28.08.2023

Sustainability at various levels

Modern technologies, self-generated energy and climate-friendly mobility. MAPAL is investing four million euros in its headquarters in Aalen alone.

MAPAL puts a premium on energy and environmental management. The aim is to make the operational processes at all the Group’s sites more sustainable. MAPAL has already proactively implemented a series of measures in recent years. Other projects are ready to be realized. By 2025, the company wants to reduce the energy-related CO2 emissions of its products by 40 percent compared to 2015.

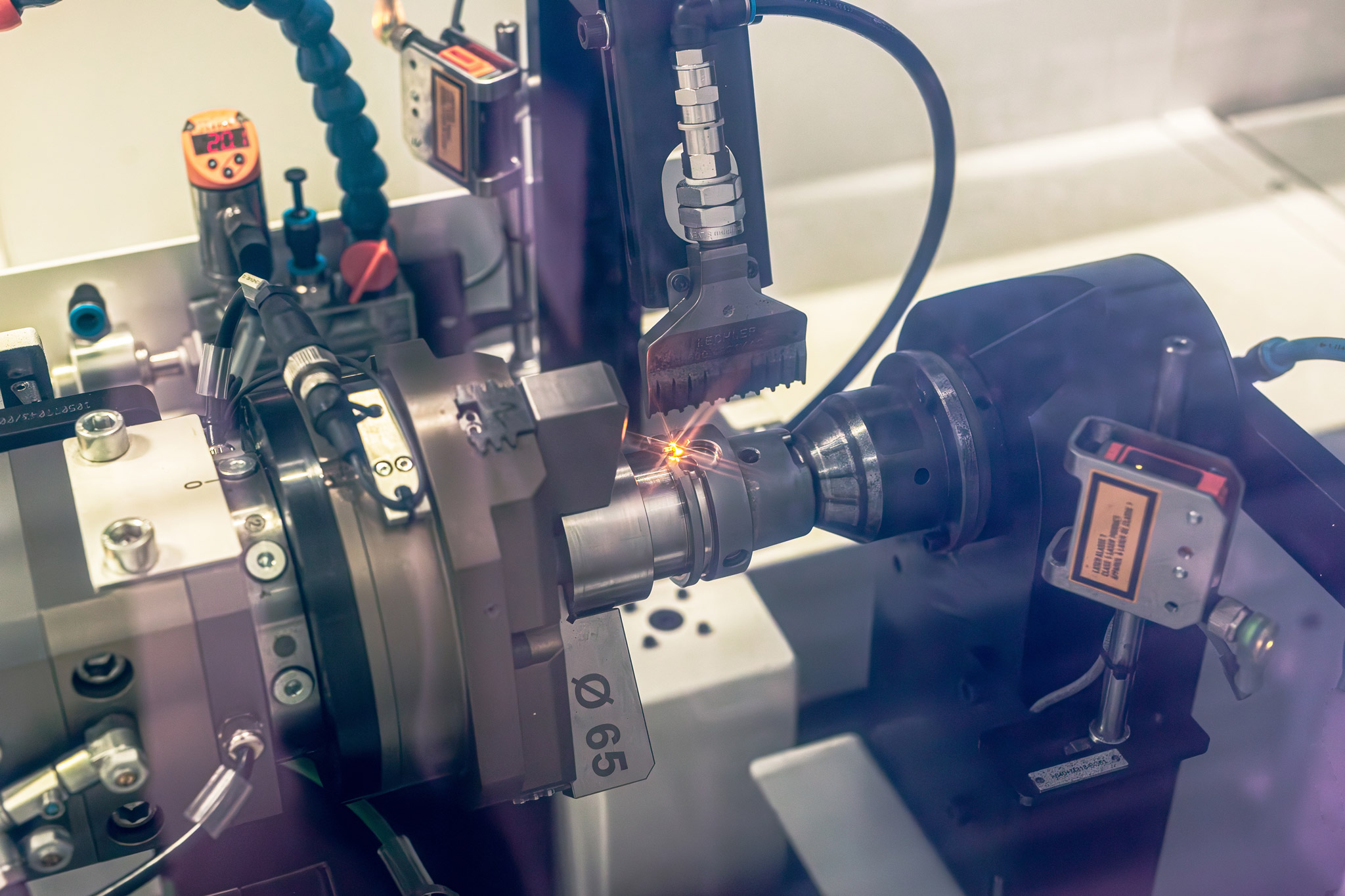

Use of smart technologies

Production of electricity

Green power and green heat

The company’s main plant in Aalen is consistently moving towards environmentally-friendly energy supply. A highly efficient cogeneration unit was in operation for many years. In the spring of last year, it has been replaced by a new even more efficient unit. As a result, MAPAL saves around 80 tons of CO2 every year. In addition, the company uses the waste heat from the machines in the newer halls to heat the buildings. Another hall at the Aalen plant will soon get a heat-recovery system and a high-performance heat pump to further improve the sustainable use of heating energy.

Since 2021, MAPAL has only purchased electricity produced in an environmentally friendly manner to meet its electricity needs both in the main plant in Aalen and in the eight subsidiaries in Germany. The main plant in Aalen will soon produce a large part of this itself. The installation of PV systems on several hall roofs is already in the final stages of planning. It will allow MAPAL to produce around half a million kilowatt hours of electricity to meet its own demand.

Climate-friendly mobility

MAPAL is also investing in a green future in the field of mobility. The company fleet consists of an increasingly number of electric and hybrid cars. Six electric charging stations are available in the visitors’ car park at the Aalen plant to provide a charging facility for visitors’ and company vehicles. All German sites now have their own charging stations. There are plans to extend this further. The installation of the first charging points for employees in Aalen together with the creation of a solar carport in the car parks is already underway. In the medium term, the company wants to generate a further 500,000 kilowatt hours of electricity in this way, i.e., a total of around one million kilowatt hours of electricity. The current investments in sustainable projects at the Aalen site alone thus add up to around four million euros.

This includes the environmentally friendly mobility of employees, such as providing company bikes, subsidising the “Deutschland-Ticket” and the option to work remotely. Converting lighting to LED technology and switching product packaging to recycled materials are also part of MAPAL’s sustainability concept.

Clear commitment to sustainable corporate culture

Contact

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Phone: +49 7361 585 3342