01.05.2019

Digitalisation for regrinding of tools – Transparency and efficiency courtesy of c-Com

MILLER in Altenstadt has digitized the reconditioning of solid carbide tools

Reconditioning tools represents a significant expense for manufacturing companies. But regrinding and recoating to manufacturer quality are essential to continuously make use of the full potential of the tools. There’s nothing especially critical about that. What often is critical about reconditioning, though, is the process of registering and managing the tools at the regrinding company. To create transparency for customers, safeguard a reconditioning service that takes just a few days and take some of the strain off its own employees, MILLER GmbH & Co. KG therefore uses c-Com GmbH for its regrinding management.

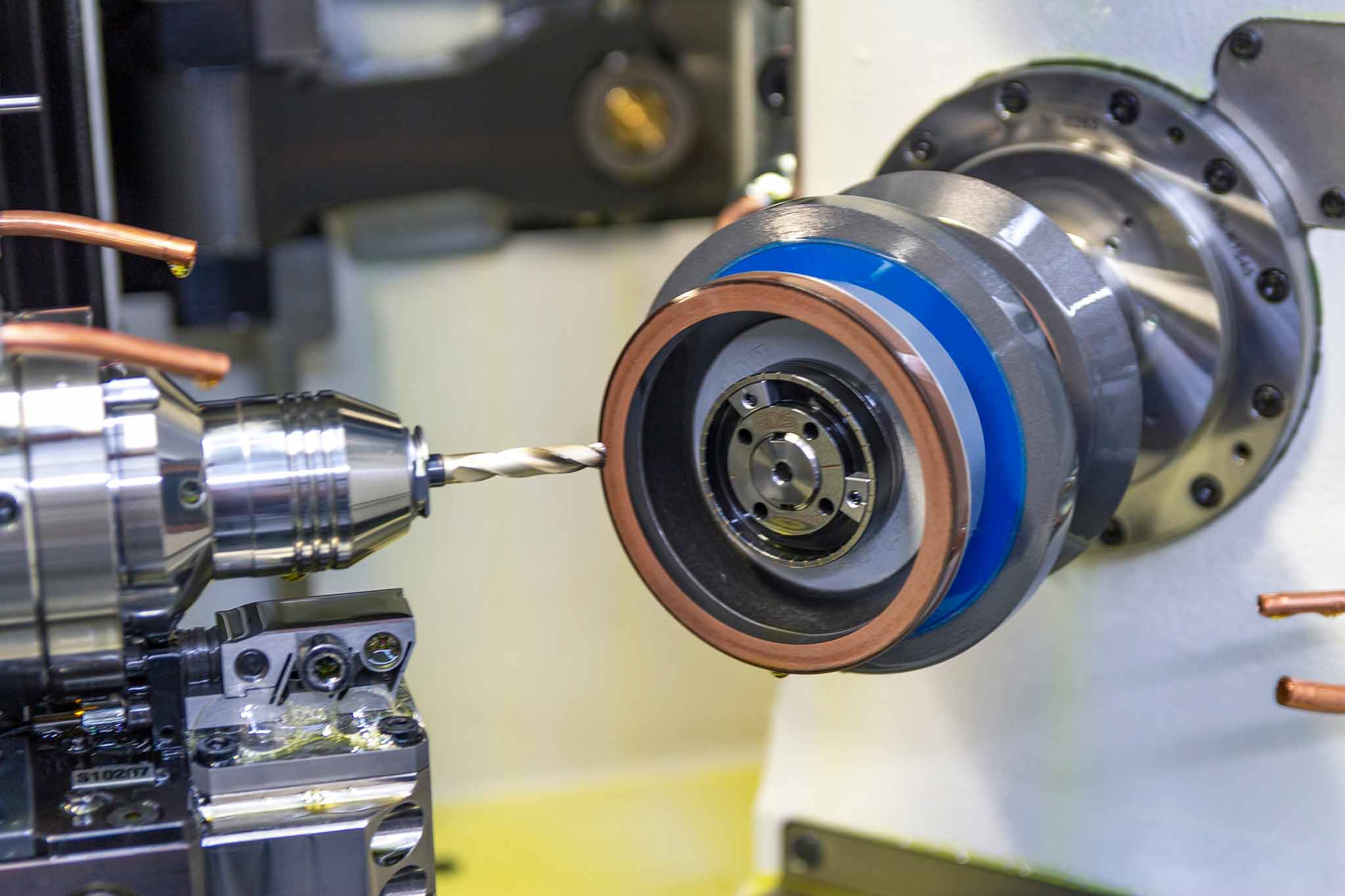

Every week, around 6,000 tools arrive at MILLER in Altenstadt, Germany, for regrinding. “We are seeing robust growth of roughly 20% every year in tool reconditioning,” says Stephan Loska, Director of Technical Projects and International Service at the manufacturer of solid carbide tools. Consequently, something of a “company within a company” has grown up over the years, dedicated solely to regrinding solid carbide drills and milling cutters. It is important to note that exactly the same machinery, software and grinding wheels are used here as for manufacturing new tools. “That is how we reliably ensure that tools are reconditioned to manufacturer quality,” says Loska. There are around 30 employees working on the machines over three shifts, plus another four employees in incoming goods and five in customer service working exclusively on regrinding.

In 2018, the supervisors under Stephan Loska faced the challenge to align a significant upturn in incoming orders with the customer expectation of a few days of run-through time. “It was clear that we would need either to expand our capacity considerably or to refine and simplify our processes,” explains Loska. Incoming goods in particular offered a great deal of potential.

A manual process - time-consuming and prone to mistakes

about these tools, if there is any at all, is printed on the delivery note. “That meant that our

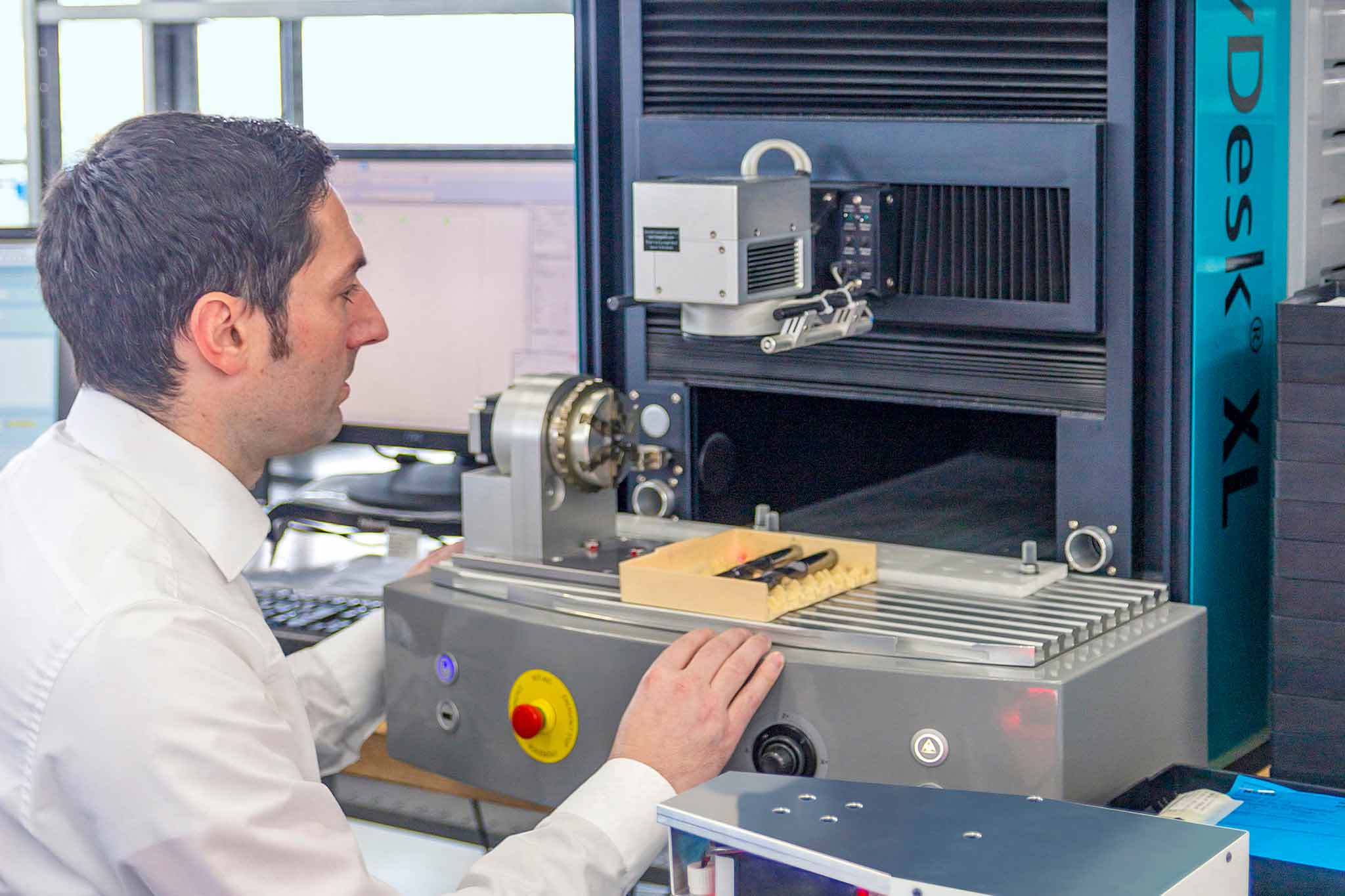

employees had to sort through all the tools and compare their order numbers, which on tools with small diameters can often be read only with the aid of a magnifying glass, against the items on the delivery note,” says Spiegl. The next item on the agenda was to inspect the tools to determine whether they could be reground. Criteria that could rule a tool out include its condition, its minimum length or customer specifications such as the maximum number of regrinding operations. Following tool identification, the check Thanks to c-Com and the specifically developed scanner, registering tools at incoming goods is now a much faster process. Measurements are automatically transferred from the Bluetooth-enabled callipers to c-Com at the touch of a button. as to whether the items and quantities match those on the delivery note and the diagnostic process to determine whether the tools can be reground, all this information needed to be entered manually in the ERP system (SAP) so that a service report and order confirmation could be created. “For a delivery of 80 tools, this largely manual process took around two hours,” explained Spiegl. In addition to the amount of time taken, this process was susceptible to typographical and transcription errors.

New process with regrinding management from c-Com

Service report with one click

Once all tools have been scanned, colour-coding is used to indicate whether all items on the delivery note are fully accounted for. The c-Com module keeps up constant correspondence with SAP, which means that a single mouse click is all it takes to create an automated internal service report. “With c-Com, we have also switched straight to labels,” adds Spiegl. In other words, instead of having to deal with multiple sheets of A4 paper for each order, the new c-Com process involves generating a label and affixing it to the relevant box.

When the box reaches the diagnostics area, this label is scanned, and the tools are inspected to determine whether they can be reground. All criteria concerning the tool in question and all exclusion criteria are entered in c-Com. The employee scans the tool again and is shown information about it immediately; for example, that a tool needs to be checked for minimum length.The employee uses a set of callipers linked to c-Com via Bluetooth to measure the tool before transmitting the findings to c-Com at the push of a button. c-Com compares the actual measurement with the intended measurement and indicates whether the tool can in fact be reground. If the employee identifies chipping on the cutting edge, for example, he or she selects this on the list of exclusion criteria. Once all tools have been inspected, the order confirmation is issued by a single click. This automatically shows which tools cannot be reground and why.