ein wesentlicher Fokus bei Fräsbearbeitungen liegt auf der Reduzierung der Bearbeitungszeit. Mit spezifischen Werkzeuggeometrien für die Bearbeitung von geschlossenen, runden Taschen gelingt es häufig, den Vorbohrprozess zu eliminieren. Beim Helixfräsen werden Fräsbahnen mit helixförmigen Eintritten programmiert, die für Taschendimensionen geeignet sind.

Zum Produktprogramm Helixfräsen -

6 / 8

Ebene Flächen

Operationen zur Erzeugung von ebenen Flächen kommen sehr häufig und in unterschiedlichen Bereichen im Werkzeug- und Formenbau vor: Sei es bauteilbedingt, strategiebedingt durch die jeweilige Fräsbearbeitung oder durch Anforderungen bei Formschließflächen sowie Abschnitten und Stanzformen. Die Auswahl des passenden Werkzeuges erfolgt dann in Abhängigkeit von Anwendung und Anforderung.

Zum Produktprogramm zur Bearbeitung von ebenen Flächen

-

7 / 8

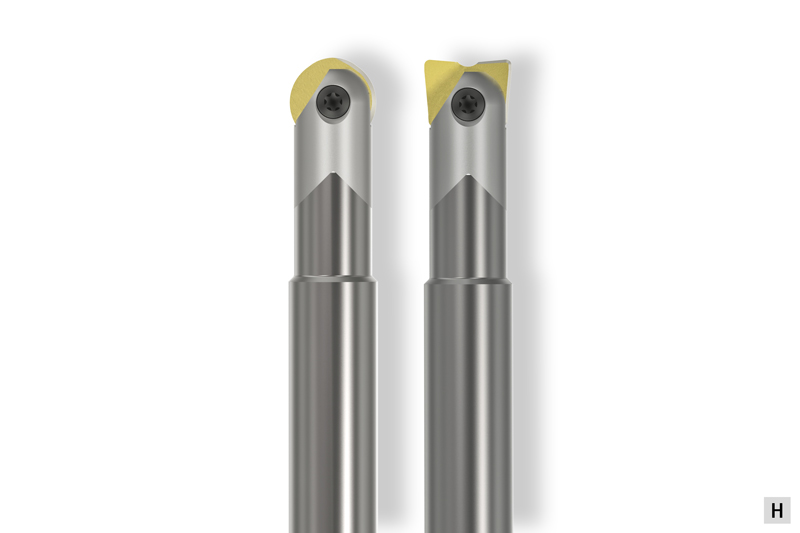

Dünne Wandungen und Rippen

Kunststoff-Spritzgussformen und Druckgussformen weisen häufig Rippen und dünne Wandungen auf. Rippen zum Beispiel werden zunehmend gefräst, da dieses Verfahren kostengünstiger ist als das EDM-Verfahren (Funkenerodieren). Zur Anwendung kommen in der Regel lange beziehungsweise überlange Hartmetallwerkzeuge mit kleinen Durchmessern. Auch sind hier kundenspezifische Lösungen (RibCutter) passend zur jeweiligen Rippenform möglich.

Zum Produktprogramm zur Bearbeitung von dünnen Wandungen und Rippen -

8 / 8

Kleine und große Bohrungen

Im Werkzeug- und Formenbau gibt es eine große Bandbreite an Vollbohroperationen: Von großen Bohrungen für Führungssäulen über tiefe Bohrungen für das Kühlsystem bis hin zu hochpräzisen Bohrungen für Auswerferstifte. Für die einzelnen Fertigungsschritte bietet MAPAL ein umfassendes Portfolio an Bohr- und Reibwerkzeugen.

Zum Produktprogramm zur Bearbeitung von kleinen und großen Bohrungen

Alles aus einer Hand

Engineering Workflow - Von der Theorie zur Praxis

Further items about the die&mould area

-

02.12.2025

Großes Werkzeugpaket für Zerspanungstechnik Mangner GmbH

MAPAL hat die Zerspanungstechnik Mangner GmbH mit einem großen Werkzeugpaket im Bereich Bohren ausgestattet

-

04.03.2025

CORMOL relies on milling cutters such as the OptiMill-3D-HF from MAPAL for tool making

CORMOL from Portugal manufactures stamping tools, for which it has been working closely with MAPAL since 2022. With the OptiMill-3D-HF, CORMOL has found a reliable and economical tool solution.

#Products #Industries #CaseStudies #Technology #Die&Mould #Milling

-

25.06.2024

Efficient production in die and mould making: Krämer+Grebe and MAPAL

The mouldmaking company Krämer+Grebe optimises production with MAPAL reamers and milling cutters and ensures process reliability in international competition.

#CaseStudies #Products #Industries #Reaming&FineBoring #Milling #Die&Mould

Our retail partners

Responsibility according to postcode areas

-

1 / 16

Postcode 35

FRITZ WEG GmbH & Co. KG

Ahornweg 41

35713 Eschenburg-WissenbachPhone: +49 2774 701-0

Fax: +49 2774 701-39

Email: info@fritzweg.de

Web: www.fritzweg.de -

2 / 16

Postcode 44

Jansen Schneidwerkzeuge Vertriebs GmbH

Im Käsebrink 12

58840 PlettenbergPhone: +49 2391 9177-0

Fax: +49 2391 9177-20

Email: info@j-s-v.com

Web: www.j-s-v.com -

3 / 16

Postcode 51

Jansen Schneidwerkzeuge Vertriebs GmbH

Im Käsebrink 12

58840 PlettenbergPhone: +49 2391 9177-0

Fax: +49 2391 9177-20

Email: info@j-s-v.com

Web: www.j-s-v.com -

4 / 16

Postcode 56, 57

FRITZ WEG GmbH & Co. KG

Ahornweg 41

35713 Eschenburg-WissenbachPhone: +49 2774 701-0

Fax: +49 2774 701-39

Email: info@fritzweg.de

Web: www.fritzweg.de -

5 / 16

-

6 / 16

Heinrich Meier GmbH

Herrenwaag 31

75417 MühlackerPhone: +49 7041 9530-0

Fax: +49 7041 9530-30

Email: info@heinrich-meier.de

Web: www.heinrich-meier.de -

7 / 16

Postcode 63 - 69

Heinrich Meier GmbH

Herrenwaag 31

75417 MühlackerPhone: +49 7041 9530-0

Fax: +49 7041 9530-30

Email: info@heinrich-meier.de

Web: www.heinrich-meier.de -

8 / 16

Postcode 70 - 73

Dieter Schätzle GmbH & Co. KG

Präzisionswerkzeuge

Unter Haßlen 12

78532 TuttlingenPhone: +49 7462 9465-0

Fax: +49 7462 9465-50

Email: info@schaetzle-werkzeuge.de

Web: www.schaetzle-werkzeuge.de -

9 / 16

Postcode 74, 75

Heinrich Meier GmbH

Herrenwaag 31

75417 MühlackerPhone: +49 7041 9530-0

Fax: +49 7041 9530-30

Email: info@heinrich-meier.de

Web: www.heinrich-meier.de -

10 / 16

Postcode 76 - 79

Dieter Schätzle GmbH & Co. KG

Präzisionswerkzeuge

Unter Haßlen 12

78532 TuttlingenPhone: +49 7462 9465-0

Fax: +49 7462 9465-50

Email: info@schaetzle-werkzeuge.de

Web: www.schaetzle-werkzeuge.de -

11 / 16

Postcode 80 - 87

AB1-Tools e.K.

Goethering 45

91732 MerkendorfPhone: +49 9826 333-2241

Fax: +49 9826 333-3691

Email: info@ab1-tools.com

Web: www.ab1-tools.com -

12 / 16

Postcode 88, 89

Dieter Schätzle GmbH & Co. KG

Präzisionswerkzeuge

Unter Haßlen 12

78532 TuttlingenPhone: +49 7462 9465-0

Fax: +49 7462 9465-50

Email: info@schaetzle-werkzeuge.de

Web: www.schaetzle-werkzeuge.de -

13 / 16

Postcode 90 - 97

AB1-Tools e.K.

Goethering 45

91732 MerkendorfPhone: +49 9826 333-2241

Fax: +49 9826 333-3691

Email: info@ab1-tools.com

Web: www.ab1-tools.com -

14 / 16

Danmark

EDECO TOOL APS

Naverland 2

2600 Glostrup

DanmarkPhone: +45 7060 2029

Email: info@edeco.dk

Web: www.edeco.dk -

15 / 16

Italy

TEKNOS S.r.l.

Via A. Pigafetta, 2

35011 Campodarsego (PD)

ItaliaPhone: +39 049 8877061

Email: info@teknositalia.it

Web: www.teknositalia.it -

16 / 16

Portugal

Álamo-Ferramentas Unipessoal Lda

Rua da ETAR, Lote 9

Zona Industrial de Oiã

3770-059 Oiã

Phone: +351 234 728-193

Email: geral@alamo-ferramentas.com