30.05.2023

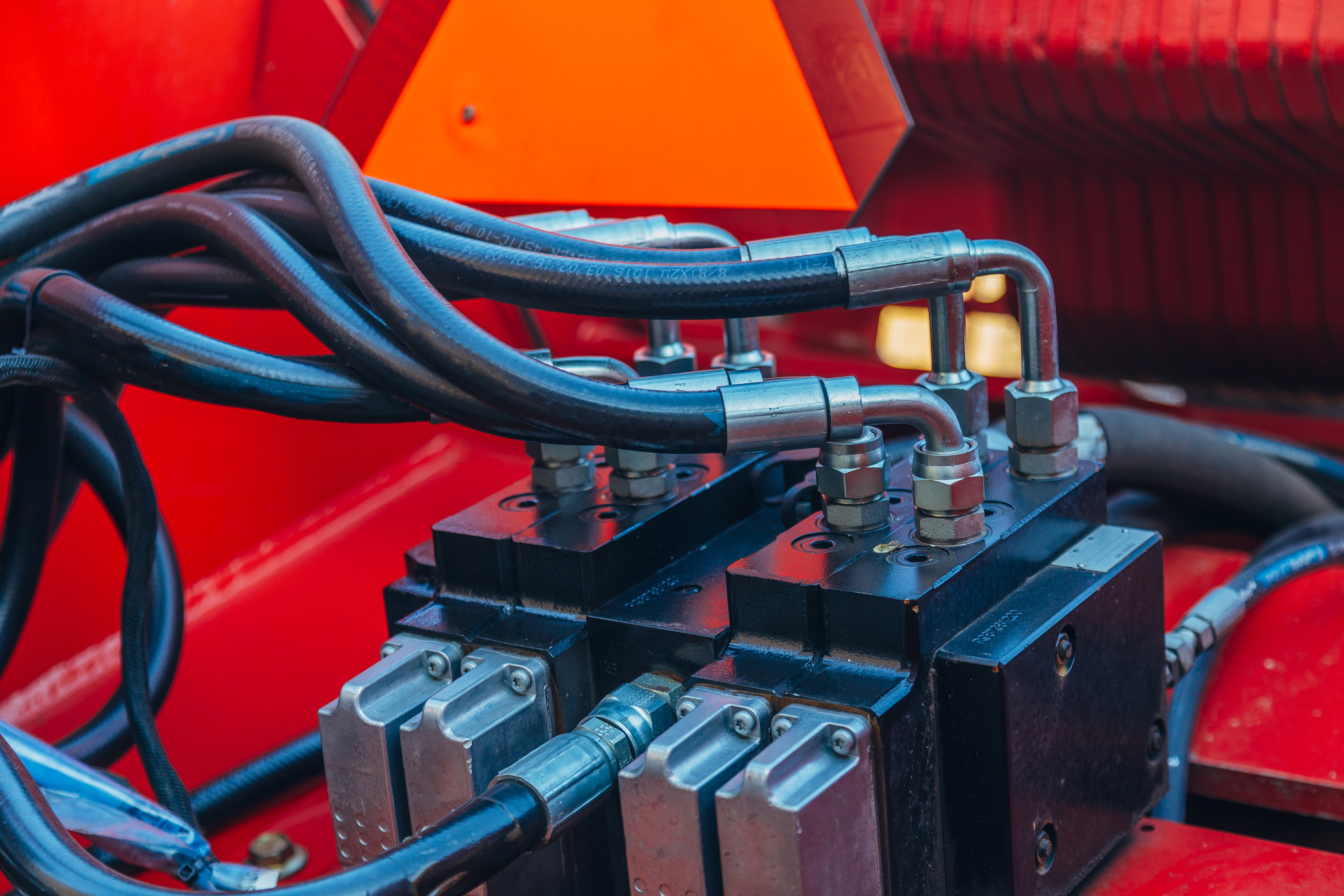

Precisely fitting solutions for hydraulic valve housings

Customised machining solutions for individual manufacturing situations

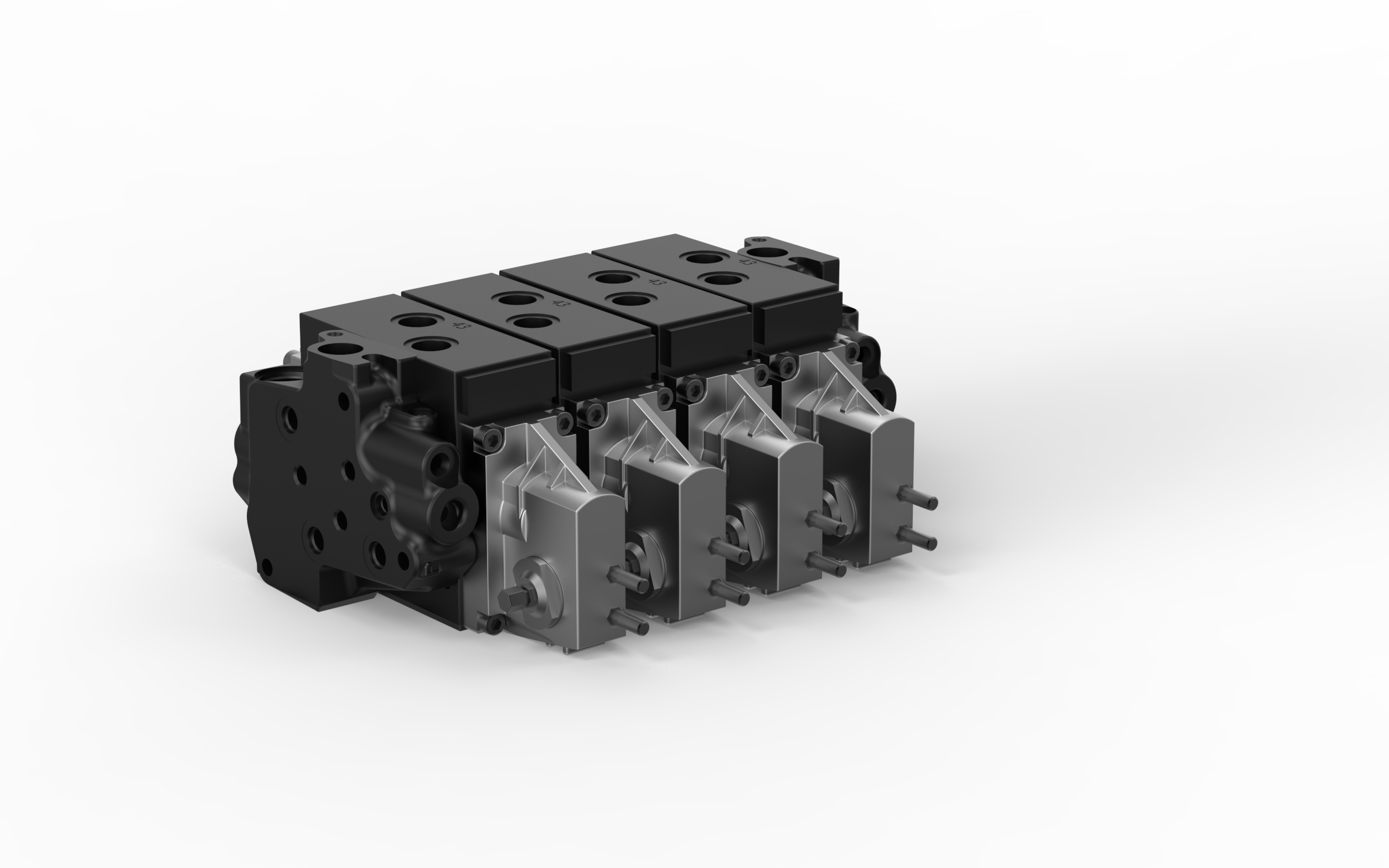

The production of hydraulic valve housings is the supreme discipline in the world of fluid power technology. As a technology partner, MAPAL supports the customer in the complete process design. The experts pay particular attention to the cost drivers that are often found in the functionally relevant bores. Based on the respective honing process, the component requirements and batch sizes, MAPAL designs the optimum machining strategy in dialogue with the customer.

Based on the applications already implemented for existing customers, MAPAL has developed specific solutions for hydraulic valve housings. They reflect many customer and component requirements. For MAPAL’s expertise in machining the spool bore has been in demand for years. The gap dimension with the spool depends on the accuracy of this bore, so that the hydraulic oil can only flow in the required direction without leaking. This is very narrowly defined in modern hydraulic valves. The roundness, cylindrical form, straightness and surface quality of this bore are therefore crucial.

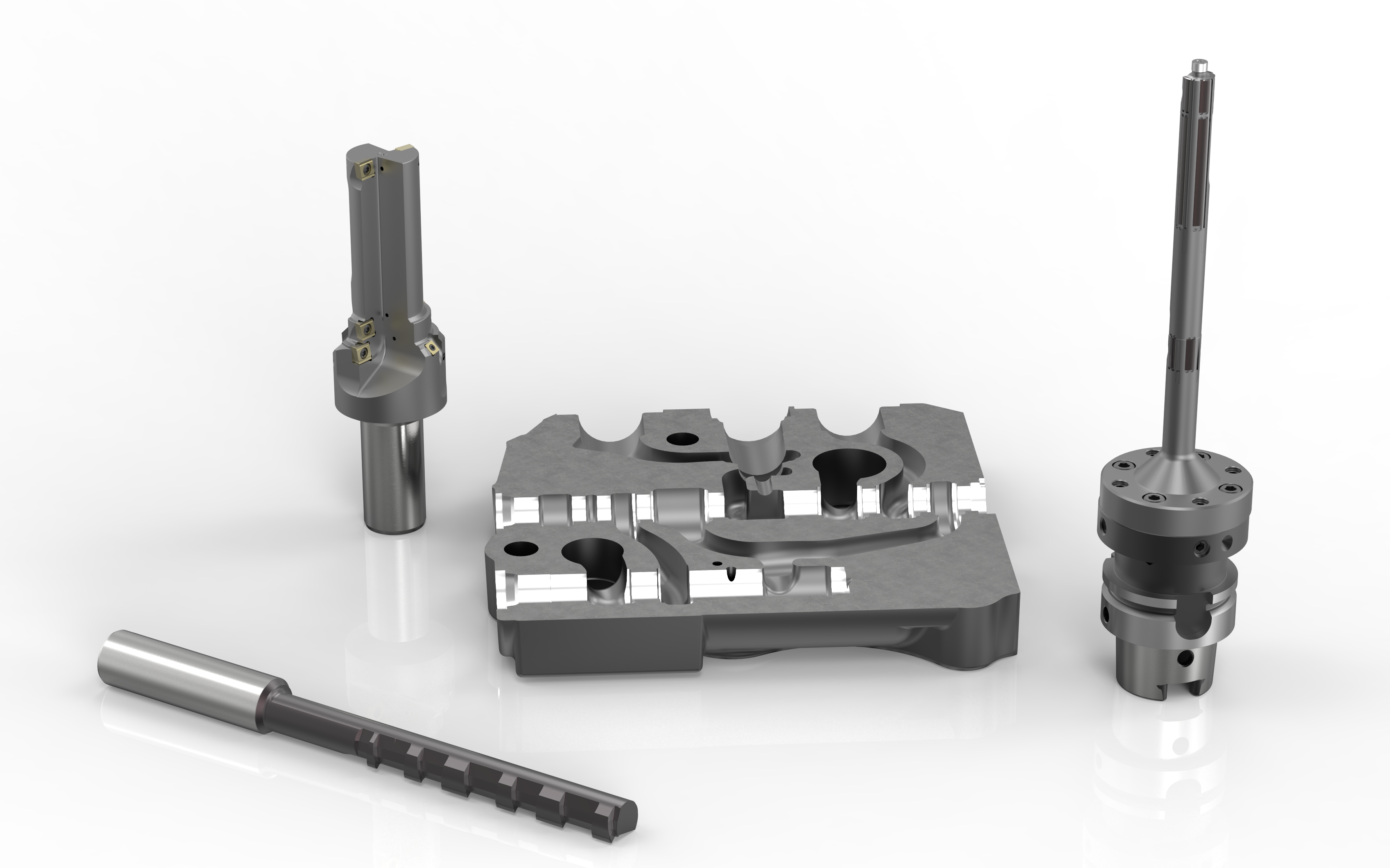

Clear best practice examples each deal with specific production situations. MAPAL designs the tools for these in a way that always results in the most cost-efficient process. That includes swiftly completing pre-machining and semi-finishing– all while keeping an eye on subsequent processes further down the line, such as honing.

Application solutions for every situation

The first of the solutions presented for the machining of a hydraulic valve housing is rather unusual for MAPAL, as it does not include a fine boring tool for finishing. After piloting, boring and circular milling of the spool bore, in this instance, a multi-bladed reamer performs the final machining step before honing. With its selection of tools, MAPAL demonstrates that some tasks can be tackled with a high degree of accuracy without the need for an adjustable special tool. The concept is particularly suitable for smaller and medium quantities.

If large quantities and high levels of accuracy are sought in series production, the second application solution is the right blueprint. The key difference is the fine boring tool used for fine machining. It meets the high standards for spool bore and compensator bore production. The EasyAdjust-System and guide pads offer reliable fine machining with easy handling. As the customers’ technology partner, MAPAL defines with them the extent to which a concluding honing process can be scaled down or even omitted.

Kontakt

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Tel.: +49 7361 585 3342