Empower Your Aluminium Machining

La clave está en la ingeniería

Con décadas de experiencia en el diseño, producción y uso de herramientas para el mecanizado de aluminio, MAPAL es el socio tecnológico líder para el mecanizado de componentes de aluminio. Para poder ofrecer a sus clientes procesos de mecanizado óptimos, MAPAL ofrece, además de un amplio surtido de productos y aplicaciones, también una amplia experiencia en el mercado, los materiales y la ingeniería. Solo mediante la interacción de todos los factores que influyen y una cooperación exitosa de los socios puede alcanzarse todo el potencial de un proceso de mecanizado: este es el sentido de la ingeniería en MAPAL.

El cliente en el centro de atención

Sectores y componentes

Desafíos del mecanizado del aluminio

Productos y aplicaciones

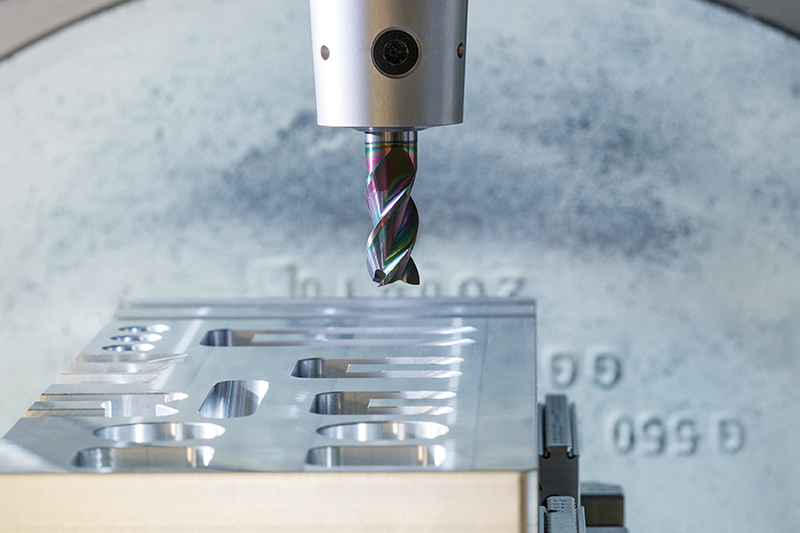

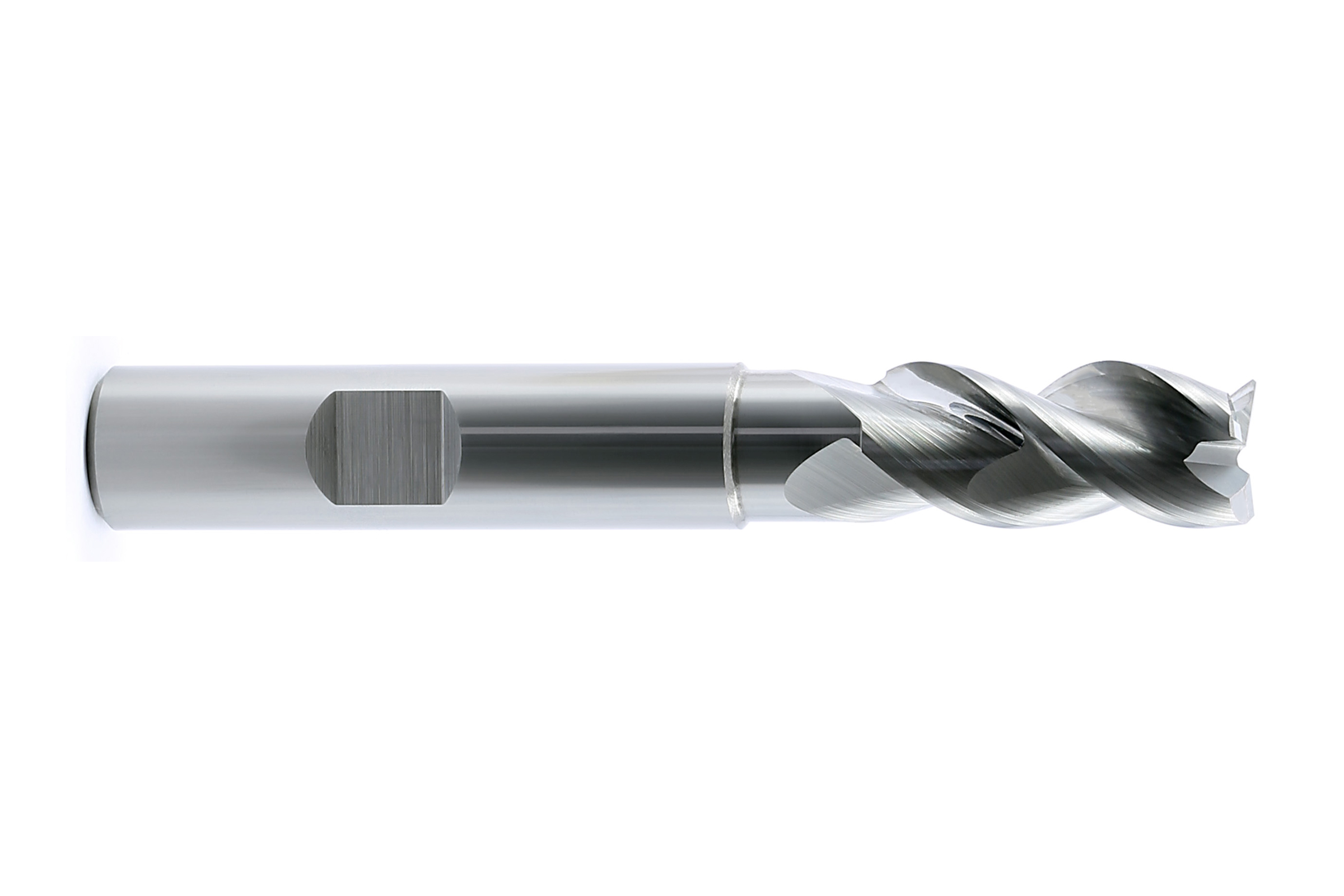

Fresado con metal duro macizo

Fresado con PCD

Fresado con insertos de corte intercambiables

Taladrado

Escariado

Sujeción

Beispiele aus der Praxis

MAPAL Services

Mit dem Servicebaustein Engineering garantiert MAPAL eine schnelle, präzise und sichere Fertigung. Im Bereich Logistics und Maintenance können weitere Einsparpotenziale erschlossen werden. Und im Bereich Training sorgt MAPAL dafür, dass das gesammelte Spezialisten-Know-how transparent und vollständig dem Kunden zur Verfügung steht – dies ermöglicht Kunden einen entscheidenden Vorsprung zum Mitbewerber.

Bei allen Serviceangeboten von MAPAL stehen optimale Prozesse und eine umfassende Betreuung auf dem Weg in Richtung Industrie 4.0 im Mittelpunkt. Immer mit dem Ziel, maßgeblich zu einer reibungslosen, produktiven und wirtschaftlichen Fertigung beim Kunden beizutragen.

Vorteile:

- Lösungen für komplette Werkstücke inklusive Werkzeugen, Vorrichtungen, NC-Programm und Inbetriebnahme

- Gesamte Prozessauslegung und Umsetzung aus einer Hand

- Weltweit schnelle und flexible Betreuung vor Ort

- Effiziente und kostenoptimierte Werkzeugtechnologie

- Optimale Abstimmung von Werkzeug, Werkstück, Vorrichtung und Maschine

- Höchste Produktqualität, Prozesssicherheit und Wirtschaftlichkeit von Anfang an

- Schneller Durchlauf von der Planung bis zur Umsetzung bei maximaler Planungssicherheit

/-P3A1692-1-.jpg)