Getting started in the die & mould sector

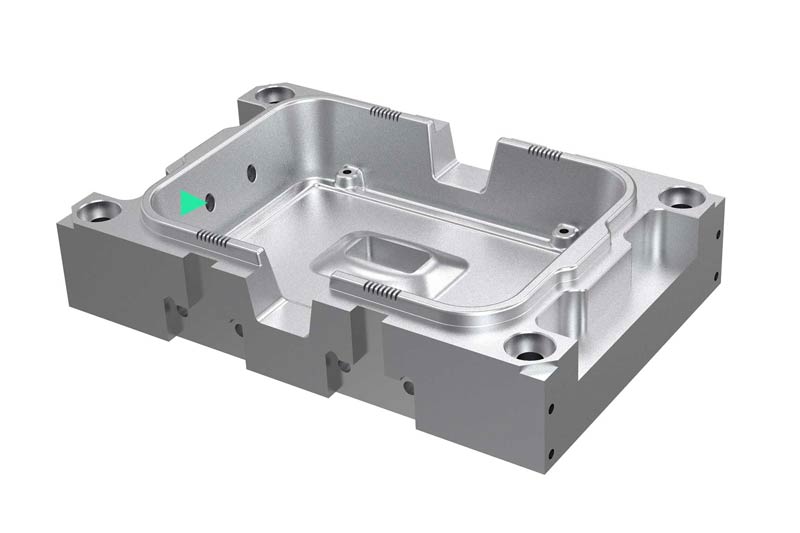

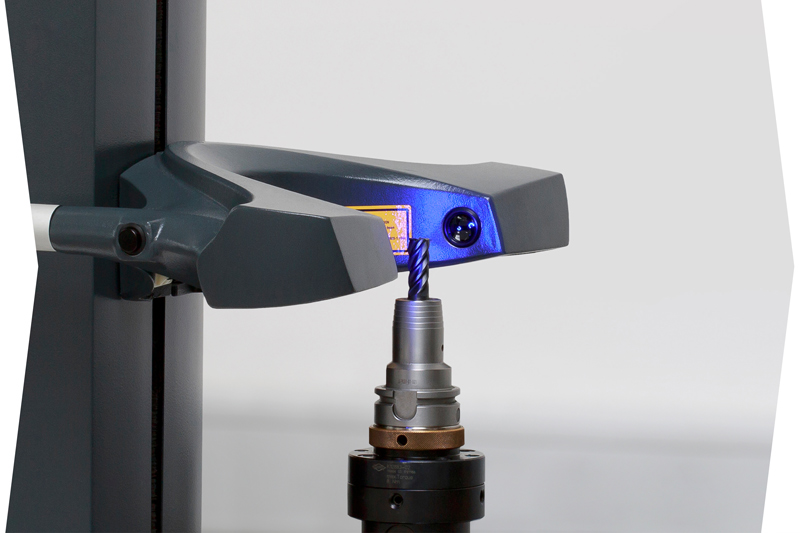

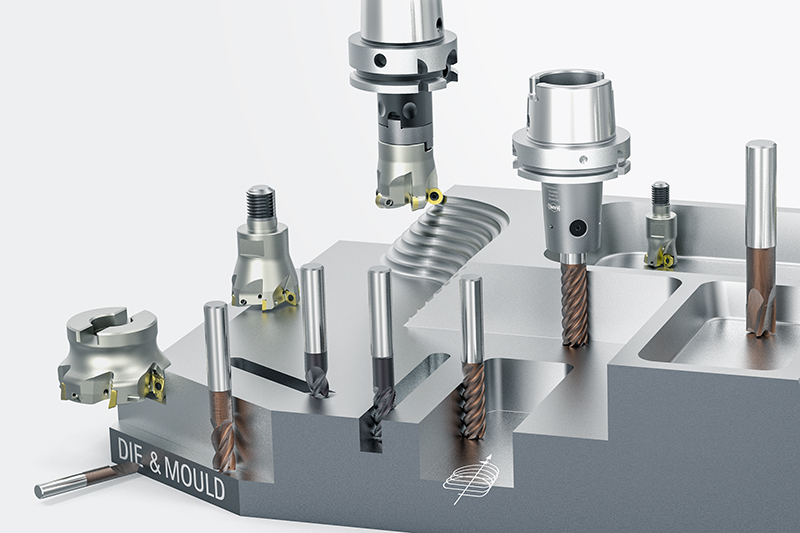

It is precisely these aspects that make MAPAL successful in sectors such as the automotive industry, machine engineering and the aerospace industry. Now the precision tool manufacturer is also offering efficient and economical solutions for the complete machining process in the die & mould sector. Versatile and precise high-performance tools and special tool holders with narrow contours and a precise radial run-out minimise polishing effort and reworking thanks to a constant surface finish in the milling process.

Tool range for mould making

Componenti e materiali

- Acciaio e acciaio temprato

-

Acciaio e acciaio temprato

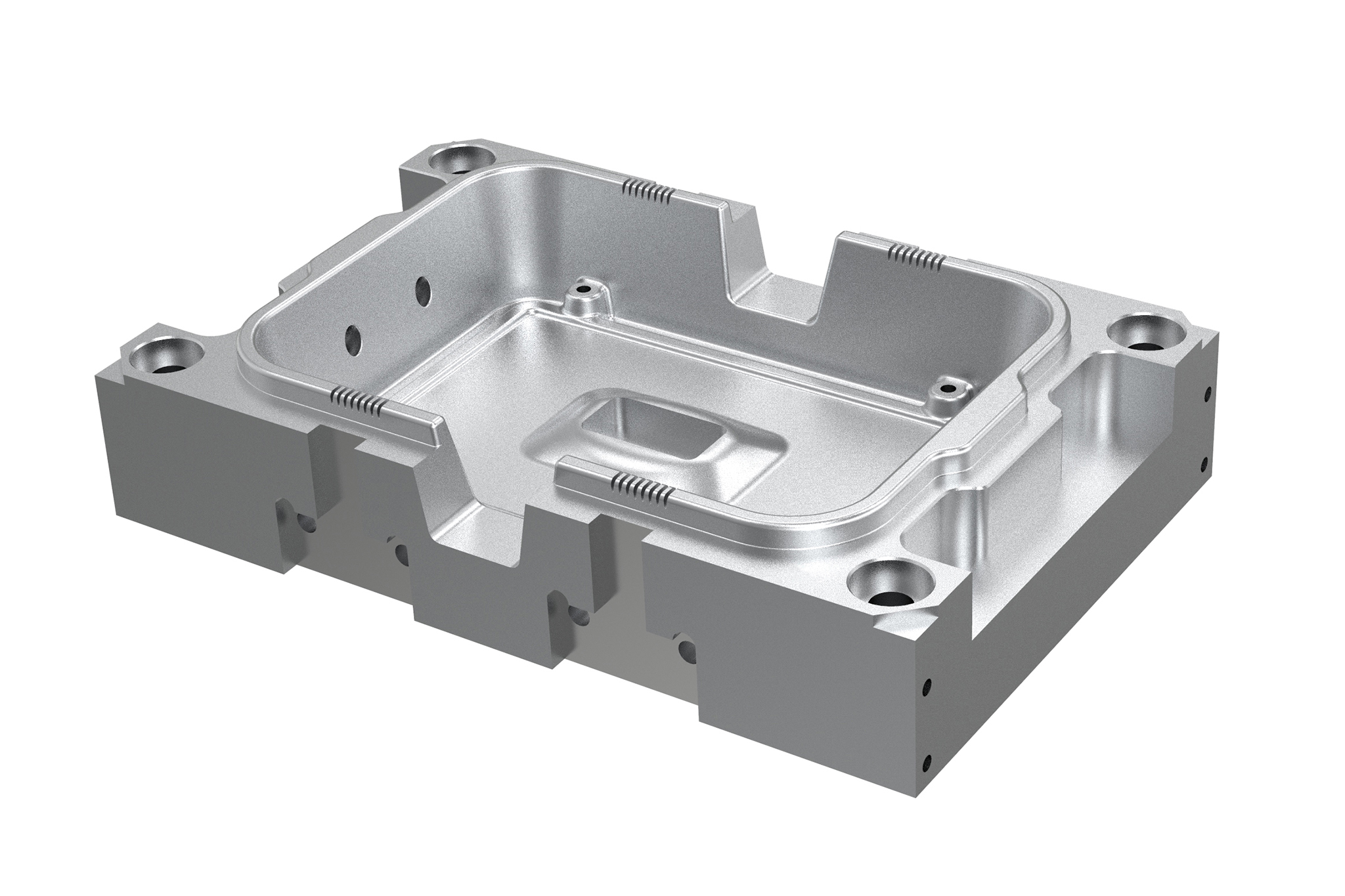

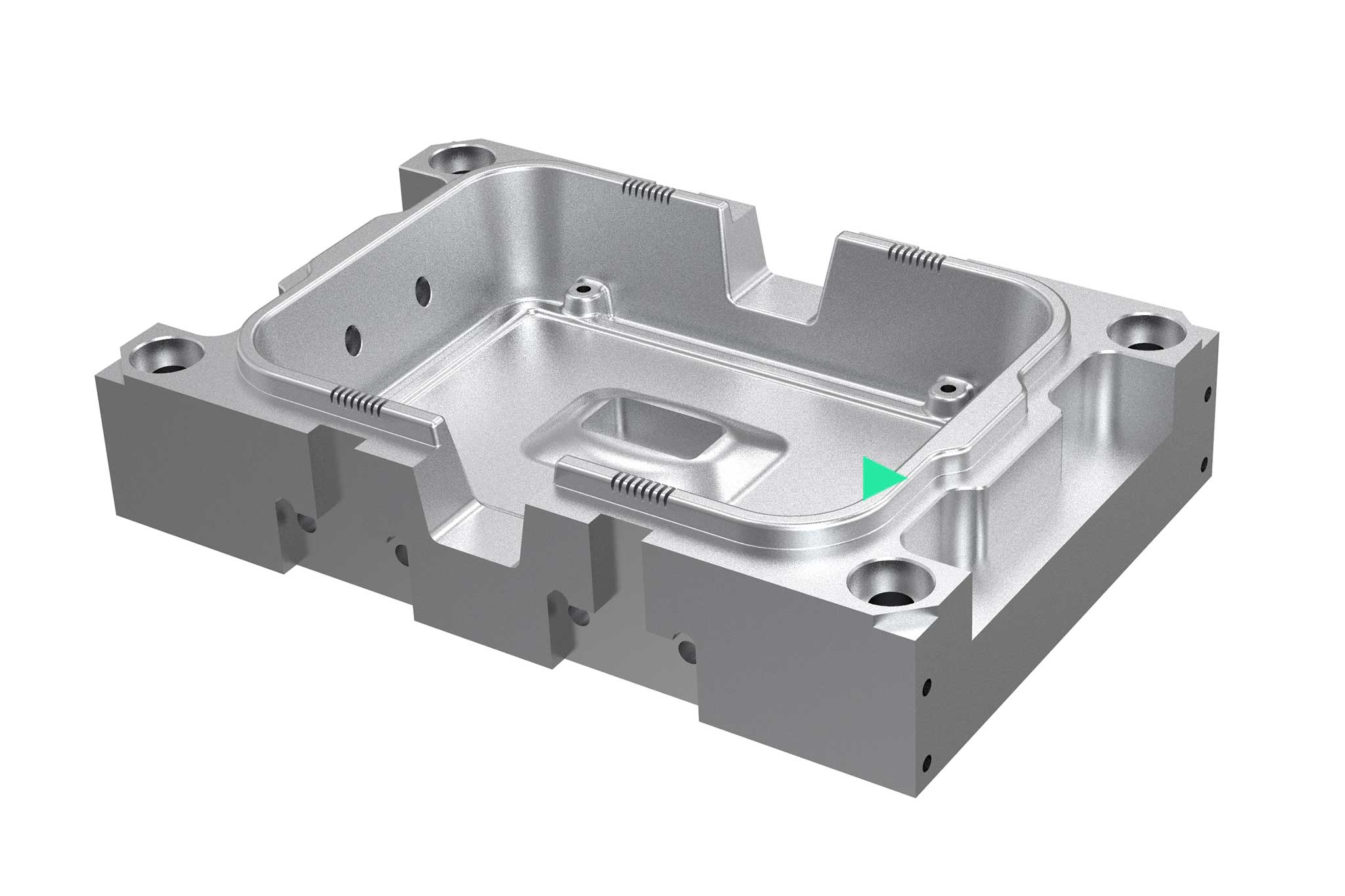

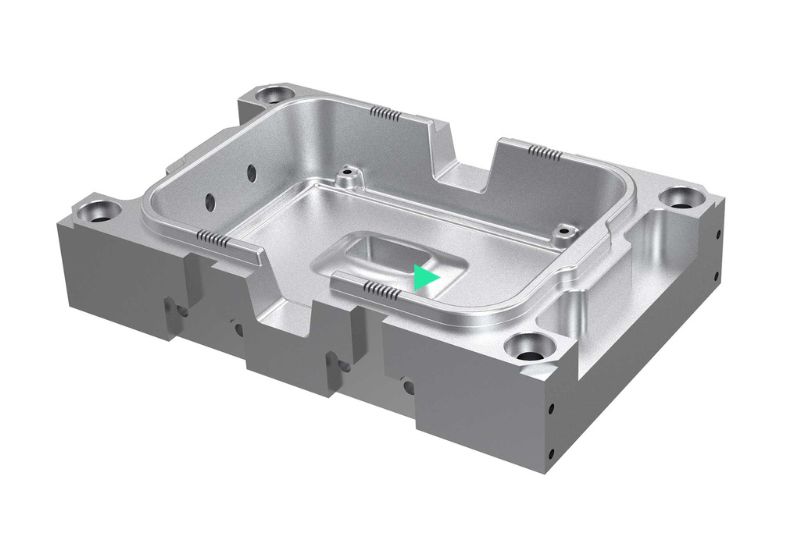

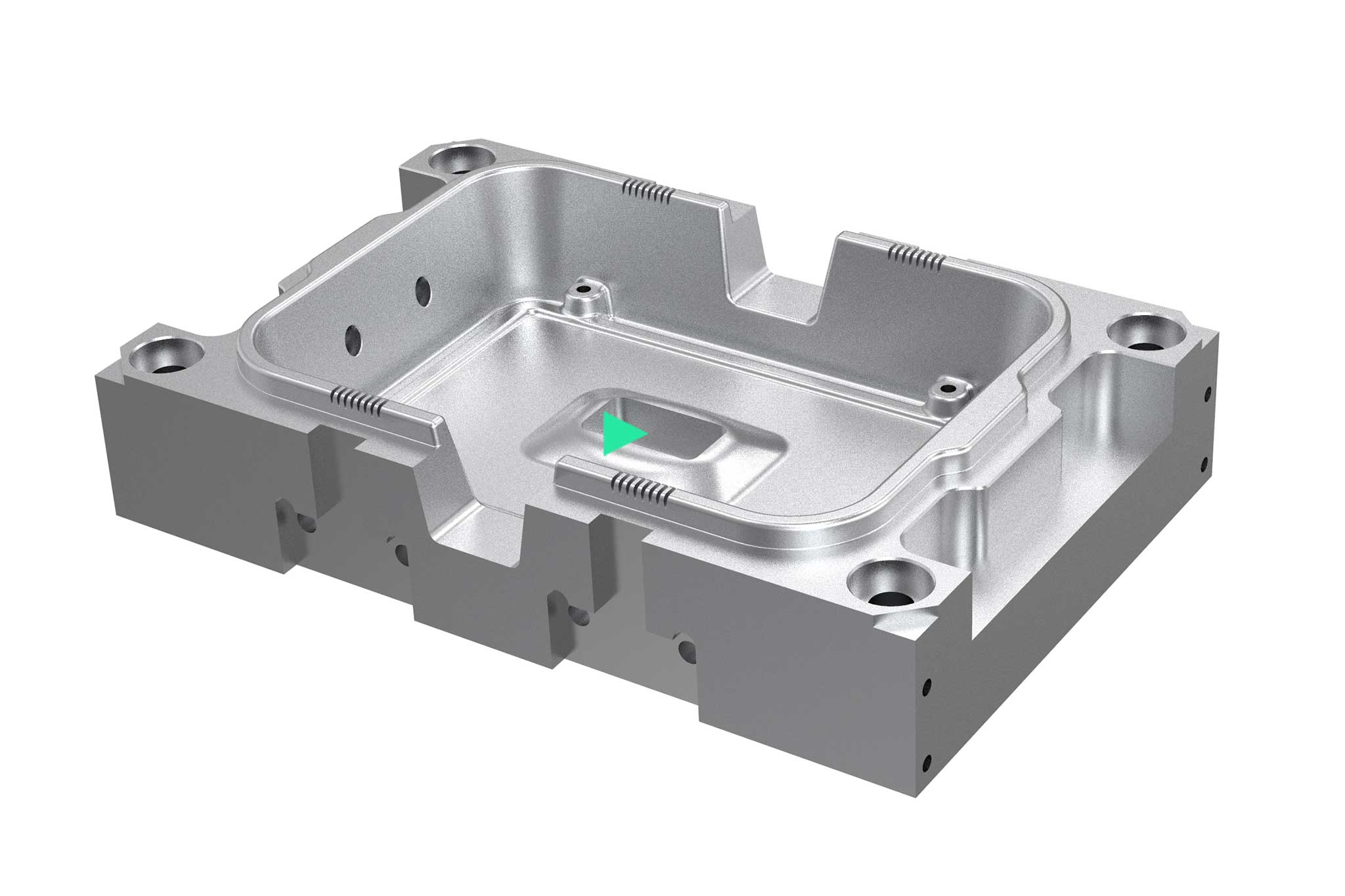

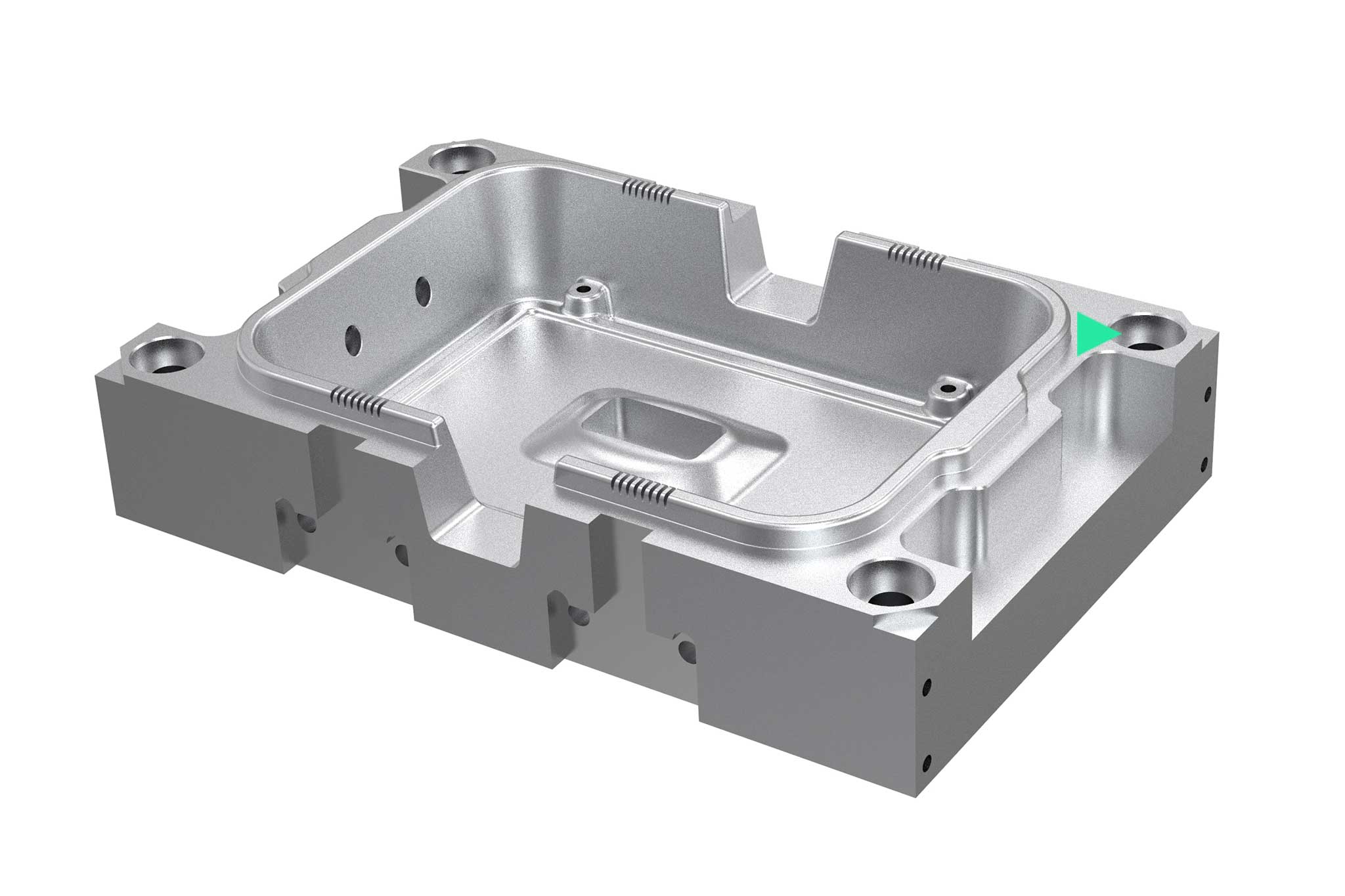

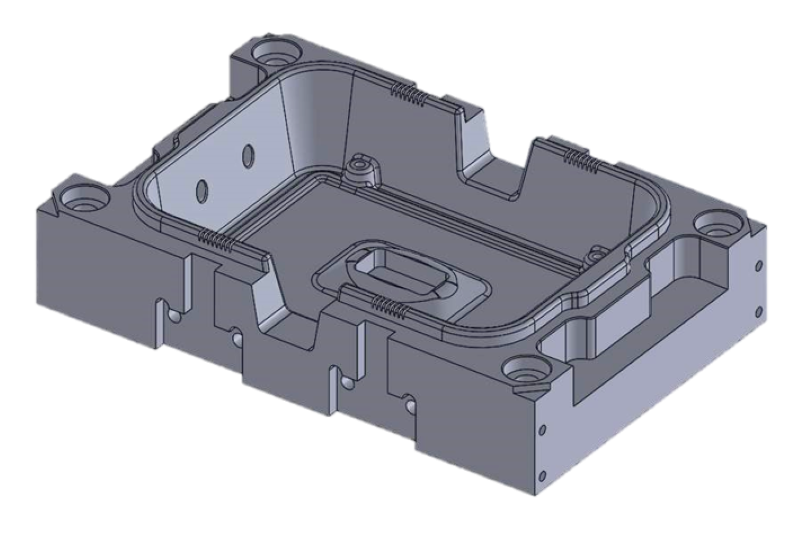

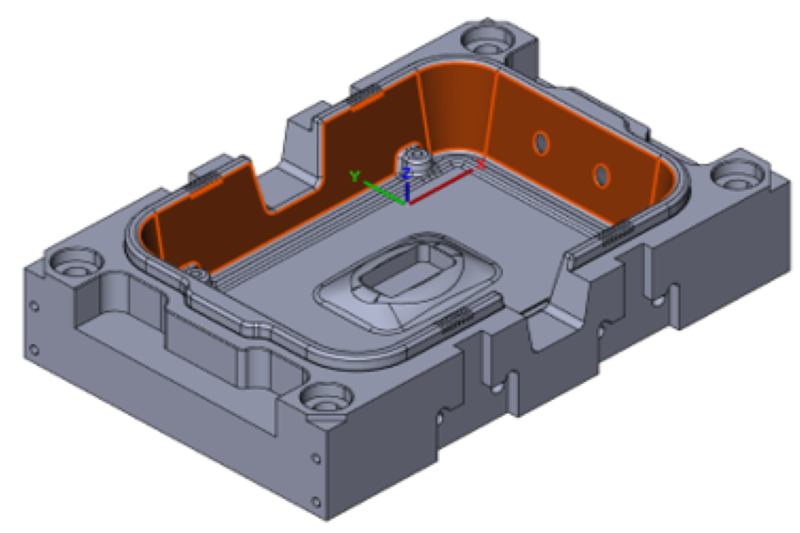

I componenti di crescente complessità e con cavità sempre più profonde, nonché le nervature di stampaggio e di irrigidimento negli stampi per iniezione plastica e pressofusione, rendono necessario l'uso di utensili molto lunghi, anche con diametri di taglio molto ridotti. Le complesse geometrie delle parti e la varietà delle caratteristiche dei materiali, impongono elevate esigenze in termini di lavorazione e di durata dell’utensile.

Esempi di applicazione:

- Stampo per iniezione plastica

- Stampo per pressofusione

- Ghisa

-

Hierro fundido

En la construcción, la ingeniería y la fabricación de herramientas de conformado en frío de tamaño medio y grande se utiliza a menudo hierro fundido debido a las propiedades del material, tales como la resistencia a la presión y la fácil maquinabilidad. En este caso, los componentes principales son las placas de molde y los insertos de molde. MAPAL tiene una gran experiencia en el fresado (2D y 3D) y taladrado (taladrado, escariado, roscado).

Ejemplos de aplicación:

- Placas de molde

- Insertos de molde

- Aluminio

-

Aluminio

Cuando se trata de moldes de series piloto o de prototipos, no es raro que se utilicen materiales fáciles de mecanizar. A menudo se emplean aleaciones de aluminio o ureol (plásticos). En estos casos, las herramientas de metal duro con filos de cuchillas positivas y parcialmente pulidas y las herramientas de PCD aún mejor procuran una elevada productividad y breves tiempos de mecanizado.

Ejemplos de aplicación:

- Moldes de serie previa

- Moldes de prototipos

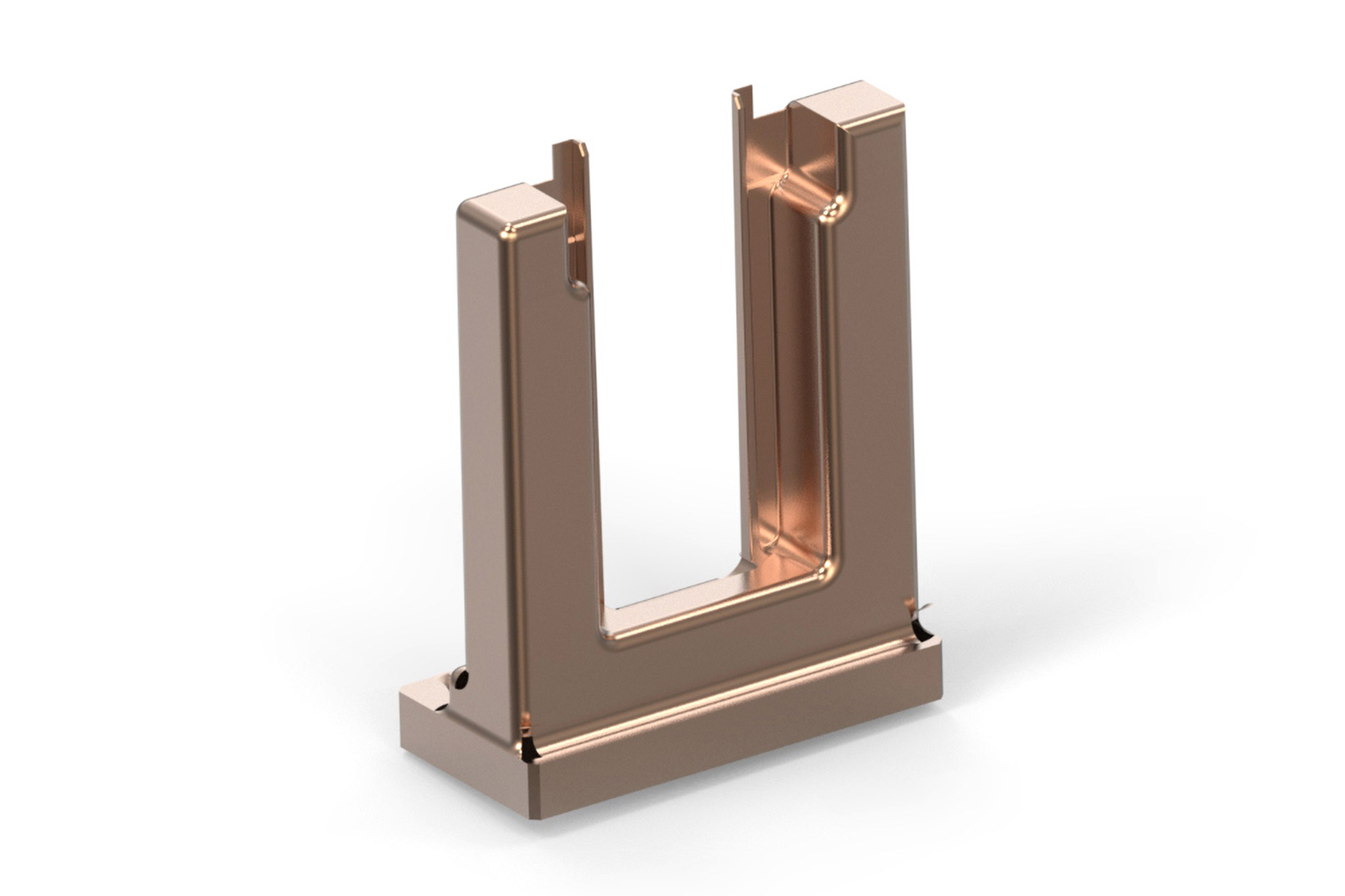

- Cobre

-

Cobre

La fabricación de electrodos para procesos de gestión de datos energéticos requiere mecanizar aleaciones de cobre y materiales de grafito. La elección del material de los electrodos se rige por los requisitos del molde que se debe fabricar. Las aleaciones de cobre son relativamente caras y, en general, se utilizan para el mecanizado final en los electrodos cuando se trata de una elevada calidad de superficie y precisión de moldeo. Las fresas de metal duro con geometrías especiales de MAPAL garantizan aquí unos resultados de mecanizado muy precisos.

Ejemplo de aplicación:

- Electrodos para electroerosión (procesos EDM)

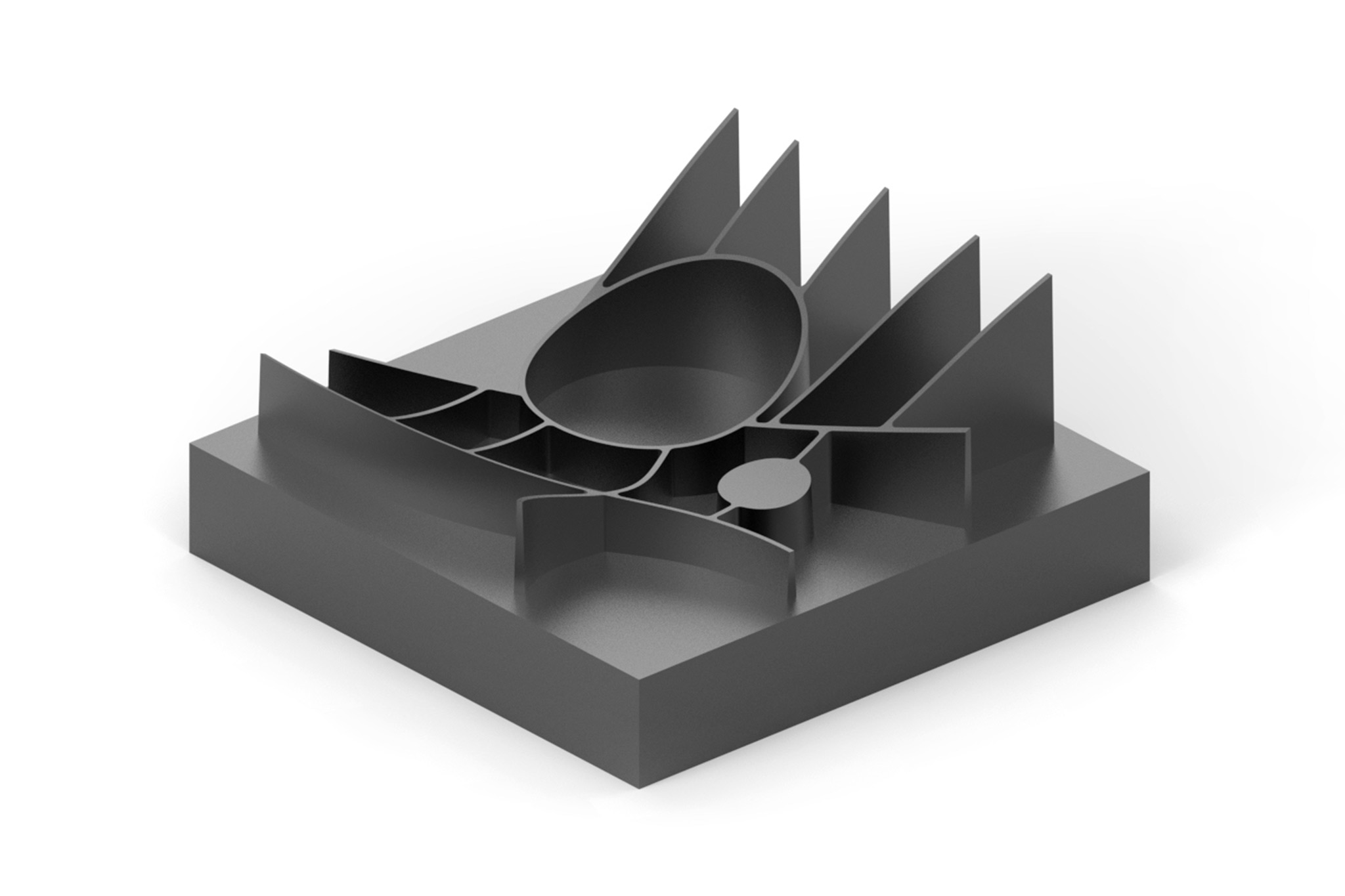

- Grafito

-

Grafito

El grafito tiene un efecto muy abrasivo sobre la herramienta y genera un gran desgaste en el filo de la cuchilla. El aumento del desgaste tiende a reventar los perfiles que se mecanizan. Por esta razón se requiere una herramienta con la geometría adecuada y el material de corte óptimo. Para el mecanizado de grafito MAPAL utiliza herramientas de metal duro con recubrimiento de diamante o herramientas de PCD.

Ejemplo de aplicación:

- Electrodos para electroerosión (procesos EDM)

De la pieza sin tratar a la pieza terminada

-

1 / 8

Superficies en 2D

En esta categoría se incluyen los procesos de mecanizado ejecutados directamente en la máquina como el fresado plano, fresado de cajeras y paredes rectas. También el trabajo en geometrías complejas que se pueden programar con un software CAM.

Acerca de la gama de productos del mecanizado de superficies en 2D -

2 / 8

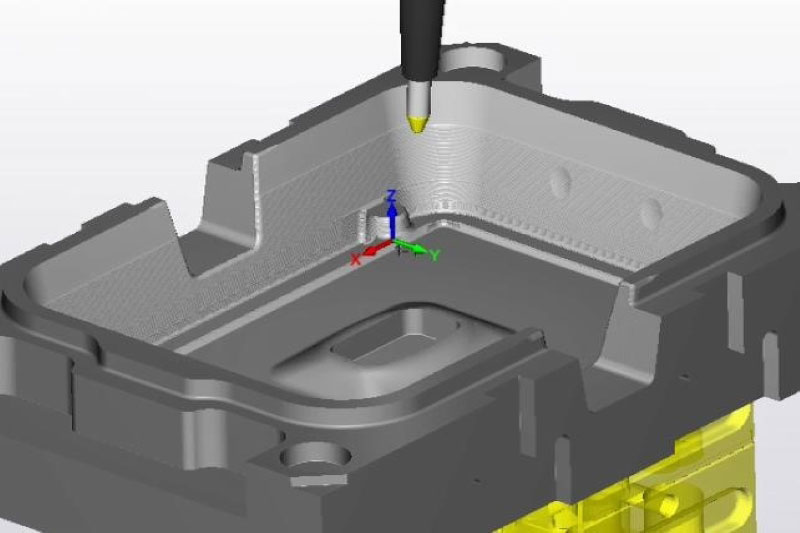

Superficies en 3D

En los sectores de la fabricación de moldes y troqueles, los moldes complejos forman parte del día a día. El desarrollo continuo de las máquinas-herramienta y del software CAM mantienen en aumento el nivel del rendimiento y la productividad. Por eso, las herramientas usadas también deben cumplir siempre los requisitos de la última generación. Para alcanzar los mejores resultados, hay que analizar el proceso al comienzo del diseño.

Acerca de la gama de productos del mecanizado de superficies en 3D -

3 / 8

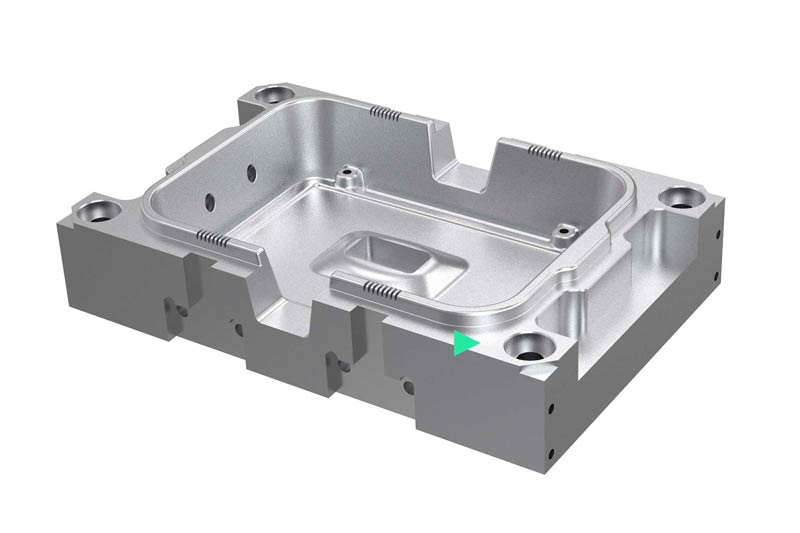

Cajeras abiertas

Los insertos de molde representan también las tareas de mecanizado necesarias para el moldeo o diversos componentes. Cada vez más, los usuarios mecanizan las cajeras abiertas (mecanizado de volumen) con fresado trocoidal. Este sistema de mecanizado facilita que se mejoren los tiempos de mecanizado y prolonguen la duración de la herramienta.

Acerca de la gama de productos del mecanizado de cajeras abiertas -

4 / 8

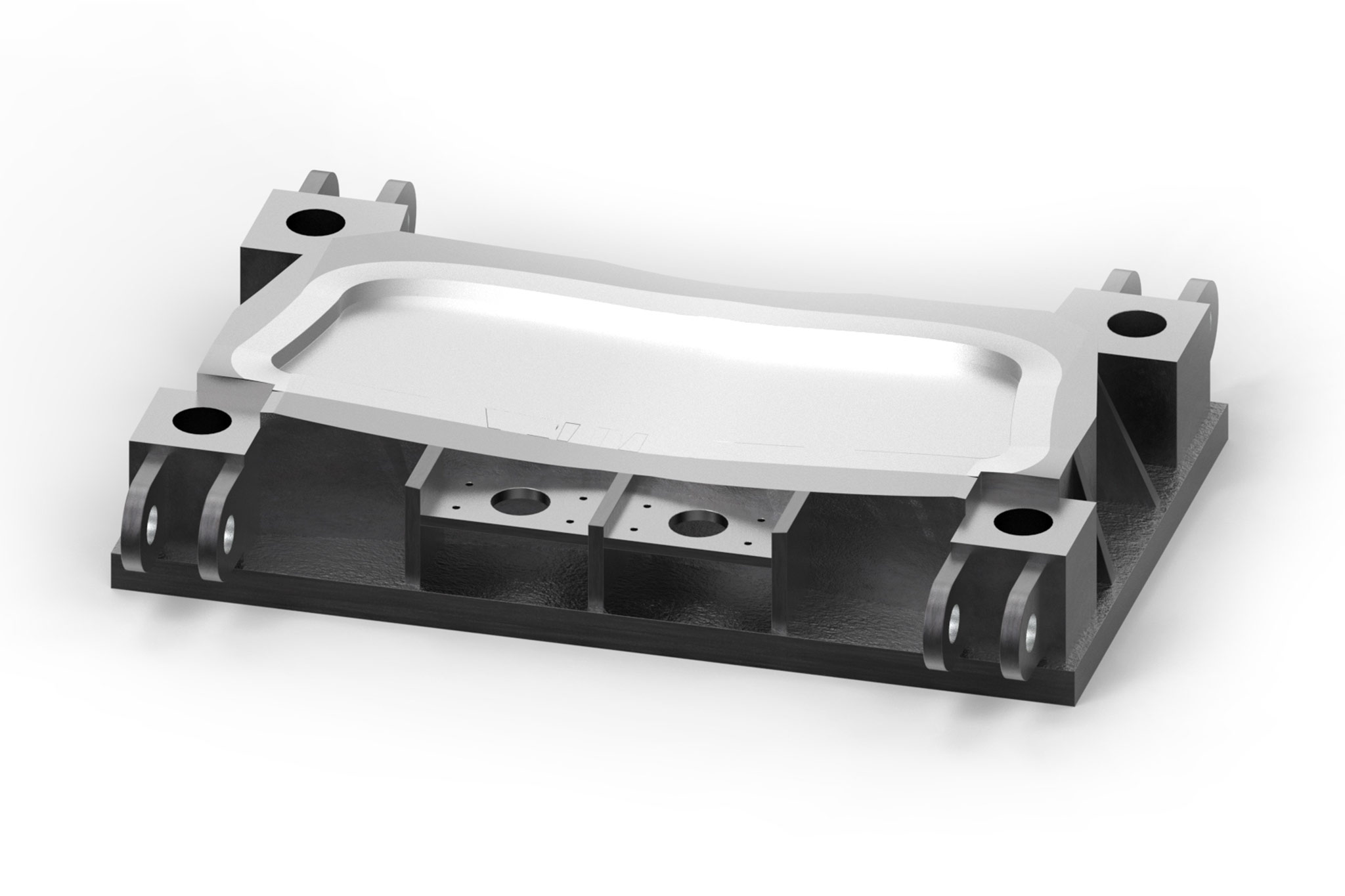

Cajeras cerradas

Las cajeras cerradas suelen fabricarse con desbastado a escala Z. Normalmente, se elige para ello el fresado de la entrada de mecanizado por medio de una rampa. La elección de la herramienta dependerá del grosor de las paredes y de la inclinación de moldeado del componente. La amplia gama de MAPAL de sistemas modulares también abarca el mecanizado de cajeras profundas de gran diámetro.

Acerca de la gama de productos del mecanizado de cajeras cerradas -

5 / 8

Fresado helicoidal

Uno de los puntos importantes de los mecanizados de fresado es reducir el tiempo de mecanizado. Normalmente, con formas de herramienta específicas para el mecanizado se consigue eliminar el proceso de taladrado previo de las cajeras cerradas y redondas. En el fresado helicoidal se programan trayectorias de fresado con entradas helicoidales adecuadas para las dimensiones de las cajeras.

Acerca de la gama de productos de fresado helicoidal -

6 / 8

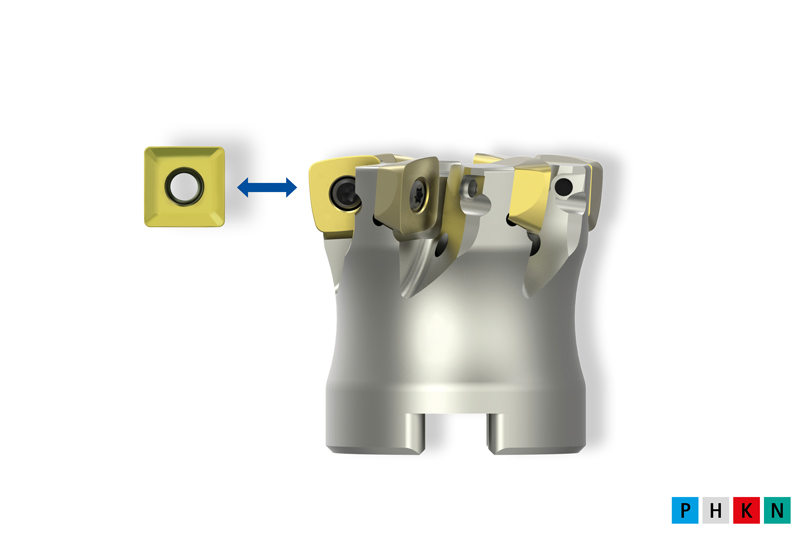

Superficies planas

Tratar de lograr superficies planas es muy habitual en los distintos campos de la fabricación de moldes y troqueles: ya sea porque lo requiere el componente, la estrategia por medio del mecanizado de fresado correspondiente o por medio de los requisitos de superficies de cierre de molde, así como secciones y troquelados. Por tanto, la herramienta adecuada se elegirá en función del uso y de los requisitos.

Acerca de la gama de productos del mecanizado de superficies planas -

7 / 8

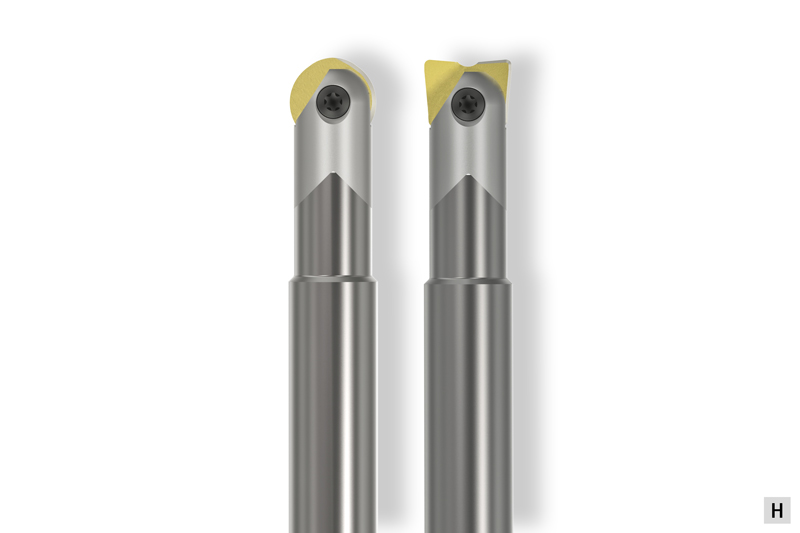

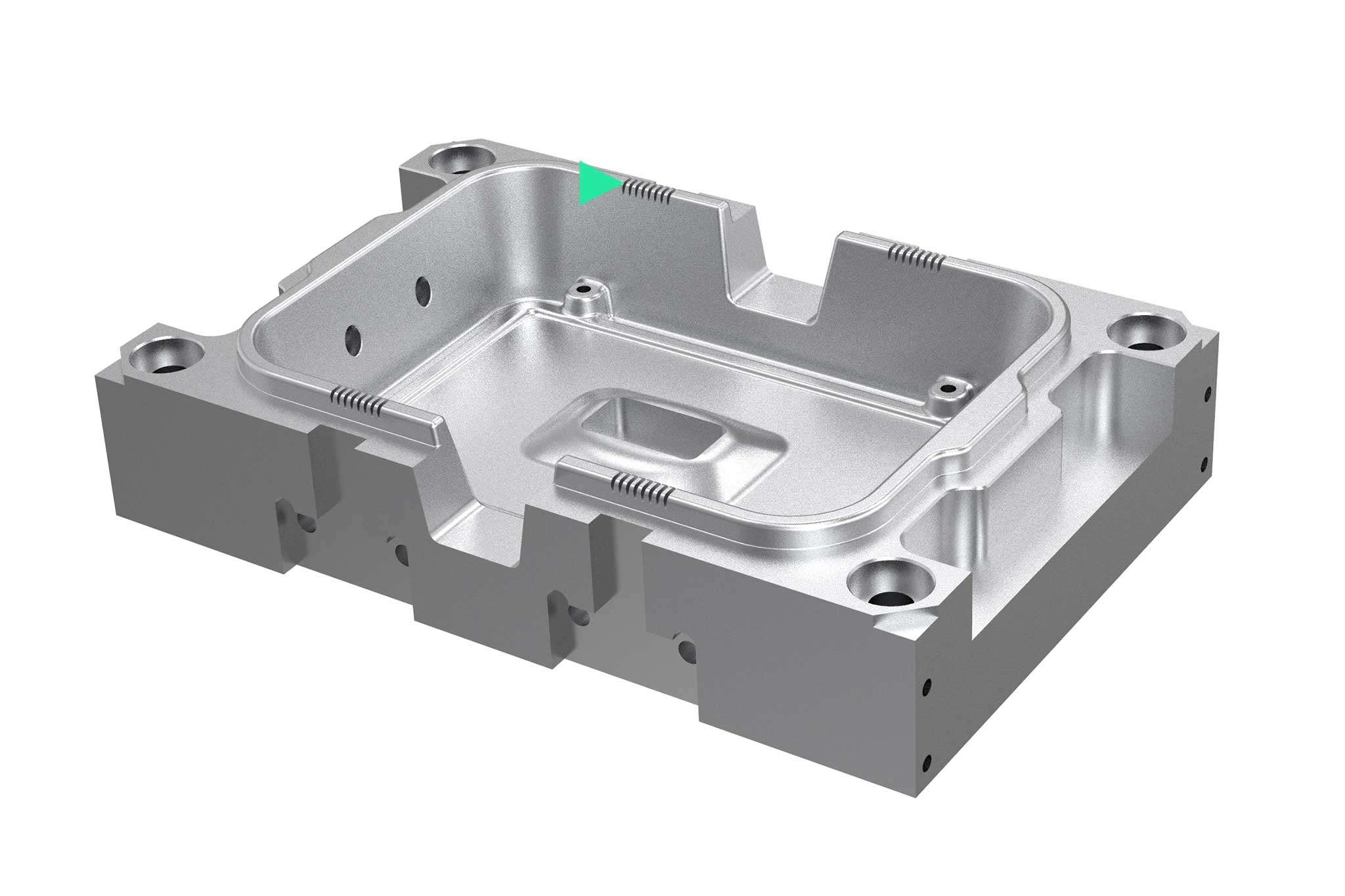

Paredes finas y nervaduras

Los moldes de plástico por inyección y los moldes de fundición de presión suelen tener nervaduras y paredes finas. Por ejemplo, cada vez se fresan más nervaduras, porque dicho proceso es más rentable que el proceso EDM (electroerosión). Por norma general, se usan herramientas de metal duro largas o extralargas de diámetro pequeño. En estos casos, también se pueden emplear las soluciones específicas de cada cliente (RibCutter) correspondientes a la forma de la nervadura.

Acerca de la gama de productos del mecanizado de paredes y nervaduras finas -

8 / 8

Agujeros pequeños y grandes

En los sectores de la fabricación de moldes y troqueles hay infinidad de procesos de taladrado en macizo: Por ejemplo, grandes perforaciones en columnas guía, perforaciones profundas para sistemas de refrigeración o perforaciones de gran precisión para pasadores expulsores. Para cada uno de los pasos de fabricación, MAPAL ofrece una amplia variedad de herramientas de taladrado y escariado.

Acerca de la gama de productos del mecanizado de agujeros pequeños y grandes

Todo de un solo proveedor

Engineering Workflow - From theory to practice

Further items about the die&mould area

-

02.12.2025

Large tool package for Mangner Zerspanungstechnik

MAPAL has equipped Mangner GmbH with a comprehensive tool package for drilling operations.

-

04.03.2025

CORMOL relies on milling cutters such as the OptiMill-3D-HF from MAPAL for tool making

CORMOL from Portugal manufactures stamping tools, for which it has been working closely with MAPAL since 2022. With the OptiMill-3D-HF, CORMOL has found a reliable and economical tool solution.

#Products #Industries #CaseStudies #Technology #Die&Mould #Milling

-

25.06.2024

Efficient production in die and mould making: Krämer+Grebe and MAPAL

The mouldmaking company Krämer+Grebe optimises production with MAPAL reamers and milling cutters and ensures process reliability in international competition.

#CaseStudies #Products #Industries #Reaming&FineBoring #Milling #Die&Mould

Our retail partners

Responsibility according to postcode areas

-

1 / 16

Postcode 35

FRITZ WEG GmbH & Co. KG

Ahornweg 41

35713 Eschenburg-WissenbachPhone: +49 2774 701-0

Fax: +49 2774 701-39

Email: info@fritzweg.de

Web: www.fritzweg.de -

2 / 16

Postcode 44

Jansen Schneidwerkzeuge Vertriebs GmbH

Im Käsebrink 12

58840 PlettenbergPhone: +49 2391 9177-0

Fax: +49 2391 9177-20

Email: info@j-s-v.com

Web: www.j-s-v.com -

3 / 16

Postcode 51

Jansen Schneidwerkzeuge Vertriebs GmbH

Im Käsebrink 12

58840 PlettenbergPhone: +49 2391 9177-0

Fax: +49 2391 9177-20

Email: info@j-s-v.com

Web: www.j-s-v.com -

4 / 16

Postcode 56, 57

FRITZ WEG GmbH & Co. KG

Ahornweg 41

35713 Eschenburg-WissenbachPhone: +49 2774 701-0

Fax: +49 2774 701-39

Email: info@fritzweg.de

Web: www.fritzweg.de -

5 / 16

Postcode 58, 59

Jansen Schneidwerkzeuge Vertriebs GmbH

Im Käsebrink 12

58840 PlettenbergPhone: +49 2391 9177-0

Fax: +49 2391 9177-20

Email: info@j-s-v.com

Web: www.j-s-v.com -

6 / 16

Postcode 60, 61

Heinrich Meier GmbH

Herrenwaag 31

75417 MühlackerPhone: +49 7041 9530-0

Fax: +49 7041 9530-30

Email: info@heinrich-meier.de

Web: www.heinrich-meier.de -

7 / 16

Postcode 63 - 69

Heinrich Meier GmbH

Herrenwaag 31

75417 MühlackerPhone: +49 7041 9530-0

Fax: +49 7041 9530-30

Email: info@heinrich-meier.de

Web: www.heinrich-meier.de -

8 / 16

Postcode 70 - 73

Dieter Schätzle GmbH & Co. KG

Präzisionswerkzeuge

Unter Haßlen 12

78532 TuttlingenPhone: +49 7462 9465-0

Fax: +49 7462 9465-50

Email: info@schaetzle-werkzeuge.de

Web: www.schaetzle-werkzeuge.de -

9 / 16

Postcode 74, 75

Heinrich Meier GmbH

Herrenwaag 31

75417 MühlackerPhone: +49 7041 9530-0

Fax: +49 7041 9530-30

Email: info@heinrich-meier.de

Web: www.heinrich-meier.de -

10 / 16

Postcode 76 - 79

Dieter Schätzle GmbH & Co. KG

Präzisionswerkzeuge

Unter Haßlen 12

78532 TuttlingenPhone: +49 7462 9465-0

Fax: +49 7462 9465-50

Email: info@schaetzle-werkzeuge.de

Web: www.schaetzle-werkzeuge.de -

11 / 16

Postcode 80 - 87

AB1-Tools e.K.

Goethering 45

91732 MerkendorfPhone: +49 9826 333-2241

Fax: +49 9826 333-3691

Email: info@ab1-tools.com

Web: www.ab1-tools.com -

12 / 16

Postcode 88, 89

Dieter Schätzle GmbH & Co. KG

Präzisionswerkzeuge

Unter Haßlen 12

78532 TuttlingenPhone: +49 7462 9465-0

Fax: +49 7462 9465-50

Email: info@schaetzle-werkzeuge.de

Web: www.schaetzle-werkzeuge.de -

13 / 16

Postcode 90 - 97

AB1-Tools e.K.

Goethering 45

91732 MerkendorfPhone: +49 9826 333-2241

Fax: +49 9826 333-3691

Email: info@ab1-tools.com

Web: www.ab1-tools.com -

14 / 16

Danmark

EDECO TOOL APS

Naverland 2

2600 Glostrup

DanmarkPhone: +45 7060 2029

Email: info@edeco.dk

Web: www.edeco.dk -

15 / 16

Italy

TEKNOS S.r.l.

Via A. Pigafetta, 2

35011 Campodarsego (PD)

ItaliaPhone: +39 049 8877061

Email: info@teknositalia.it

Web: www.teknositalia.it -

16 / 16

Portugal

Álamo-Ferramentas Unipessoal Lda

Rua da ETAR, Lote 9

Zona Industrial de Oiã

3770-059 Oiã

Phone: +351 234 728-193

Email: geral@alamo-ferramentas.com