Competenza nell'alesatura

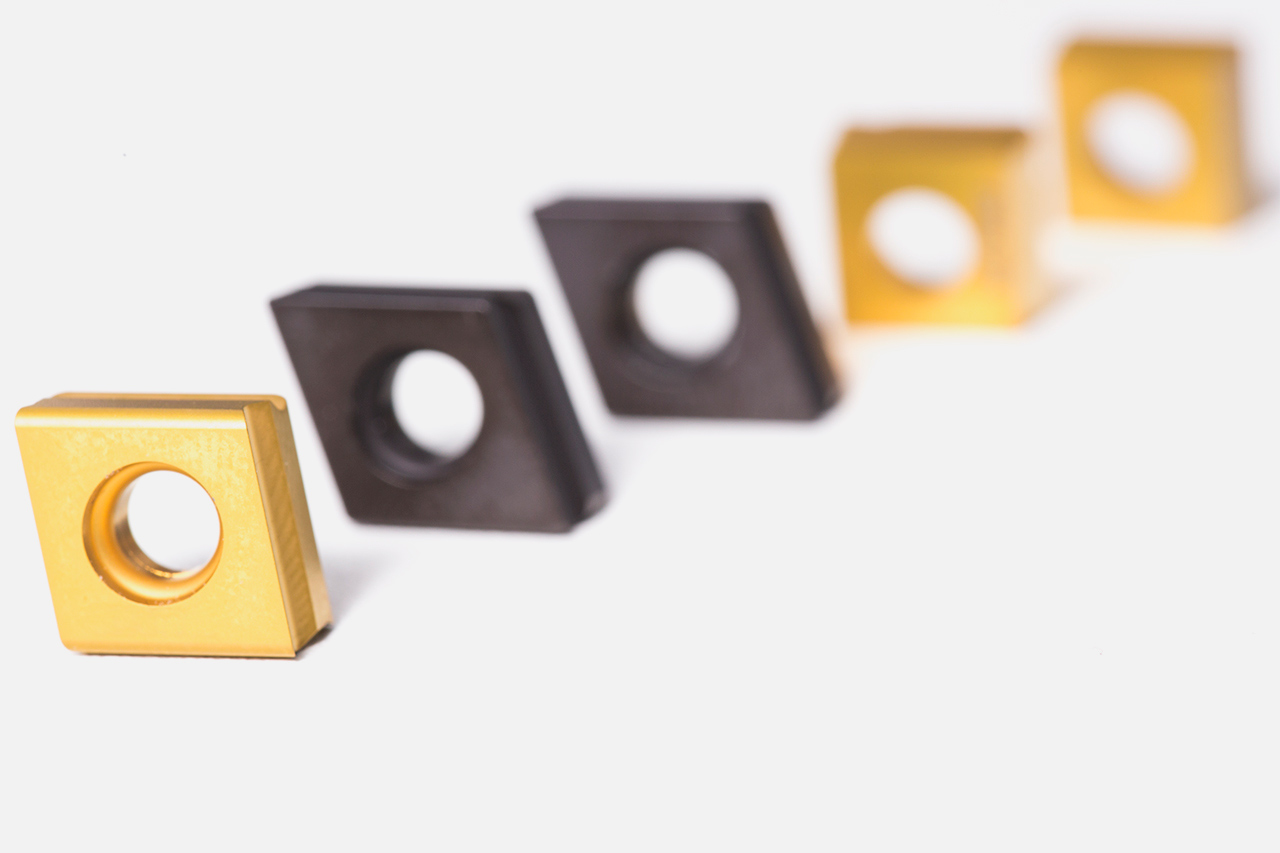

Gli utensili di alesatura MAPAL diventano utensili estremamente potenti grazie ad una produzione che abbina tecnologie innovative e una precisione assoluta. L'approfondita conoscenza dell'intero processo di truciolatura e la comprensione dello svolgimento della produzione nel suo insieme consentono dei progressi concreti.

La perfetta sinergia di tutti i componenti coinvolti in un processo di truciolatura si traduce nella massima convenienza e in una produzione attenta al risparmio delle risorse. In questo senso è particolarmente importante avere a disposizione, fin dalla fase di progettazione del processo, una vasta conoscenza di tutte le procedure di truciolatura, nonché avanzate

tecnologie di lavorazione.

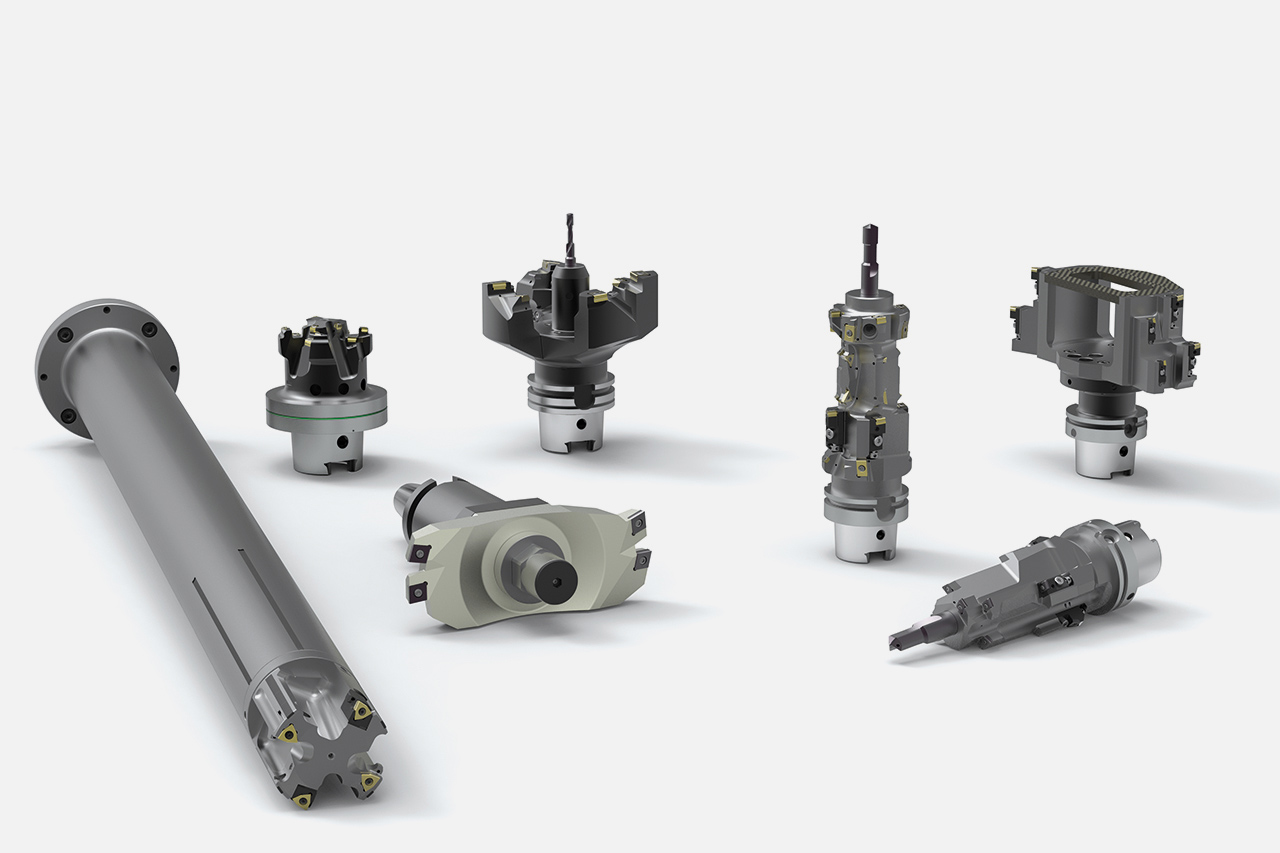

Grazie alla preziosa esperienza dei suoi progettisti e alla vasta gamma di utensili innovativi e potenti, MAPAL offre la base di partenza ideale. A seconda delle necessità specifiche, l'azienda è in grado di ricorrere a tutte le tecnologie utensili disponibili. Il risultato sono soluzioni di truciolatura che non scendono mai a compromessi.

tecnologie di lavorazione.

Grazie alla preziosa esperienza dei suoi progettisti e alla vasta gamma di utensili innovativi e potenti, MAPAL offre la base di partenza ideale. A seconda delle necessità specifiche, l'azienda è in grado di ricorrere a tutte le tecnologie utensili disponibili. Il risultato sono soluzioni di truciolatura che non scendono mai a compromessi.