Produzione di piccole e medie serie con utensili non registrabili

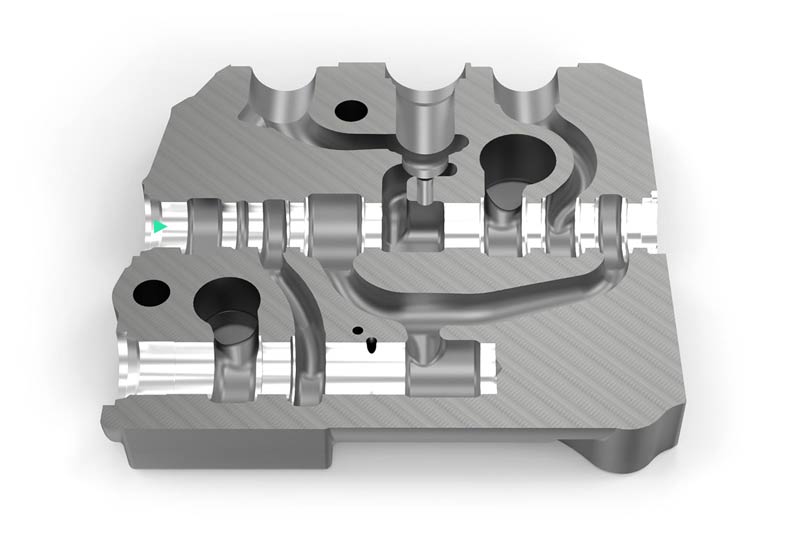

Corpo valvola EN-GJS-400-15 – Foro cursore

Situazione di partenza del cliente

- Ordini individuali, piccole e medie quantità

- Nessuna possibilità di registrazione utensile

- Lead time ridotto richiesto

- Elevati costi orari della macchina

- Disponibilità di un processo di levigatura a espansione stabile

- Progettazione utensile adattata a diverse varianti di componenti

Particolarità della soluzione

- Nessuna formazione di anelli grazie alla speciale geometria di barenatura → Eliminazione dei costi per la rimozione degli anelli

- Ottimi risultati di prelavorazione grazie a un processo calibrato di foratura pilota e di barenatura → Supporto alesatore nel foro pilota = linearità ideale, posizione

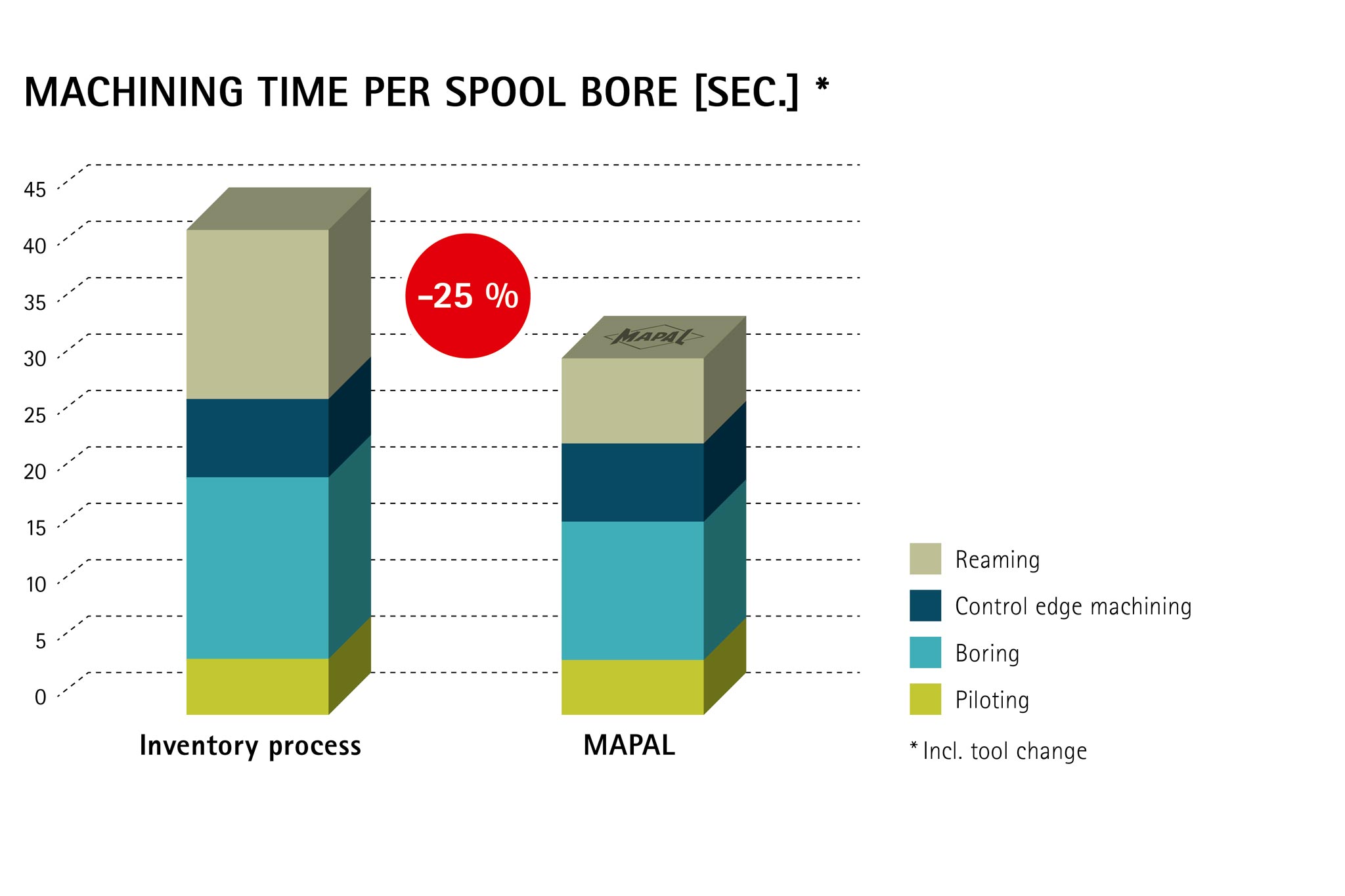

- Elevata produttività con una perfetta qualità di prelavorazione → Elevati parametri di taglio – Riduzione del tempo di lavorazione

Foro cursore

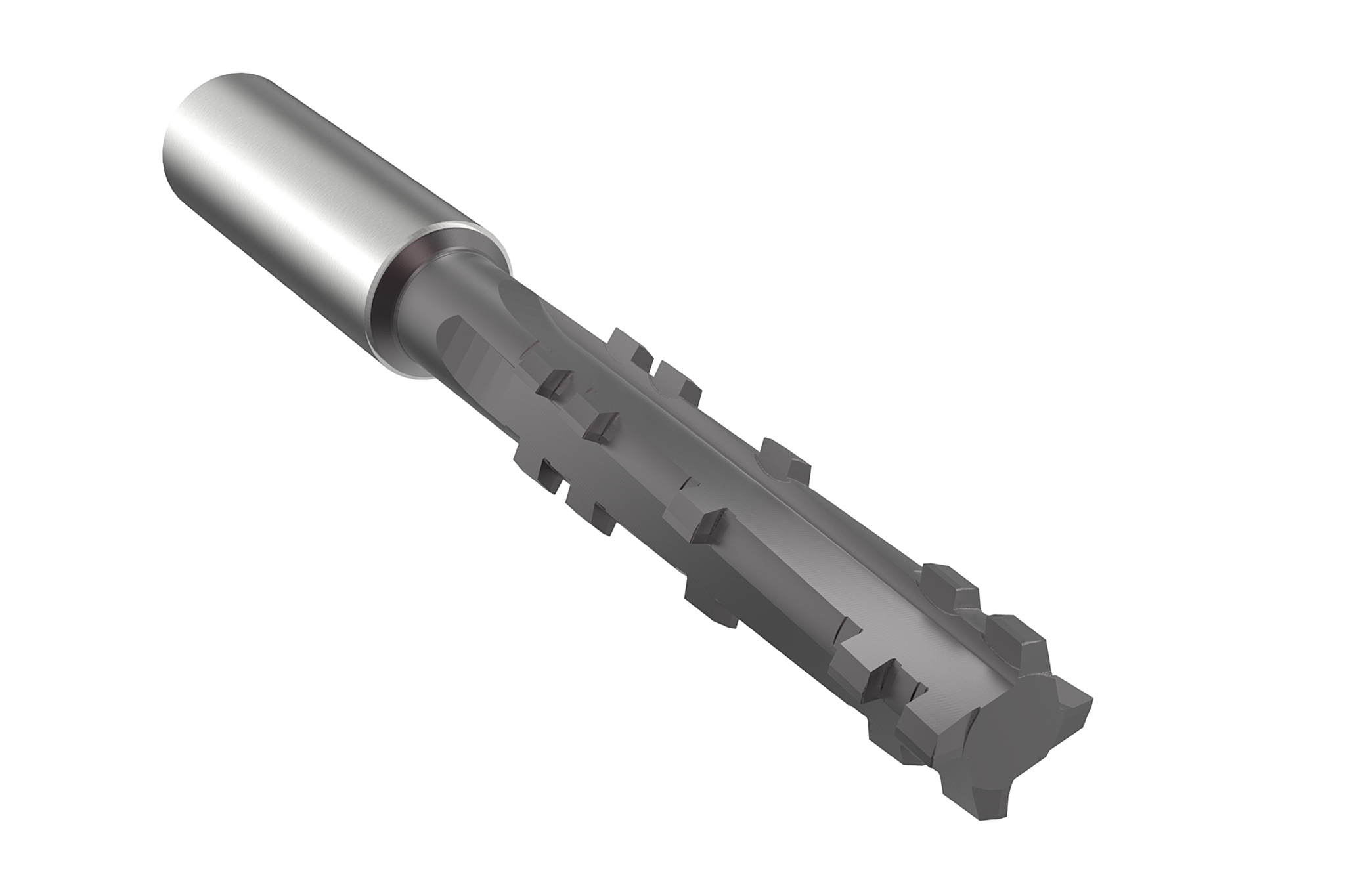

1. Foratura pilota

- Bareno in metallo duro integrale dotato di sei margini di guida per circolarità e linearità perfette

- Ottimo flusso di trucioli e ampie possibilità di riaffilatura grazie alla tecnologia multi-fase e a un’idonea adduzione del refrigerante

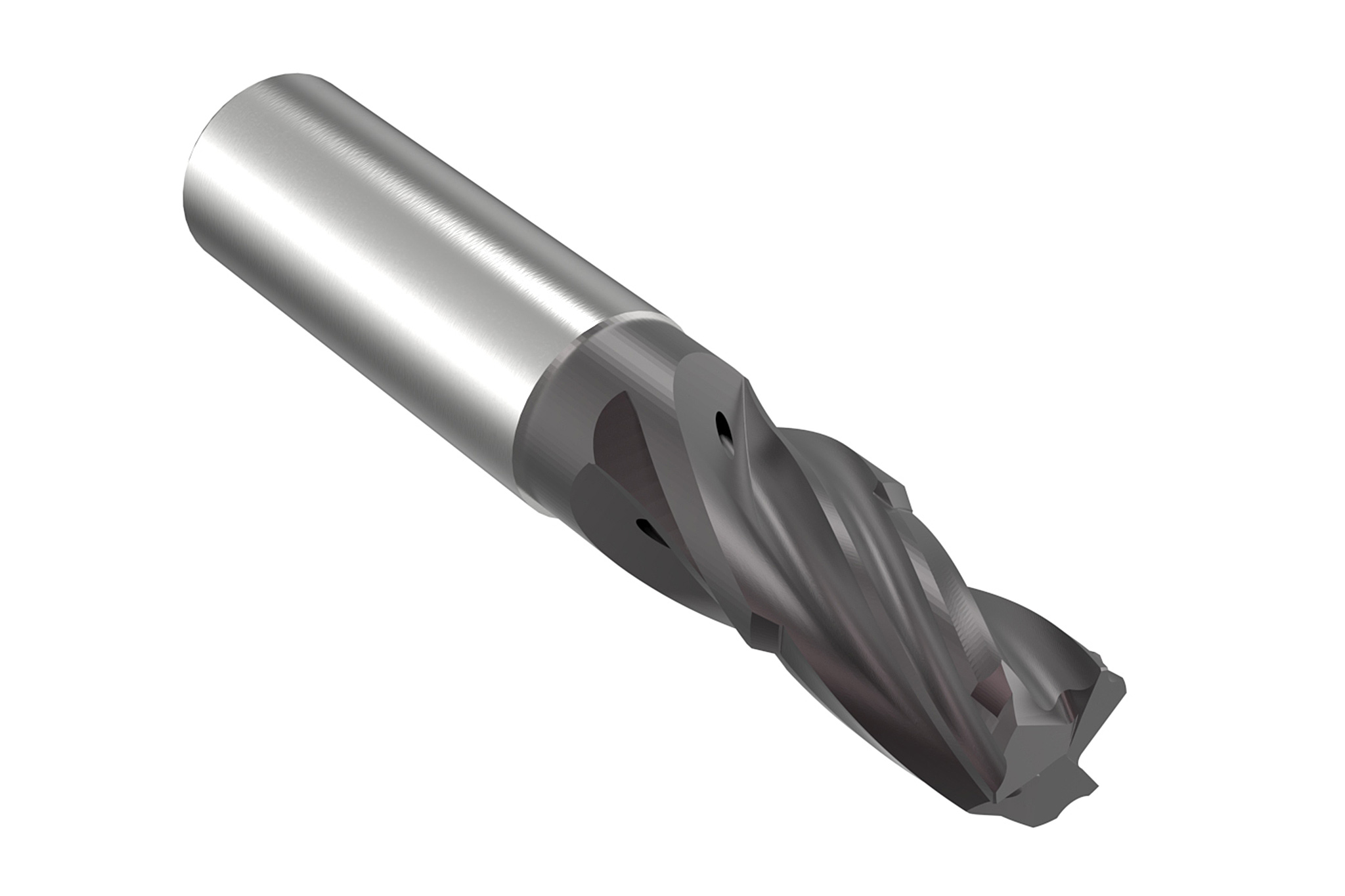

2. Barenatura

- Bareno in metallo duro integrale dotato di tre taglienti, sei margini di guida e una speciale geometria di taglio

- Foro dritto, flusso di trucioli ideale e guida su tutta la lunghezza del foro

3. Lavorazione delle gole

- Risparmio notevole sui tempi di ciclo grazie alle speciali frese circolari in metallo duro integrale

- Spigoli all’interno del foro cursore definiti senza interruzioni

4. Alesatura

- Alesatori a più taglienti per elevati parametri di lavorazione

- Perfetto controllo dei trucioli grazie all'elica a sinistra e all’ottima adduzione del refrigerante

Vantaggi

- Investimento ridotto

- Lead time ridotto

- Elevata disponibilità del centro di lavorazione

- Costi di produzione ridotti

- Registrazione utensile non necessaria

- Possibilità di riaffilatura in tutto il mondo