Competênvia em perfuração total, alargar e rebaixar

Partindo da ênfase na fabricação de ferramentas especiais para soluções de usinagem específicas para o cliente, a MAPAL desenvolveu um abrangente programa padrão para perfuração total, alargamento e rebaixamento.

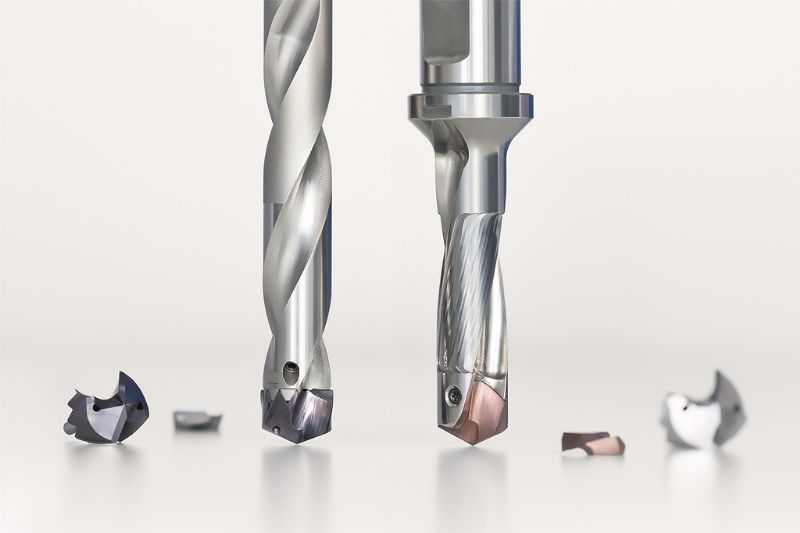

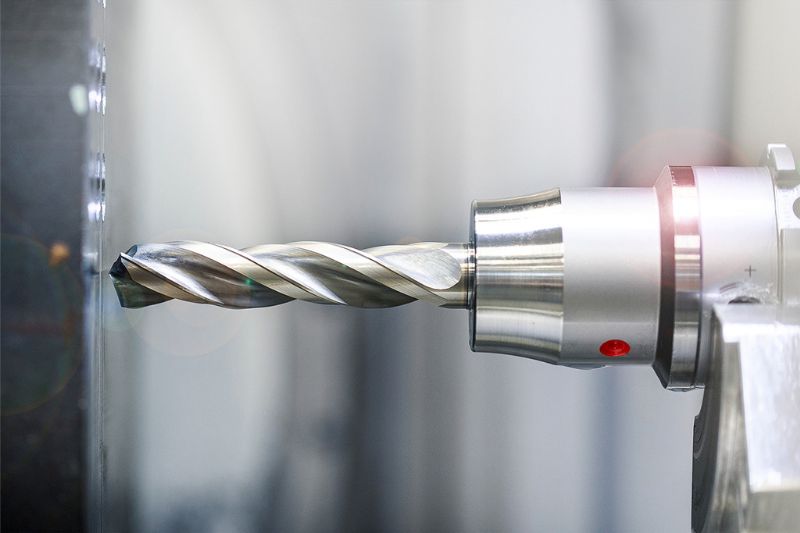

在采用整体硬质合金刀具钻孔加工领域,MAPAL 是全球领军企业之一。整体硬质合金钻头产品包括用于对几乎所有材料进行流程安全且经济型加工的解决方案,再加上进行高经济性加工的现代化可换头系统,进一步扩展了产品范围。

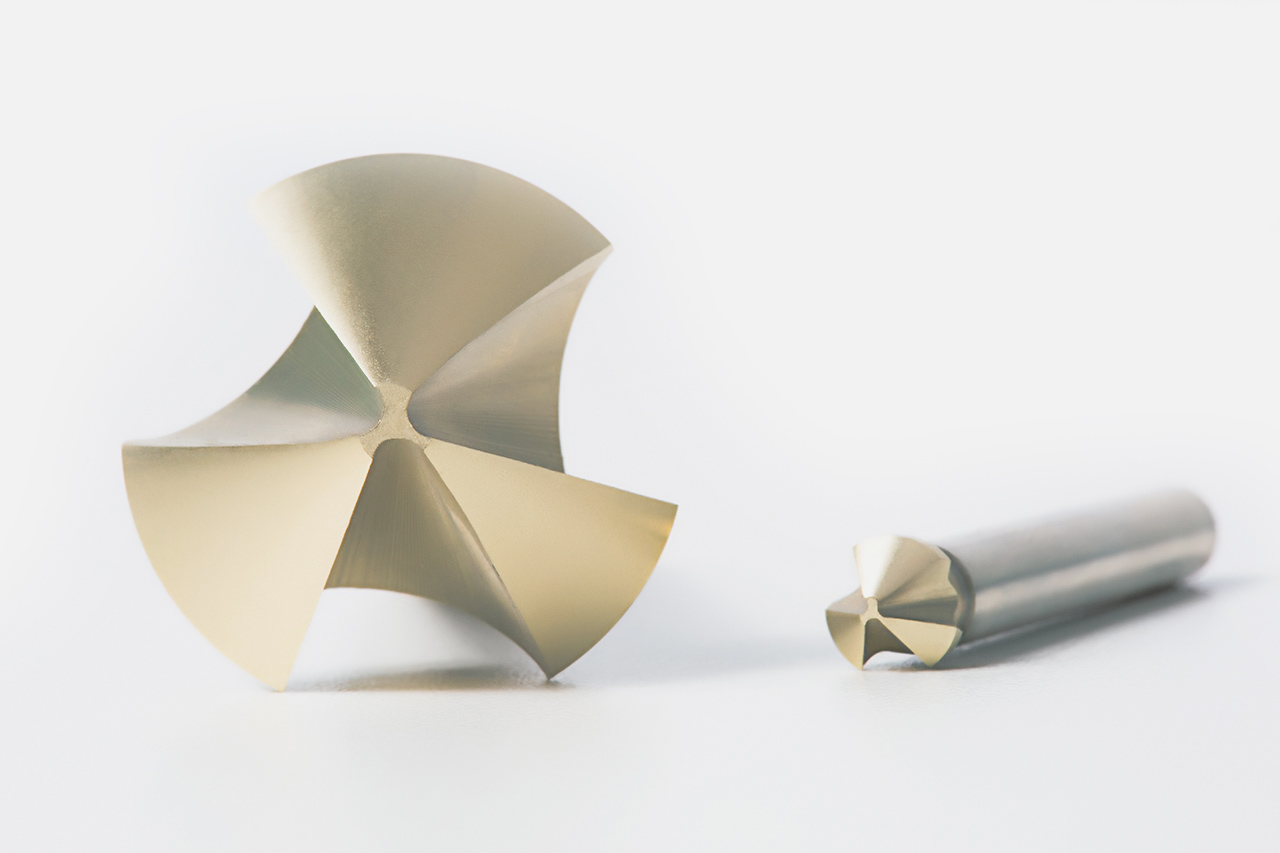

配置 ISO 可转位刀片的刀具在镗孔领域稳固地占领了领军的地位。以精密加工的专门知识为基础,MAPAL 为这种加工开发了大量的标准刀具。对于客户定制的解决方案,PCD 整体钻头可以针对流程进行最佳的设计。螺旋式刀具具有极高的性能和特别短的加工时间。

对于二级加工,例如锪孔,MAPAL 也提供有最佳的解决方案 - 无论是采用为这种加工所设计的独立的锪孔刀具,还是采用与钻孔刀具组合在一起的锪孔台阶。

MAPAL 集团统一的标准流程和遍布世界的大量的生产基地保证了最佳的刀具供给,以及用同样的高质量对整体硬质合金刀具和 PCD 刀具进行修磨。

配置 ISO 可转位刀片的刀具在镗孔领域稳固地占领了领军的地位。以精密加工的专门知识为基础,MAPAL 为这种加工开发了大量的标准刀具。对于客户定制的解决方案,PCD 整体钻头可以针对流程进行最佳的设计。螺旋式刀具具有极高的性能和特别短的加工时间。

对于二级加工,例如锪孔,MAPAL 也提供有最佳的解决方案 - 无论是采用为这种加工所设计的独立的锪孔刀具,还是采用与钻孔刀具组合在一起的锪孔台阶。

MAPAL 集团统一的标准流程和遍布世界的大量的生产基地保证了最佳的刀具供给,以及用同样的高质量对整体硬质合金刀具和 PCD 刀具进行修磨。