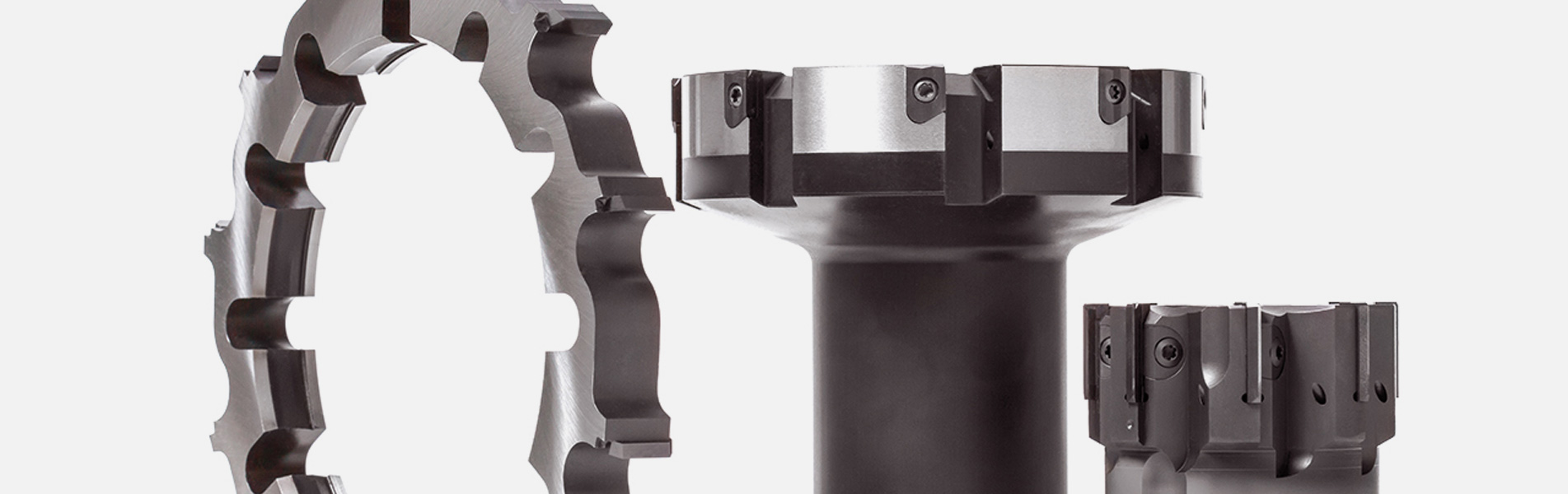

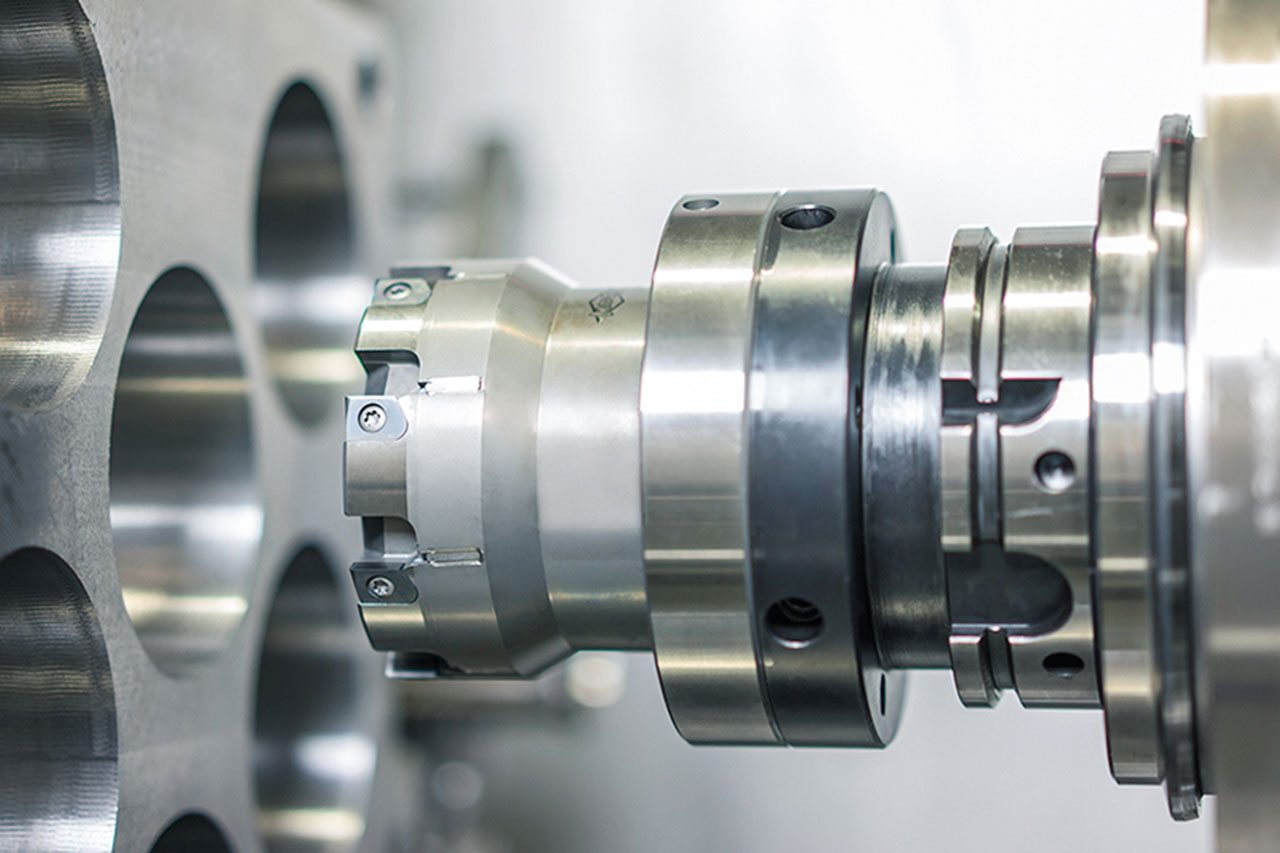

大径穴加工用マルチブレードハイパフォーマンスリーマ

大径穴を調整された公差内で仕上げ加工する際、ユーザーはしばしば次のような疑問に直面します。リーマ加工かボーリング仕上げ加工か?特に直径40mmを超える加工に合わせた、個々の構成オプションとHSKあるいはモジュールシャンクを備えた高性能リーマのプログラムです。ホルダー付きの単純なカッターリングから現場での簡単な刃交換ができる高性能ツールまで、マパールはすべての用途において、ほぼすべての材料の高精度でコスト効率の高い加工のために最適なソリューションを提供します。

HPR400 plus

Aucun réglage et quatre arêtes de coupe nette réduction des coûts unitaires

Le développement des alésoirs HPR400 a été axé sur une meilleure rentabilité par un reconditionnement efficace. Ces outils multicoupe séduisent par leur performance, les conditions de coupe optimisées et le client peut remplacer lui-même aisément des plaquettes de coupe sur place. Cela logement est possible parce qu’ils sont dotés de porte-plaquettes de grande précision. Les coûts logistiques liés au transport vers le fabricant sont donc entièrement supprimés. Le nombre d’outils en circulation et les frais de reconditionnement se stabilisent à un faible niveau.

Afin de rendre encore plus rentable l’usinage de grands diamètres, les plaquettes du nouvel HPR400 plus ne sont plus conçues sous forme d’outil monocoupe mais elles sont équipées de quatre arêtes de coupe. Le matériau de coupe est ainsi parfaitement utilisé. La production MAPAL à haut niveau technologique garantit que les plaquettes amovibles à quatre arêtes de coupe fabriquées avec la plus grande précision peuvent être facilement retournées ou remplacées sur place par un employé du client. Celui-ci peut donc disposer du stock optimal d’arêtes de coupe, ce qui diminue les frais de reconditionnement et les coûts unitaires.

HPR400

Remplacement des plaquettes de coupe sur place aisé

La série HPR400 étant dotée de porte-plaquettes spéciaux de grande précision, il suffit d’une clé dynamométrique pour changer soimême sur place les arêtes de coupe. Tout montage erroné est exclus car il n’y a qu’une seule position de montage et les plaquettes de coupe peuvent être montées partout. Plus aucun réglage ni de reconditionnement. Les clients ont uniquement besoin d’avoir les arêtes de coupe MAPAL en stock. La quantité d’outils est moindre car tout reconditionnement du corps est inutile. Avec l’alésoir HPR400, le client obtient ainsi aisément des perçages de très grande précision et peu d’outils sont en circulation.

HPR300

Moins de frais grâce au reconditionnement innovant

Avec la gamme HPR300, MAPAL propose un système dont les outils fixes peuvent être rééquipés et revêtus sensiblement plus vite et de manière nettement plus rentable. Les plaquettes de coupe brutes sont bloquées de manière fiable dans l’outil via des griffes. Les diamètres et entrées sont ensuite polies avec la plus grande précision. En cas de reconditionnement après la fin de la durée de vie, les arêtes émoussées peuvent être remplacées par de nouvelles, facilement et rapidement, et polies au μ près en qualité d’origine.Le fait que le corps et notamment la queue de serrage gardent leur précision élevée initiale est un autre avantage décisif du système HPR300. Au moment de remplacer les arêtes, le corps de l’outil n’est soumis à aucune sollicitation thermique et tout nettoyage complexe est inutile. En moyenne, il est possible de reconditionner les outils jusqu’à quatre fois tandis que les alésoirs HPR300 peuvent être rééquipés au moins dix fois. Les outils sont ainsi amortis dès les premiers reconditionnements et apportent tout au long de leur durée de vie de nettes économies sans compromettre la performance par rapport aux outils brasés.