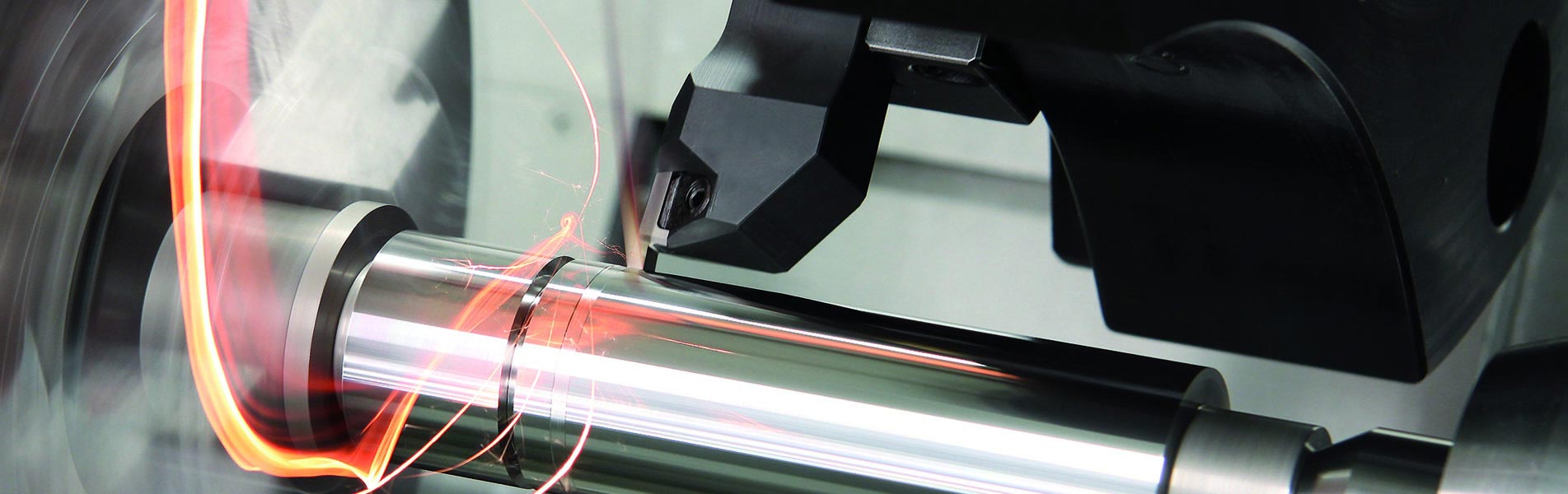

Torneado competente - Eficiencia, precisión y eficacia

Gracias a su dilatada experiencia con los materiales de corte de gran dureza PcBN y PCD que se utilizan en los segmentos del taladrado incisor, fresado y escariado, MAPAL ha dquirido profundos conocimientos que también son aplicables al torneado. El principal centro de atención es el torneado en duro.

La oferta de MAPAL incluye soluciones de herramientas especiales de torneado sin torsión, para el mecanizado completo de superficies de sellar, superficies de cojinete y asientos de cojinete en tornos. De esta forma se evitan las laboriosas tareas de cambio de posición de las piezas de trabajo que se dan en las máquinas de rectificado.

Para aprovechar óptimamente las costosas plaquitas redondas PcBN, MAPAL ha desarrollado un sistema con plaquitas redondas indexables que permite un giro sencillo y definido de la plaquita en la máquina. De esta manera, la plaquita puede aprovecharse óptimamente. El sistema de tronzado flexible VersaCut aporta una estabilidad máxima para el tronzado de metales endurecidos con PcBN. Proporciona las condiciones ideales para los requisitos especiales del mecanizado de materiales duros. Actualmente MAPAL dispone de una amplia selección de plaquitas de corte reversibles PCD y PcBN para el torneado en duro, con una amplia selección de materiales de corte y de diseños de filos.

La oferta de MAPAL incluye soluciones de herramientas especiales de torneado sin torsión, para el mecanizado completo de superficies de sellar, superficies de cojinete y asientos de cojinete en tornos. De esta forma se evitan las laboriosas tareas de cambio de posición de las piezas de trabajo que se dan en las máquinas de rectificado.

Para aprovechar óptimamente las costosas plaquitas redondas PcBN, MAPAL ha desarrollado un sistema con plaquitas redondas indexables que permite un giro sencillo y definido de la plaquita en la máquina. De esta manera, la plaquita puede aprovecharse óptimamente. El sistema de tronzado flexible VersaCut aporta una estabilidad máxima para el tronzado de metales endurecidos con PcBN. Proporciona las condiciones ideales para los requisitos especiales del mecanizado de materiales duros. Actualmente MAPAL dispone de una amplia selección de plaquitas de corte reversibles PCD y PcBN para el torneado en duro, con una amplia selección de materiales de corte y de diseños de filos.

Innovaciones en el torneado en duro

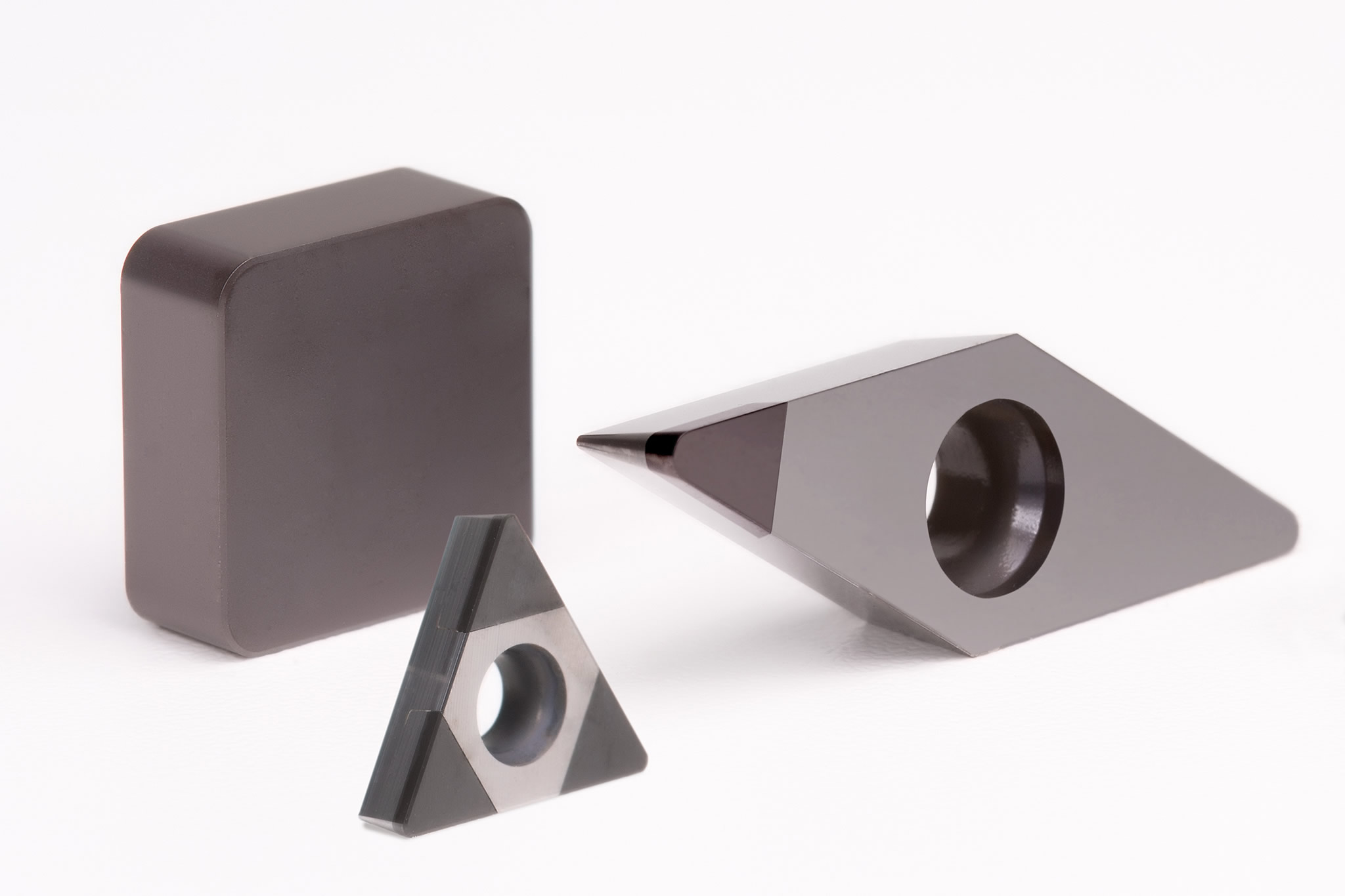

Insertos intercambiáveis PcBN e PCD

A partir de sus conocimientos en los segmentos del taladrado incisor, fresado y escariado, MAPAL ha desarrollado plaquitas de corte reversibles con PCD y PcBN para las aplicaciones con requisitos especialmente exigentes. El diamante policristalino (PCD) y el nitruro de boro cúbico policristalino (PcBN), dos materiales de corte de gran dureza, son indispensables en el mundo de producción actual.

Insertos intercambiáveis PcBN

Os materiais de corte PcBN da MAPAL criam, com sua elevada dureza térmica, resistência

ao desgaste e rigidez de arestas, os pré-requisitos ideais para uma fabricação rentável. Em muitos casos é possível reduzir significativamente o tempo de usinagem e, consequentemente, os custos da peça, mantendo ao mesmo tempo uma ótima qualidade do componente.

Vantagens:

ao desgaste e rigidez de arestas, os pré-requisitos ideais para uma fabricação rentável. Em muitos casos é possível reduzir significativamente o tempo de usinagem e, consequentemente, os custos da peça, mantendo ao mesmo tempo uma ótima qualidade do componente.

Vantagens:

- Tipos de PcBN para corte contínuo e interrupções de corte

- Grande seleção disponível de geometrias padrão e modelos de chanfro para otimizar o tempo de vida útil e a qualidade

- Modelos de equipamento múltiplo para maior rentabilidade das ferramentas

- Insertos intercambiáveis com tolerância G de alta precisão

Insertos de corte PKD

O PKD é ideal como material de corte na usinagem destes materiais. Com sua alta dureza e resistência ao desgaste obtém-se valores de corte e tempos de vida útil elevados, mesmo na usinagem de materiais extremamente abrasivos. Isso garante a rentabilidade da usinagem por corte. A MAPAL desde cedo apostou no PKD na concepção de ferramentas de alto desempenho e adquirindo muitos anos de experiência e um amplo know-how nessa área. Diferentes tarefas de usinagem com requisitos variáveis quanto à abrasividade, geometria da peça e máquinas são resolvidas com PKD.

Vantagens:

Vantagens:

- Valores de corte e rentabilidade elevada

- Alta precisão das geometrias das arestas de corte

- Os mais modernos métodos de fabricação trazem opções adicionais