少量生産 – コンビネーションツールによる工具交換の削減

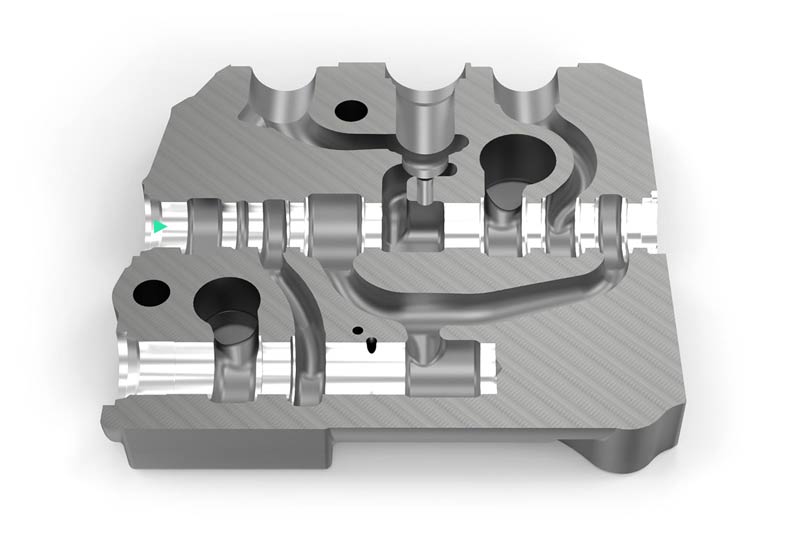

バルブケース FCD-300 - スプール穴

お客様の初期の加工状況

- 少量生産

- ツール調整機能あり

- 過度なツール交換

- 高い機械稼働率

- 次工程のワンパスホーニングによる高い費用の発生

ソリューションの特徴

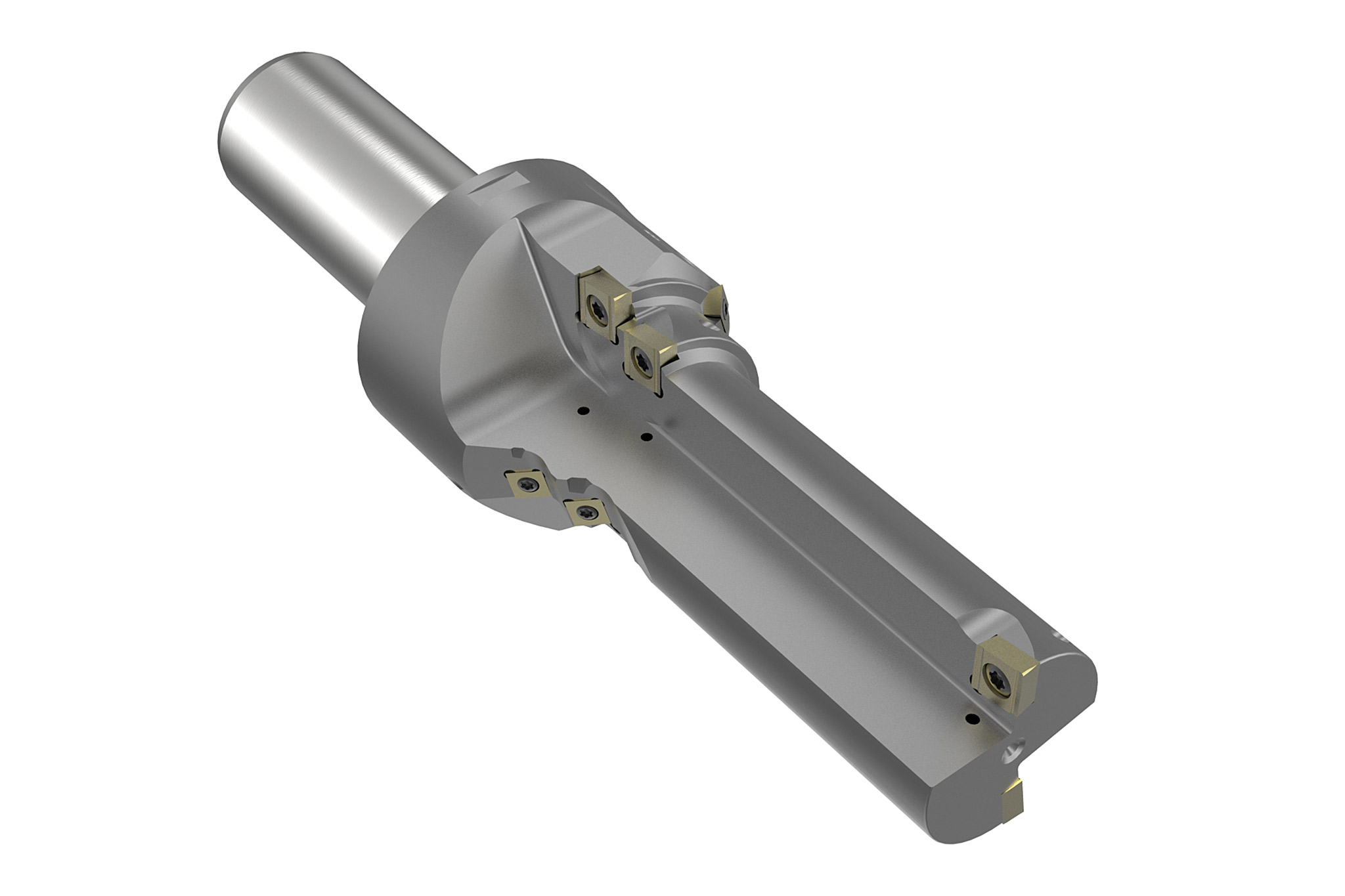

- インサート付き多段式ガンボーリング工具の採用により、工具交換回数を削減

- 形状をワンショットで完成

- ファインボーリングツールは、最高の加工穴品質を実現し、両側からの基準となる前加工穴のアライメント誤差の補正が可能

スプール穴

1. パイロット穴加工とボーリング

- ラジアルおよびタンジェンシャルインサート付き多段式ガンボーリング工具

- スプール穴の前加工と形状の仕上げを一度に行うことが可能

2. コントロールエッジ加工

- 超硬ソリッドプロファイルツール

- 高い精度と品質のコントロールエッジ加工を実現

- 破損のないコントロールエッジ

3. ファインボーリング加工

- 調整可能なインサートとガイドパッド付きファインボーリングツール

- 超精密・長尺ボアのバー加工に最適

![ANNUAL PRODUCTION COSTS OF THE COMPENSATOR BORE [€]](/medias/sys_master/root/h31/h1c/9043461046302/Grafiken_EN-14/Grafiken-EN-14.jpg)

利点

- 交換可能な標準インサート付き多段式ガンボーリング工具、コントロールエッジ加工、ファインボーリングによる最適な加工プロセス

- 高い精度と工程信頼性

- ホーニング加工の手間を省き、コスト削減を実現