Drilling, Boring and Countersinking Comptence

Starting from the focus on the manufacture of custom tools for customer-specific machining solutions, MAPAL has developed a comprehensive standard programme for drilling, boring and countersinking.

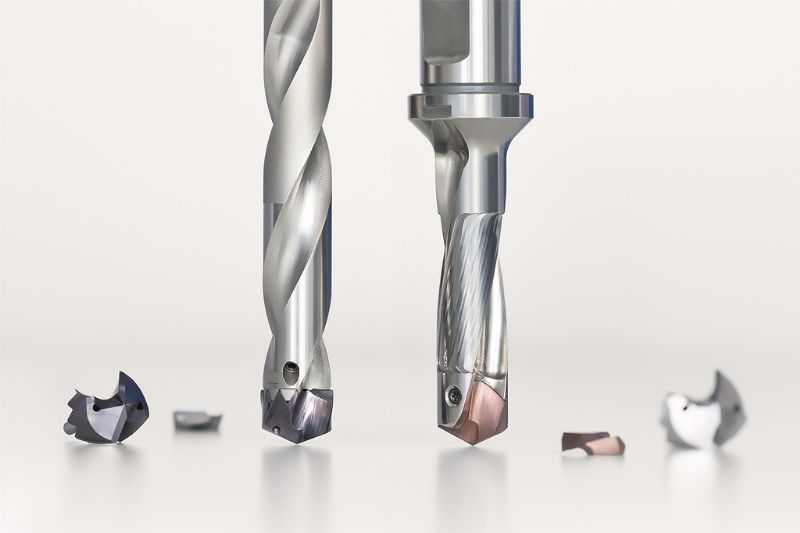

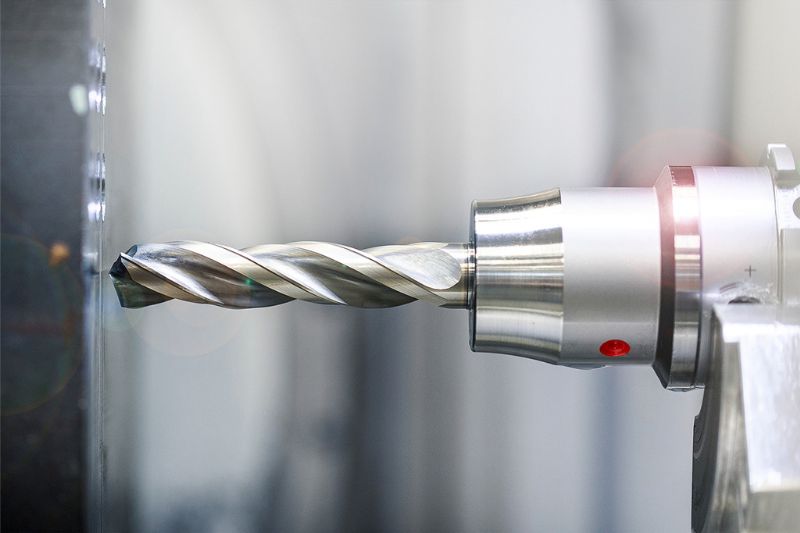

In the area of drilling using solid carbide tools, MAPAL is one of the world's largest providers. The programme of solid carbide drills covers solutions for the reliable and cost-effective machining of almost every workpiece material and is completed by modern replaceable head systems for the highest cost-effectiveness.

Tools with ISO indexable inserts are taking a leading role in the area of boring. Building on its know-how related to fine machining, MAPAL has developed a comprehensive standard programme for this machining.

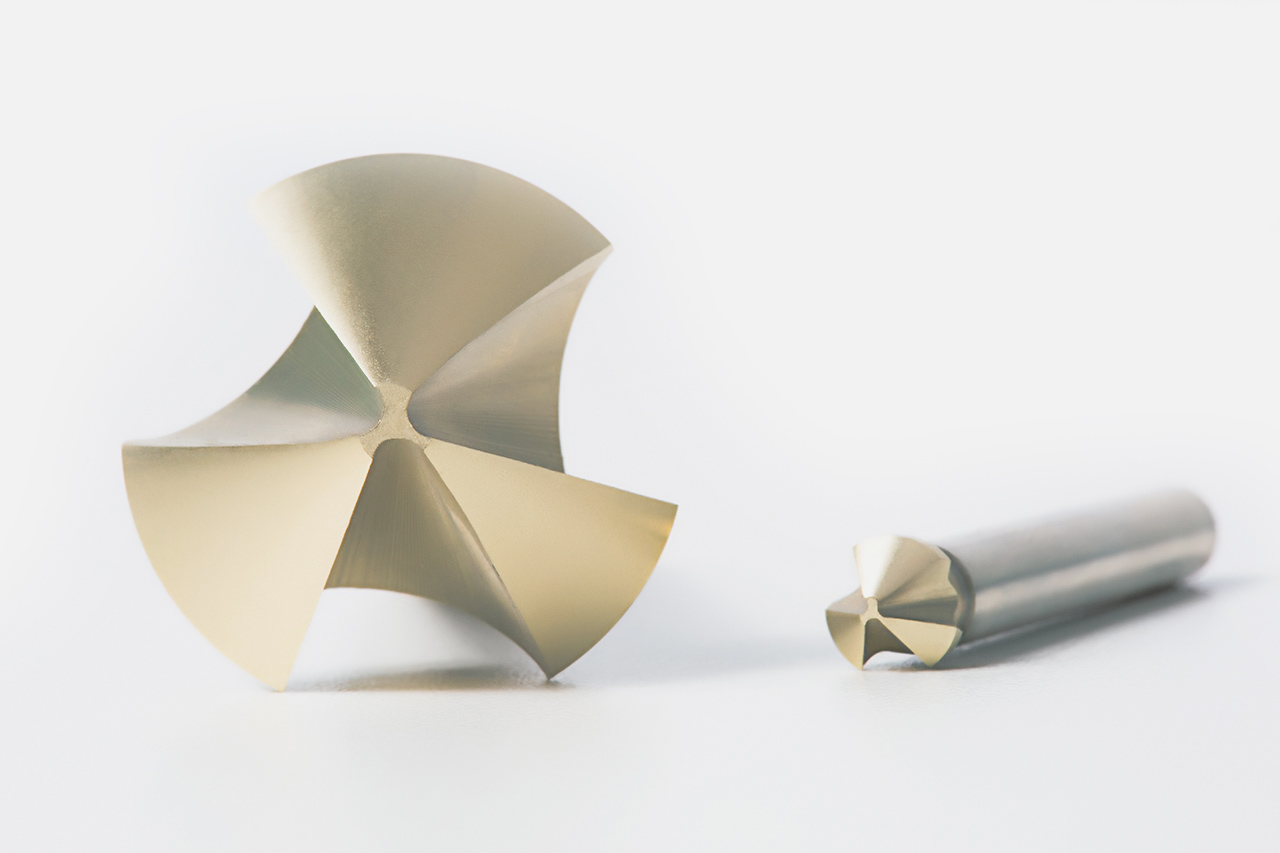

PCD drills can be optimally matched to the process for customer-specific solutions. Twisted designs ensure the highest performance and extremely reduced machining times.

MAPAL also offers the optimal solution for secondary machining operations such as countersinking – whether using the tool specifically designed for this machining or in combination with the drilling tool as a countersink step.

Standardised processes and numerous MAPAL Group sites worldwide ensure optimum tool supply and re-grinding for solid carbide and PCD tools with the same high quality.

Tools with ISO indexable inserts are taking a leading role in the area of boring. Building on its know-how related to fine machining, MAPAL has developed a comprehensive standard programme for this machining.

PCD drills can be optimally matched to the process for customer-specific solutions. Twisted designs ensure the highest performance and extremely reduced machining times.

MAPAL also offers the optimal solution for secondary machining operations such as countersinking – whether using the tool specifically designed for this machining or in combination with the drilling tool as a countersink step.

Standardised processes and numerous MAPAL Group sites worldwide ensure optimum tool supply and re-grinding for solid carbide and PCD tools with the same high quality.