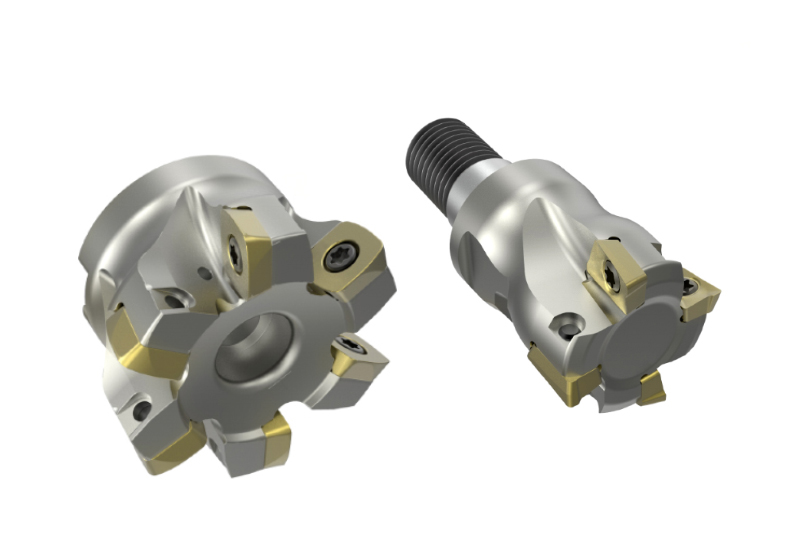

粗旋削

加工量の大半を占めるのが粗旋削加工です。高送り加工やトロコイドミリング加工などの特殊な加工方法により、加工時間を短縮し、経済性を高めることができます。交換可能な切削インサート付きツールや超硬ソリッドエンドミルに加え、特殊な粗削り形状を持つ高性能ミリングカッターも使用されます。

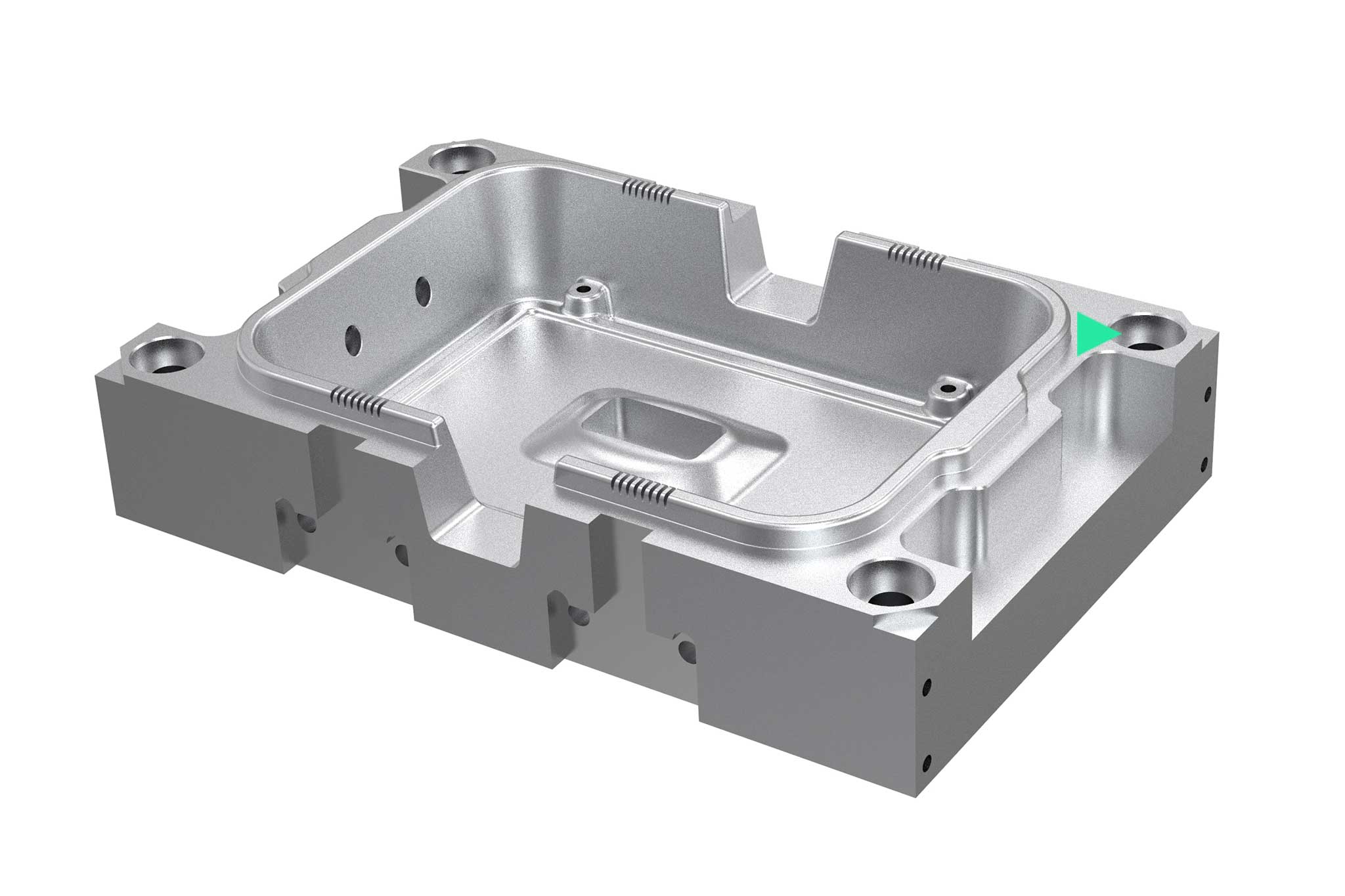

残材の粗旋削

粗旋削後、特にコーナー部やキャビティ部の残材を、二次加工でできるだけ一定の取り代になるように事前に機械加工します。通常、コーナーRのあるツールまたは高送りミリングカッターが使用されます。必要に応じて、球面シートカッターでコーナー部の残材を除去することも可能です。

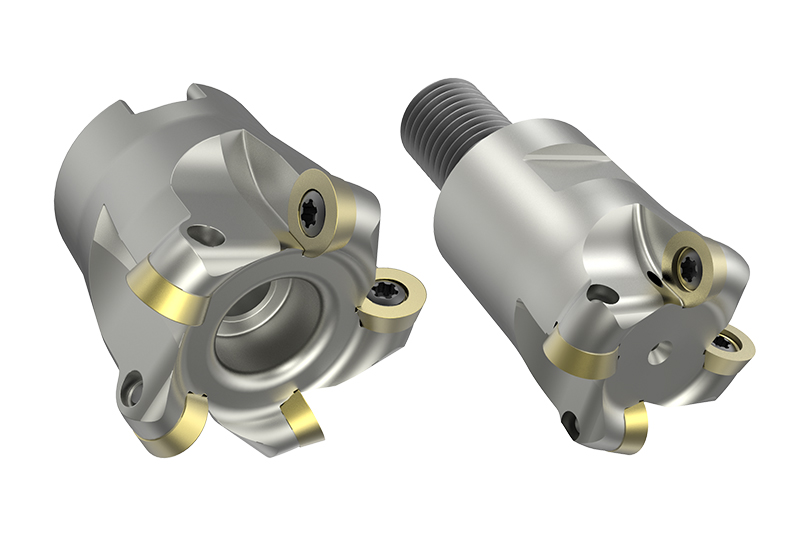

中仕上げ

寸法精度や表面品質への要求が高い場合は、仕上げ前に中仕上げを行うことをお勧めします。中仕上げは、加工工程を最終的な形状プロファイルに近づけるものです。表面品質への要求が高い高速仕上げを可能にするため、できるだけ一定の残材を得ることを目的としています。粗旋削後の取り代は、高硬度材で約0.5~1mm、軟質材で0.03~0.5mmです。中仕上げ後の一定寸法は、高硬度材で0.05~0.1mm、軟質材で0.1~0.3mmです。

仕上げ

仕上げでは、残った取り代を取り除き、最終的な形状に仕上げます。中仕上げ後の寸法は、高硬度材で0.05~0.1mm、軟質材で0.1~0.3mmです。最終的な被削材質の輪郭に応じて、球面シートカッターおよびコーナーRミリングカッターを選択します。