Soluções de usinagem para a mobilidade elétrica

A mobilidade está em transformação. A meta é um futuro com zero emissão de CO2

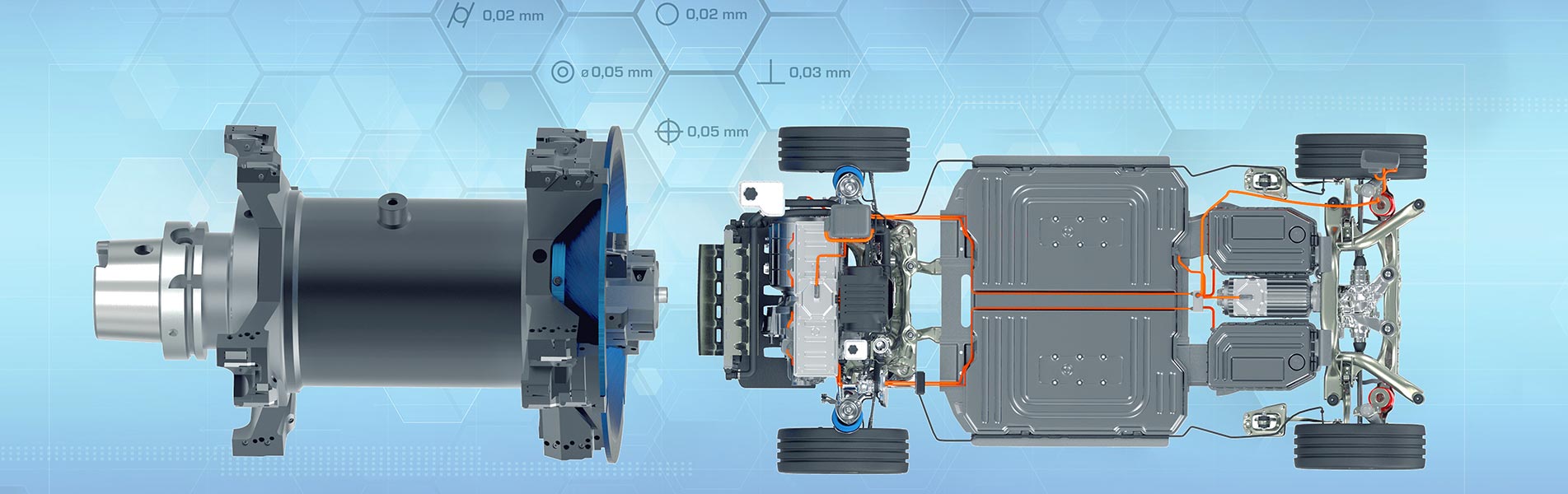

A mobilidade está em transformação e tem foco em um futuro neutro em termos de CO2 e na sustentabilidade. Para atingir este objetivo, a indústria automotiva está trabalhando em conceitos de propulsão alternativos. O acionamento elétrico está substituindo cada vez mais o motor de combustão. No entanto, essa mudança não acontecerá da noite para o dia. Estão sendo desenvolvidos alguns componentes do acionamento convencional e a participação dos acionamentos híbridos está aumentando. Concomitantemente, a produção de veículos elétricos a bateria está aumentando rapidamente e já quase atingiu o volume de produção dos veículos convencionais.

A MAPAL, como fornecedora de ferramentas de corte para a indústria automotiva, integrou o tópico da sustentabilidade na orientação estratégica da empresa desde o início. A empresa transferiu a sua experiência na usinagem convencional de componentes da transmissão para as peças que estão sendo usinados em veículos movidos a eletricidade. Só por meio de soluções de ferramentas eficientes para processos produtivos em série é que a mudança pode ser moldada com sucesso e de forma sustentável. A MAPAL desempenha um papel importante na resposta aos desafios da mobilidade elétrica e na contribuição para a mobilidade ecológica do futuro.

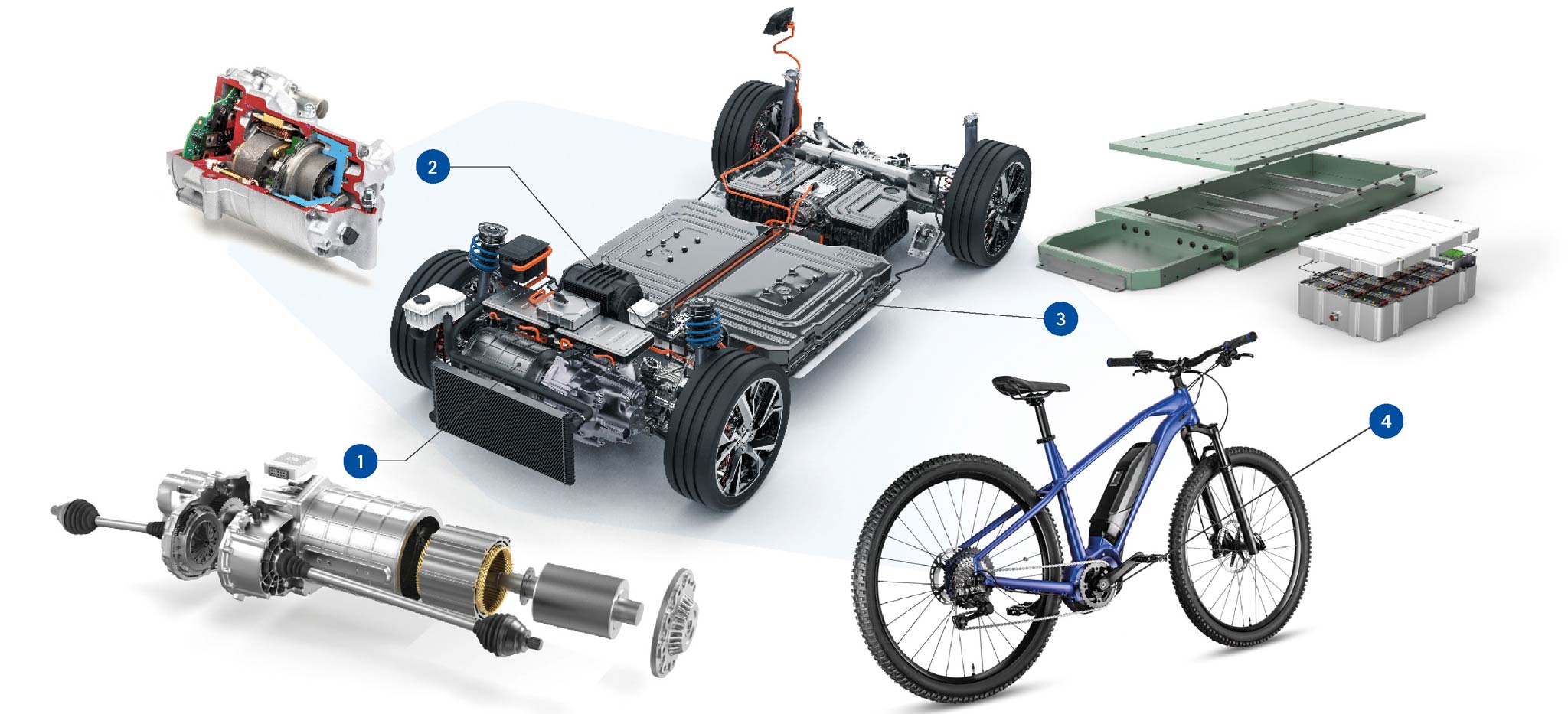

Componentes electrificados

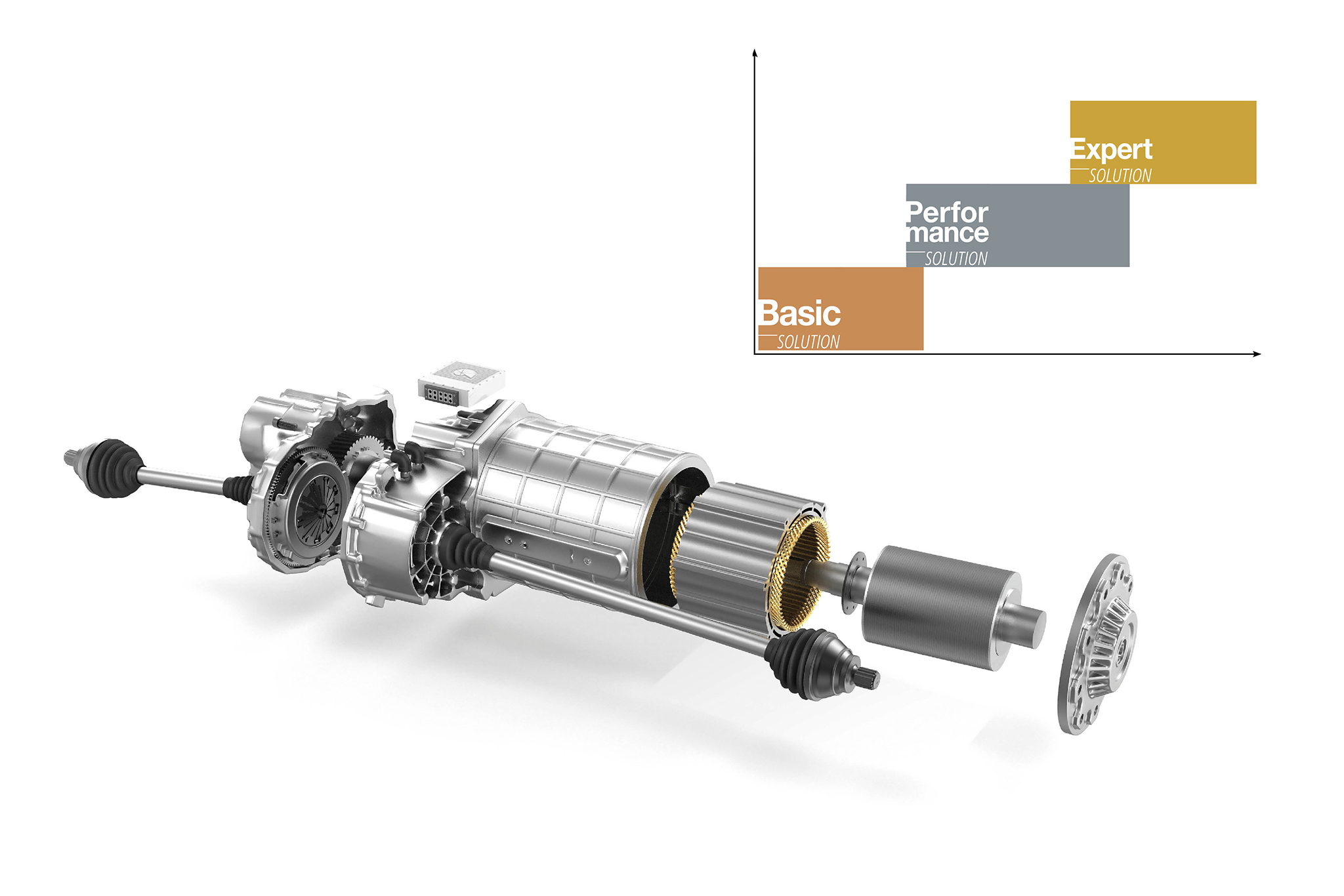

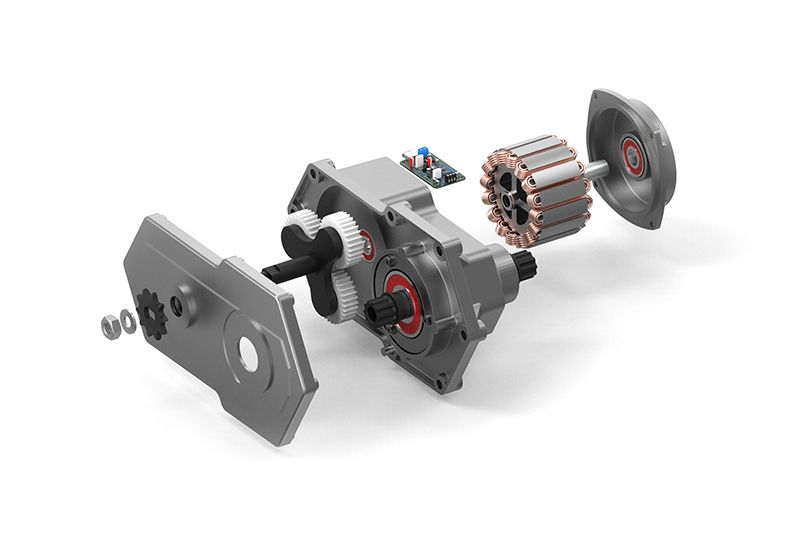

- (1) Propulsores eléctricos

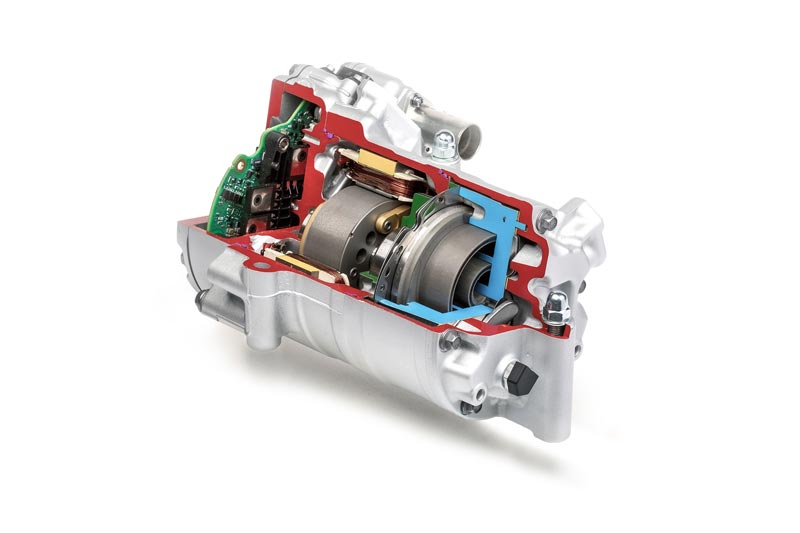

- (2) Electrified auxiliary units

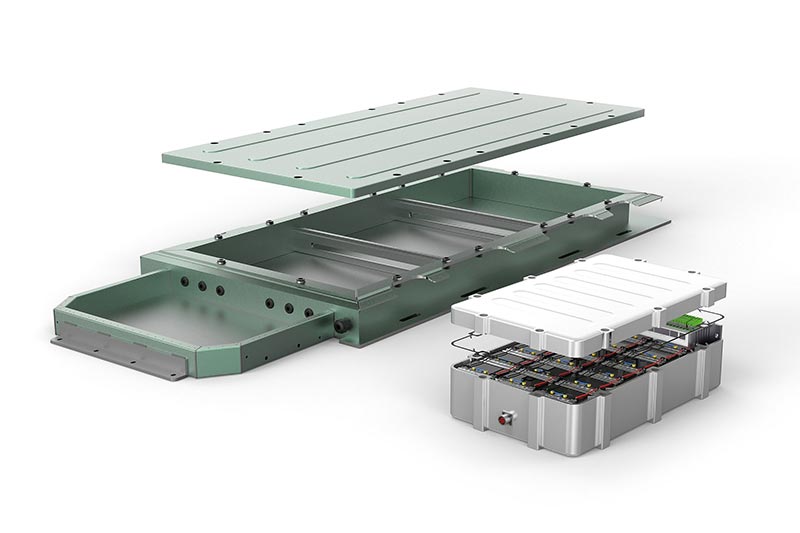

- (3) Energy supply

- (4) Electrified micromobility

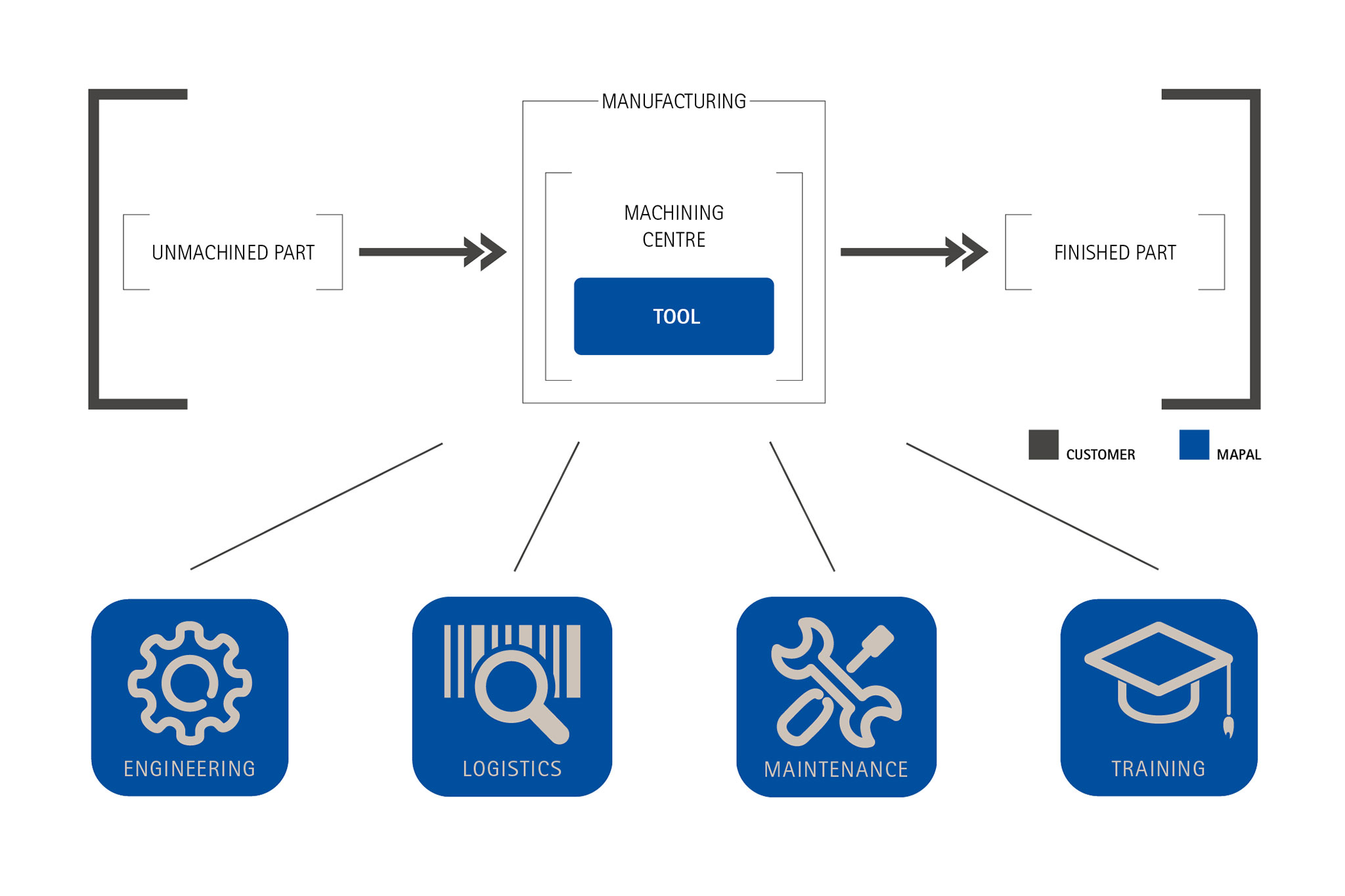

Your technology partner

With the engineering service module, MAPAL guarantees fast, precise and safe manufacturing. Further savings potential can be tapped in the area of logistics and maintenance. And in the area of training, MAPAL ensures that the specialist know-how it has gathered is transparently and completely available to the customer – this gives customers a decisive lead over their competitors.

All of the services offered by MAPAL focus on optimal processes and comprehensive support on the way to Industry 4.0. The goal is to always significantly assist the customer in achieving smooth, productive and economical manufacturing.

Advantages:

- Solutions for complete workpieces including tools, devices, NC programs and commissioning

- Complete process design and implementation from a single source

- Fast and flexible on-site support worldwide

- Efficient and cost-optimised tool technology

- Optimum coordination of tool, workpiece, equipment and machine

- Highest product quality, process reliability and cost-effectiveness right from the start

- Fast throughput from planning to implementation with maximum planning security

Latest News

-

24.09.2025

IMPULSE 85 has been published

Innovations and solutions of the year 2026 are in the focus of issue 85 of the technology magazine IMPULSE

-

12.08.2025

Matthias Winter on key focus areas in the automotive segment

The technological transformation driven by electrification and autonomous driving is placing new demands on the automotive segment. Matthias Winter discusses the key focus areas.

-

29.07.2025

NILES-SIMMONS and MAPAL are setting standards in stator housings

The process developed by NILES-SIMMONS and MAPAL for the complete machining of stator housings for electric vehicle motors is ready for series production.