Pequeñas carcasas de motores eléctricos

Ejemplo de accionamiento de una e-bike

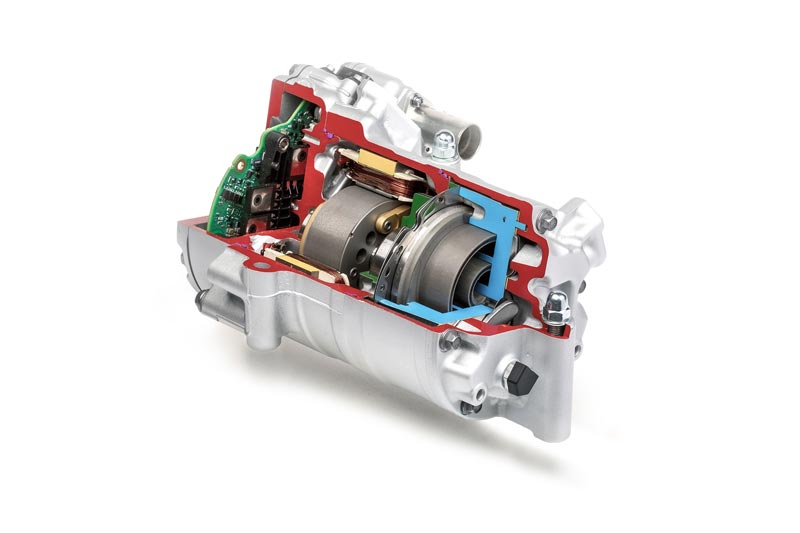

La movilidad eléctrica lleva mucho tiempo integrada en nuestra vida cotidiana. Los primeros motores eléctricos que llegaron al gran público fueron los de las bicicletas. Para su producción, la carcasa del motor es uno de los componentes que supone un desafío, ya que debe ser pequeña y ligera, pero a la vez muy precisa.

Durante las pasadas décadas, MAPAL ha reunido una amplia experiencia en el mecanizado de carcasas de motor pequeñas tanto de aluminio como de magnesio, por ejemplo carcasas para motosierras, ciclomotores o cortacéspedes. Sin embargo, con la electrificación los requisitos de precisión han aumentado de nuevo.

CARACTERÍSTICAS

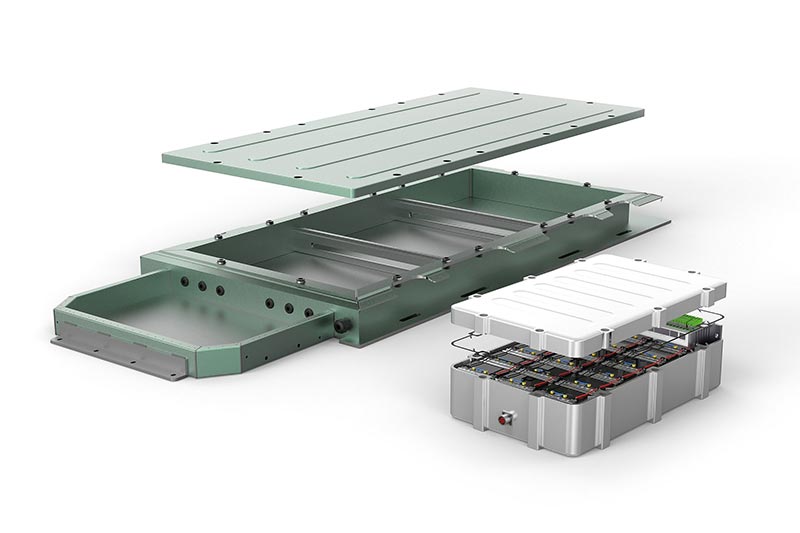

- De dos o tres piezas (carcasa y tapa)

- Carcasa de fundición a presión de aluminio o magnesio

- Componentes inestables de paredes finas (propensos a vibraciones)

- Trazados de contorno en varios niveles

- Altos requisitos geométricos y dimensionales (tolerancias de forma, marcha y posición)

REQUISITOS DE MECANIZADO

- Circularidad < 0.01 mm

- Tolerancia de diámetro IT7

- Rigurosidad media Rz < 10 μm

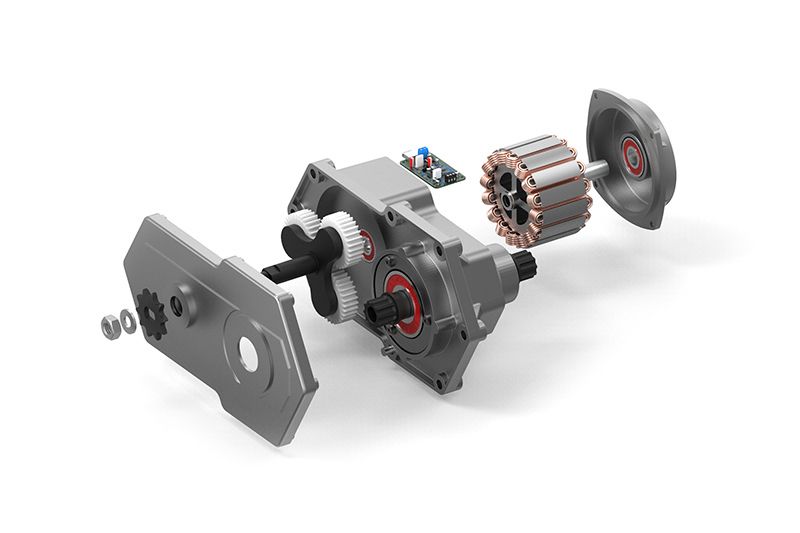

La herramienta PCD trabaja los orificios de rodamiento y posición en la carcasa de magnesio

En el mecanizado de orificios de rodamiento y posición en una carcasa específica de magnesio, las fuertes vibraciones representan un desafío, ya que el componente es extremadamente delgado en la zona del tercer agujero de rodamiento. La herramienta debe remover 0.6-1 mm de material en los barrenos previstos.

Se deben cumplir los siguientes parámetros:

- Circularidad < 0.01 mm

- Tolerancia de diámetro IT7

- Rigurosidad media Rz < 10 μm

MAPAL utiliza para ello una herramienta combinada de PCD compleja y de múltiples etapas, que procesa los tres agujeros de rodamiento y los orificios de posición del asiento del cojinete en una sola operación, de forma segura y dentro de las tolerancias requeridas.

La herramienta funciona con los siguientes datos de corte:

- Revoluciones 8,000 min-1

- Velocidad de avance 3,200 - 4,800 mm/min

- Velocidad de avance 0.1-0.15 mm

Taladrado y fresado combinados en una sola herramienta

Otra herramienta combina operaciones de fresado y taladrado en una carcasa de magnesio. Durante las etapas de perforación, cuando se trabaja el agujero de rodamiento y los orificios de posición, se utiliza una etapa de fresado para fabricar el sello de estanqueidad. Al utilizar esta herramienta, también era importante evitar las vibraciones y mantener baja la presión de corte. Los expertos en herramientas lo consiguieron optimizando el número de dientes y la geometría de la etapa de fresado. Esto también evita que se astillen las ranuras.

Datos de corte de la etapa de fresado:

- Revoluciones 8,000 min-1

- Velocidad de avance 7,200 mm/min

- Avance 0.15 mm

MAPAL ofrece un paquete completo para el mecanizado de pequeñas carcasas de aluminio o magnesio.

En primer lugar, las herramientas PCD y de metal duro son ideales para el mecanizado de estos dos materiales. En función de los requisitos y la complejidad, MAPAL diseña el concepto adecuado, incluyendo todas las herramientas y mandriles. Herramientas combinadas, cada una cubriendo varios pasos de trabajo, hacen el proceso particularmente económico.