15.07.2025

MAPAL at EMO 2025

75 Years of MAPAL – Shaping the Future with Partnership, Productivity and Precision

The EMO is the perfect platform for MAPAL to showcase new solutions, nurture ties and establish partnerships. Personal interaction with existing and new customers at trade fairs is a key part of the precision tool manufacturer’s company philosophy and remains firmly rooted in its marketing strategy. “The EMO is not just a trade fair for us – it plays a key role in our customer relationships and is the venue where we unveil our product innovations for the coming year”, explains Jacek Kruszynski, Chief Technology Officer at MAPAL.

MAPAL is presenting its latest solutions and innovations at stand A20 in Hall 4. Both MAPAL and the EMO are celebrating milestone anniversaries this year, with MAPAL turning 75 and the EMO turning 50.

Enhancing productivity in customer processes is the guiding principle of the trade fair appearance and 2026 innovations

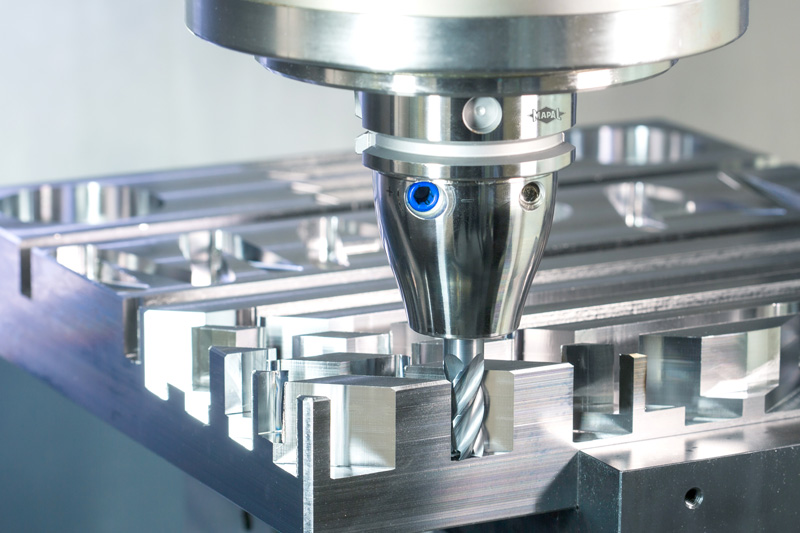

OptiMill-Uni-HPC: New standards in process reliability for milling

Productivity gains when machining large diameters with the HPR400 reaming system

MAPAL’s HPR400 reaming system offers a variety of advantages in terms of machining speed, ease of handling and flexibility for machining large diameters. MAPAL is showcasing several new solutions at the EMO in order to enhance productivity in series production.

The combination tool with the ISO leading stage and HPR400 system is an innovative one-shot solution for finish machining with high material removal. It enables bores to be made with up to 6 mm of stock removal in a single working step, thus ensuring minimum cycle times.

The HPR400 plus series was specifically developed for machining face grooves. The new tool concept significantly improves the cost effectiveness of machining bores with special base contours.

Together with a new tool solution for finishing stator bores in electric motors, the newly developed solutions are very good examples of how cost-effectiveness in machining can be increased even when there are complex requirements.

“Empower Your Aluminium Machining”

75 years of MAPAL: From a small tool manufacturer to global manufacturing expert

Contact

Mathias Ostertag Public Relations mathias.ostertag@mapal.com Phone: +49 7361 585 3566