Empower Your Aluminium Machining

Engineering is the key

With decades of experience in the design, production and application of tools for aluminium machining, MAPAL is the leading technology partner for the machining of aluminium components. In order to be able to offer customers optimum machining processes, MAPAL provides market, material and engineering expertise in addition to a comprehensive product and application portfolio. The full potential of a machining process can only be realised through the interaction of all influencing factors and cooperation in a spirit of partnership - this is what MAPAL stands for.

Focus on the customer

Industries and components

Challenges of aluminium machining

Products and applications

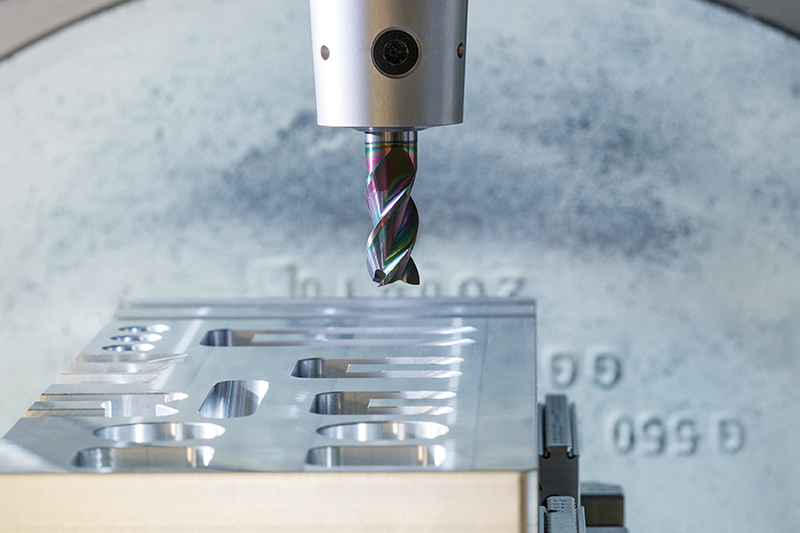

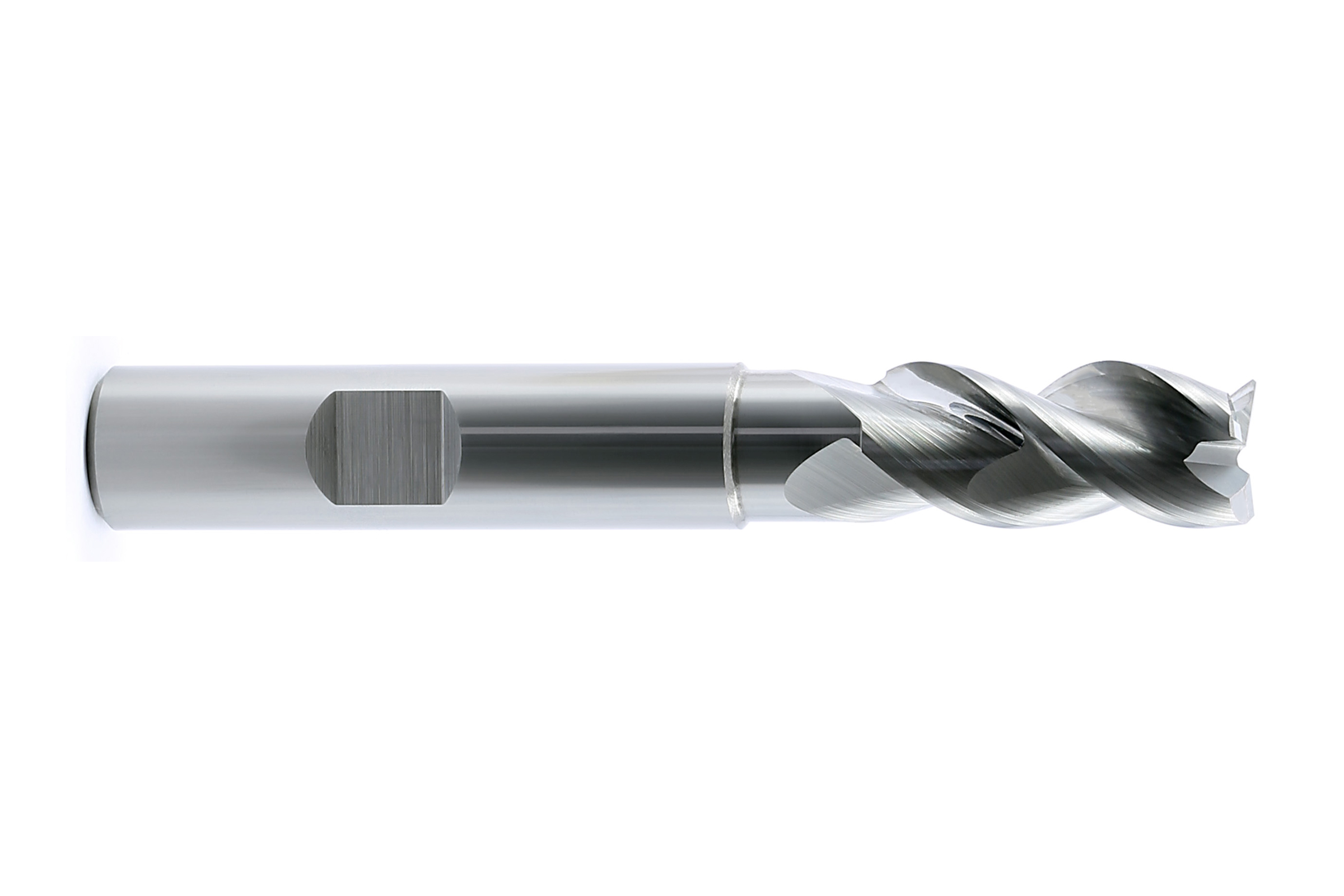

Milling with solid carbide

Milling with PCD

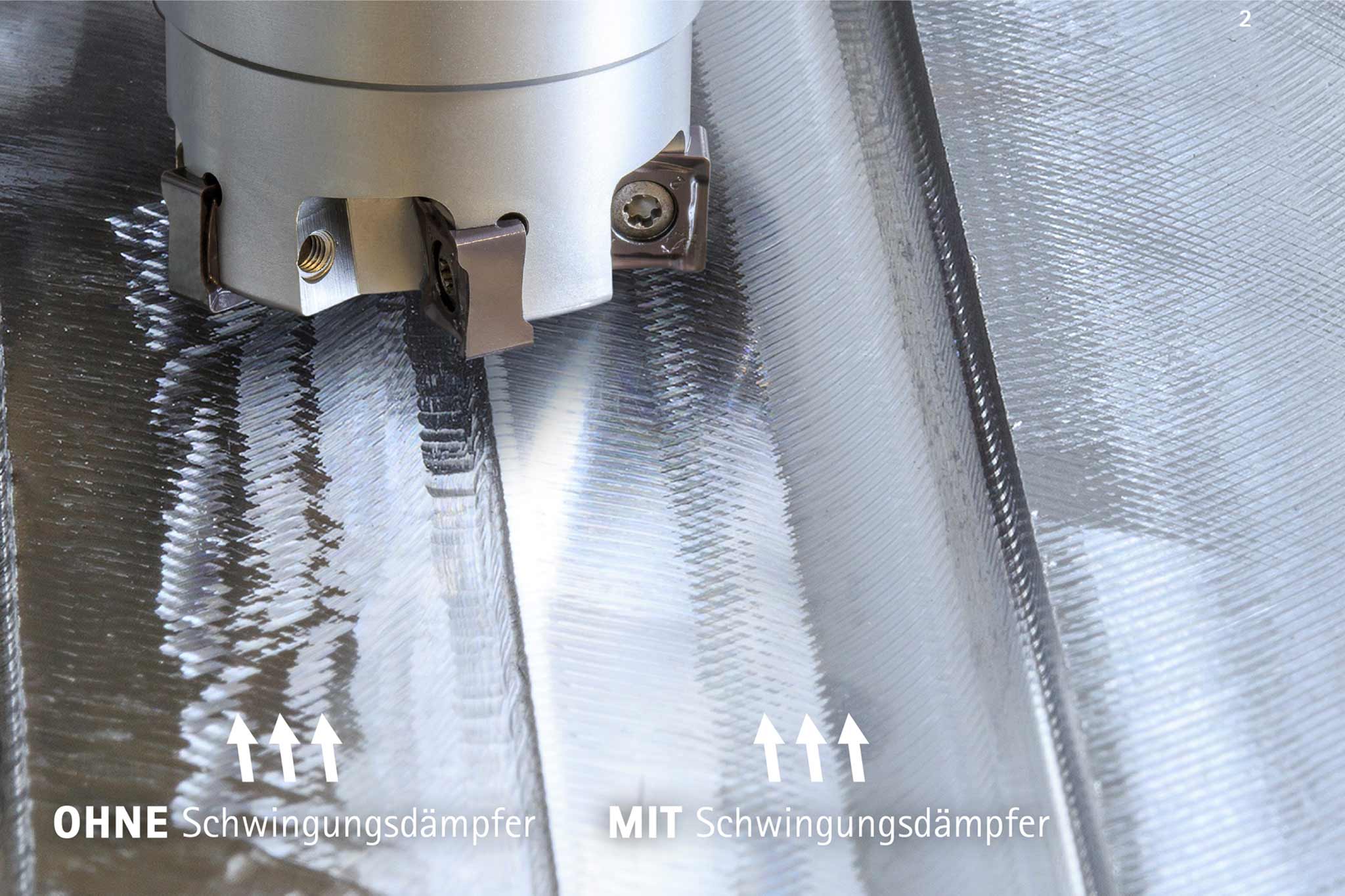

Milling with indexable inserts

Drilling

Reaming

Clamping

Examples from practice

MAPAL Services

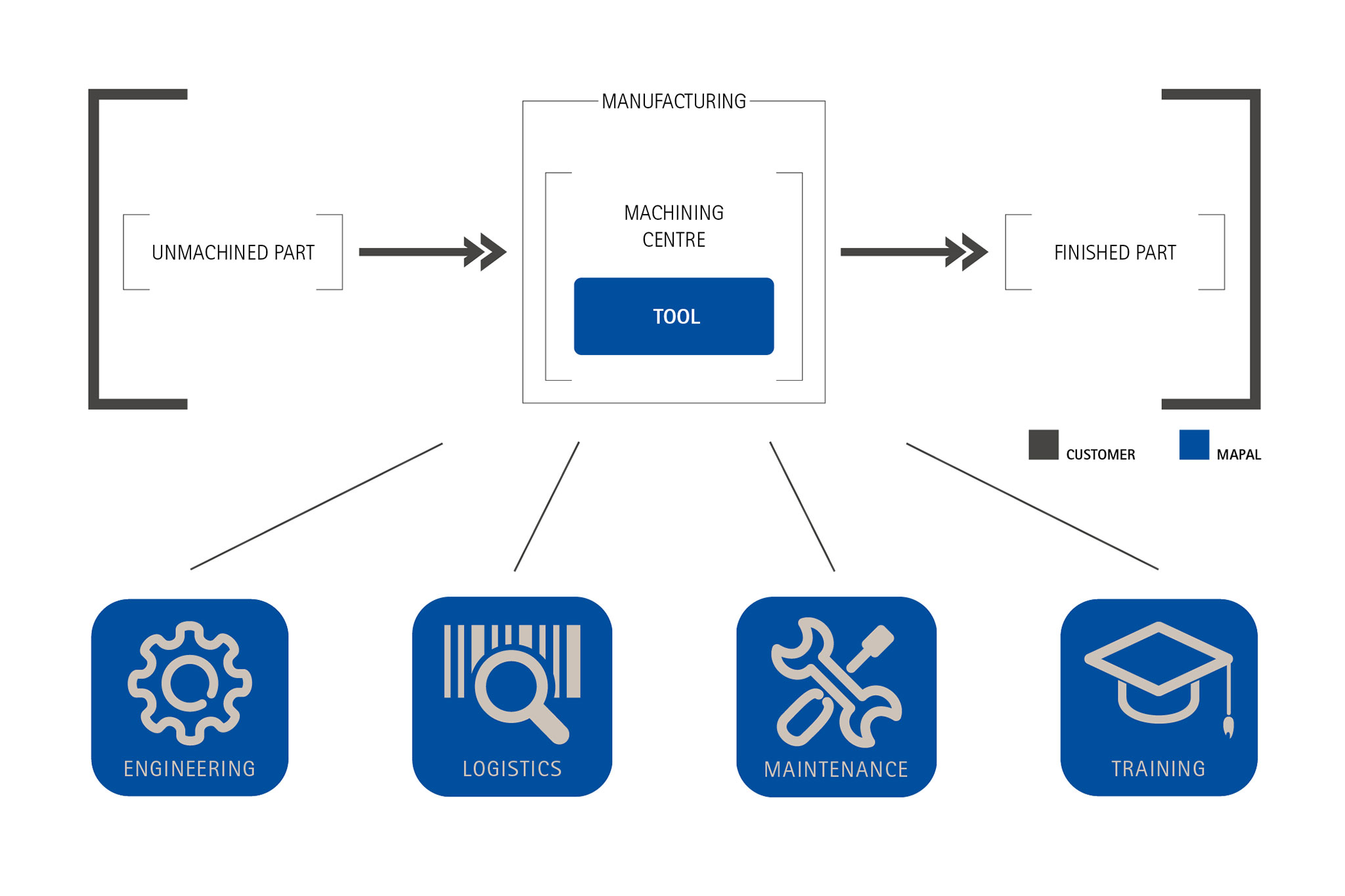

With the engineering service module, MAPAL guarantees fast, precise and safe manufacturing. Further savings potential can be tapped in the area of logistics and maintenance. And in the area of training, MAPAL ensures that the specialist know-how it has gathered is transparently and completely available to the customer – this gives customers a decisive lead over their competitors.

All of the services offered by MAPAL focus on optimal processes and comprehensive support on the way to Industry 4.0. The goal is to always significantly assist the customer in achieving smooth, productive and economical manufacturing.

Advantages:

- Solutions for complete workpieces including tools, devices, NC programs and commissioning

- Complete process design and implementation from a single source

- Fast and flexible on-site support worldwide

- Efficient and cost-optimised tool technology

- Optimum coordination of tool, workpiece, equipment and machine

- Highest product quality, process reliability and cost-effectiveness right from the start

- Fast throughput from planning to implementation with maximum planning security

/-P3A1692-1-.jpg)