Fittings

Anwendungslösungen durch Aussteuertechnologie

Fittings aus CuSi4Zn9MnP

Ausgangssituation beim Kunden

- Bearbeitung auf Rundtaktmaschine

- Anforderung: Geringe Taktzeit und höchste Produktivität im Großserienprozess

- Werkzeugsystem muss außerhalb der Maschine voreingestellt und flexibel an Bauteilvarianten angepasst werden können

Besonderheiten der Lösung

- Aufsatzwerkzeuge mit Adapter voreinstellbar ohne Maschinenstillstand

- VTS-Schnittstelle

- Schneller und einfacher Wechsel der Aufsatzwerkzeug

- Keine Falschmontage-/Positionierung beim Aufsatzwerkzeugwechsel möglich

- Wendeschneidplattentechnologie für geringe Schneidstoffkosten

- PKD-Schneidstoffe garantieren höchste Wirtschaftlichkeit im Serienprozess

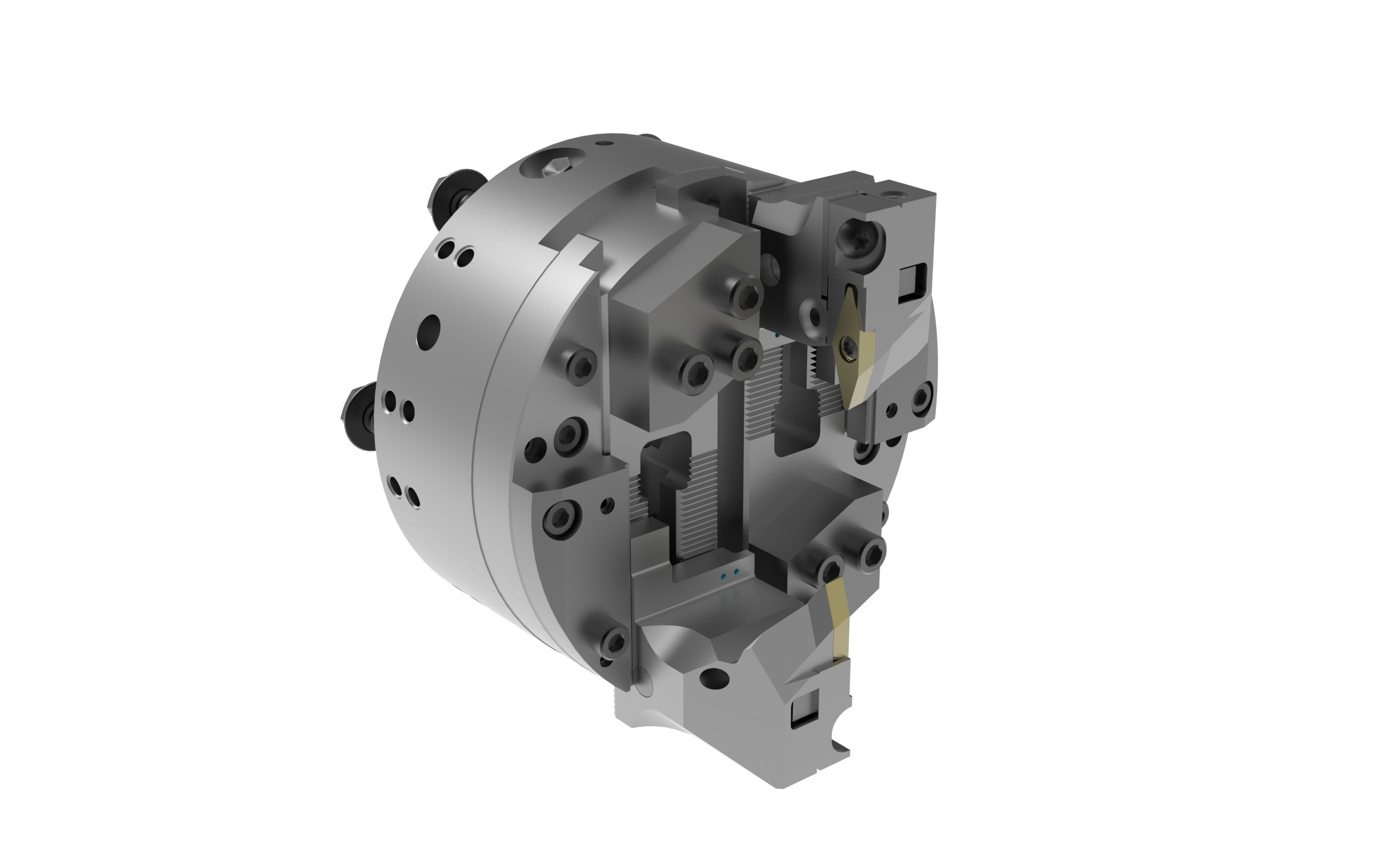

Werkzeughighlights

- VTS-Schnittstelle für schnellen und einfachen Wechsel der Aufsatzwerkzeuge

- Doppelschieber z=2 für geringe Taktzeiten und vollständigem Unwuchtausgleich

- Optimale Kühlmittelzufuhr direkt über das Aufsatzwerkzeug

![CYCLE TIMES [MIN.]](/medias/sys_master/root/h89/h13/9687965761566/DE__Diagramme4/DE-Diagramme4.jpg)

Vorteile

- Höchste Produktivität, da alle Bearbeitungsaufgaben (Konturen, Gewinde...) durch MAPAL Aussteuertechnologie effizient erledigt werden können

- Signifikante Taktzeitreduzierung um 35% durch zweischneidige Werkzeuglösungen

- Reduzierung der Stillstandzeiten bei Produkt- und Schneidenwechsel im Serienprozess durch VTS-Schnittstelle

- Nur ein Plandrehkopf-Typ mit wechselbaren Aufsatzwerkzeugen für gesamte Produktpalette notwendig

- Maximale Flexibilität in Hinsicht auf REACH-Verordnung und dadurch wechselnde Bauteilanforderungen