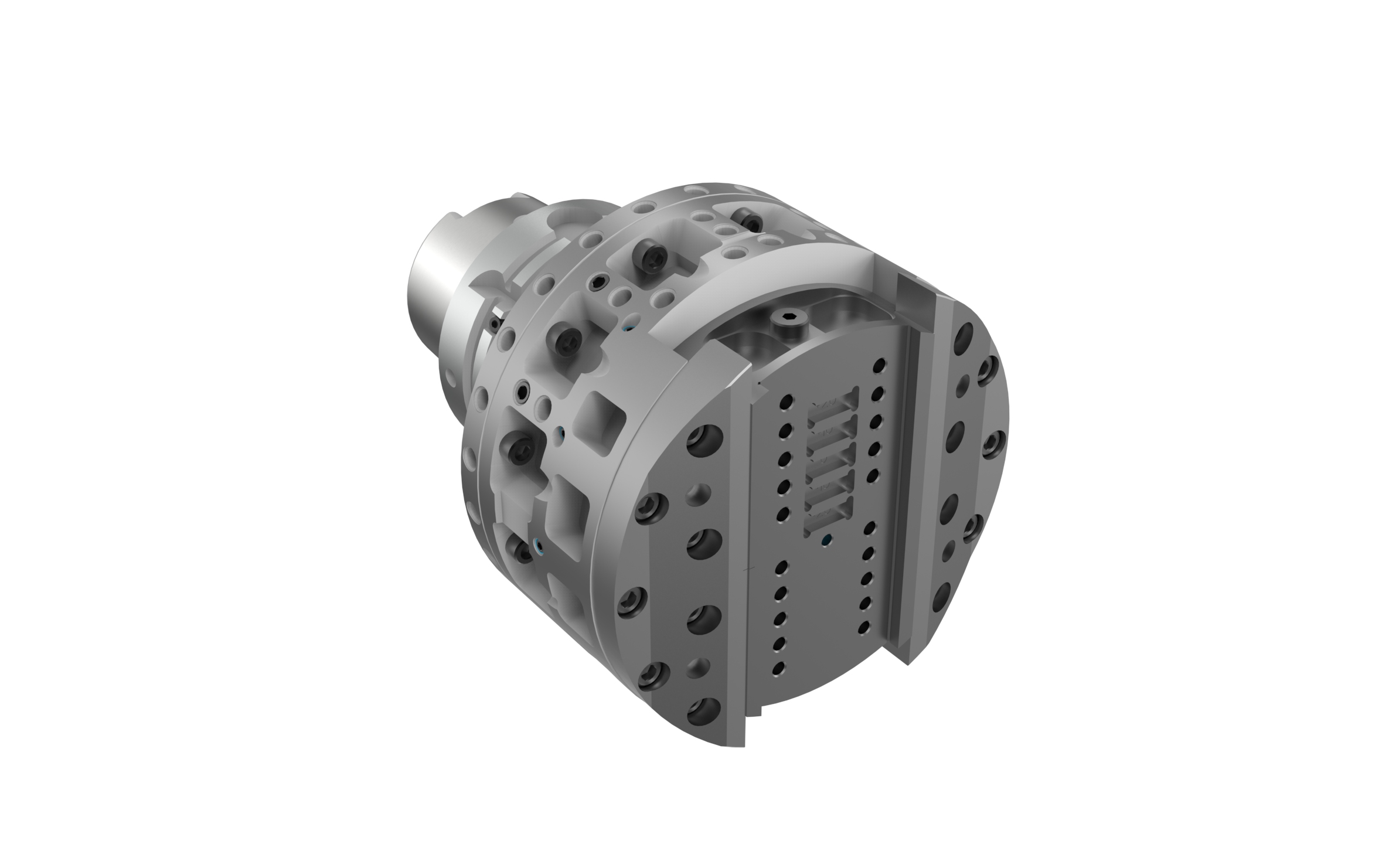

遮断弁ハウジング

EN-GJL-250製遮断弁ハウジング

お客様の初期の加工状況

/Absperrventil.607-2-.jpg)

- 多種多様な部品(DN 65 - DN 300)

- マシニングセンターでのフレキシブルな加工が必要

- 設定された表面仕様を製作することで能力が試される部品加工

ソリューションの特徴

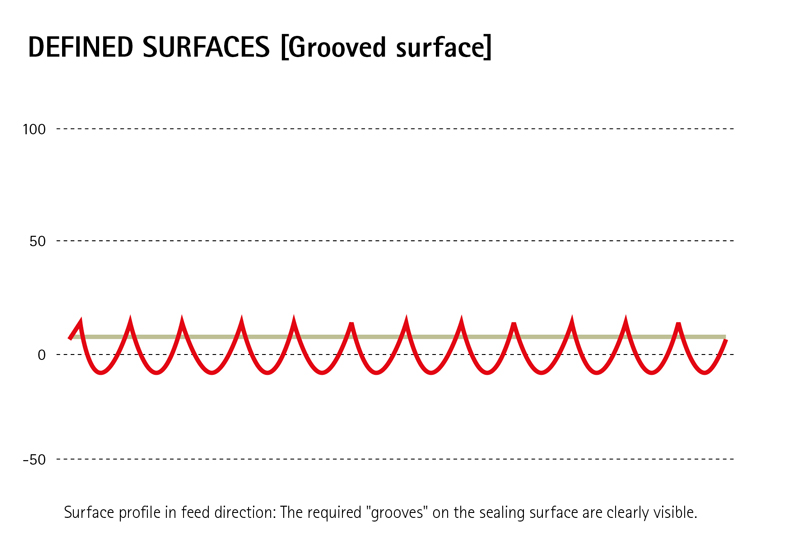

- 高い送り速度を実現、設定された凸凹段差Ra12.5では最小送り速度fz=0.8mmが必要

- 大きな半径方向ストロークとモジュール式ツールインターフェースにより、製造部品間で少数の工具を使用可能

- 自動工具交換

- 姉妹工具を使用することで、加工時間の短縮が可能

- 柔軟なプロセスにより、セッティングフィクスチャーでのプリセットが可能

- インサートテクノロジーによる工具材料費の低減

ツールハイライト

- 自動工具交換でフレキシブルな工具使用が可能

- セットアップツールは5段階にオフセットでき、大きな径範囲に対応

- 最適なクーラントをセットアップツールから直接刃先に集中供給

利点

- 1つのツールシステムで幅広い部品をカバー可能

- フランジ面とシートリングの加工をワンチャックで実現可能

- 再クランプ誤差がなく、生産性を最大化

- 制御技術により、バリのない輪郭移行と短いサイクルタイム、設定された表面仕様の生産が可能

- 工具磨耗による公差や品質の柔軟な修正が可能