Large series with solid and adjustable tools

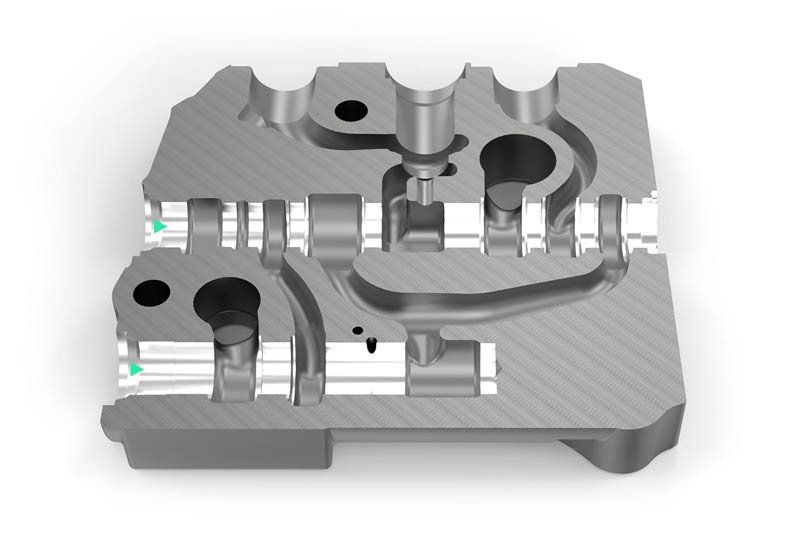

Valve housing EN-GJS-400-15 – spool bore and compensator bore

Initial situation at the customer

- Large-scale series

- Tool setting desired

- High machine hourly rates

- High costs for subsequent single pass honing

Special features of this solution

- Ideally matched separate tools guarantee optimum preconditions for a reduced honing process

- The honing process can be eliminated with certain part requirements

Spool bore

1. Boring

- Optimum results in the pre-machining due to a coordinated piloting and boring process

- Optimum chip flow and extended regrinding options through multicut technology and perfect coolant supply

- No ring formation in the cavities due to special bore geometry → no costs for removal of rings

2. Control edge machining

- Solid carbide profile tool

- Highest accuracy and surface finish of control edges

- Defined control edges without macroscopic flaws

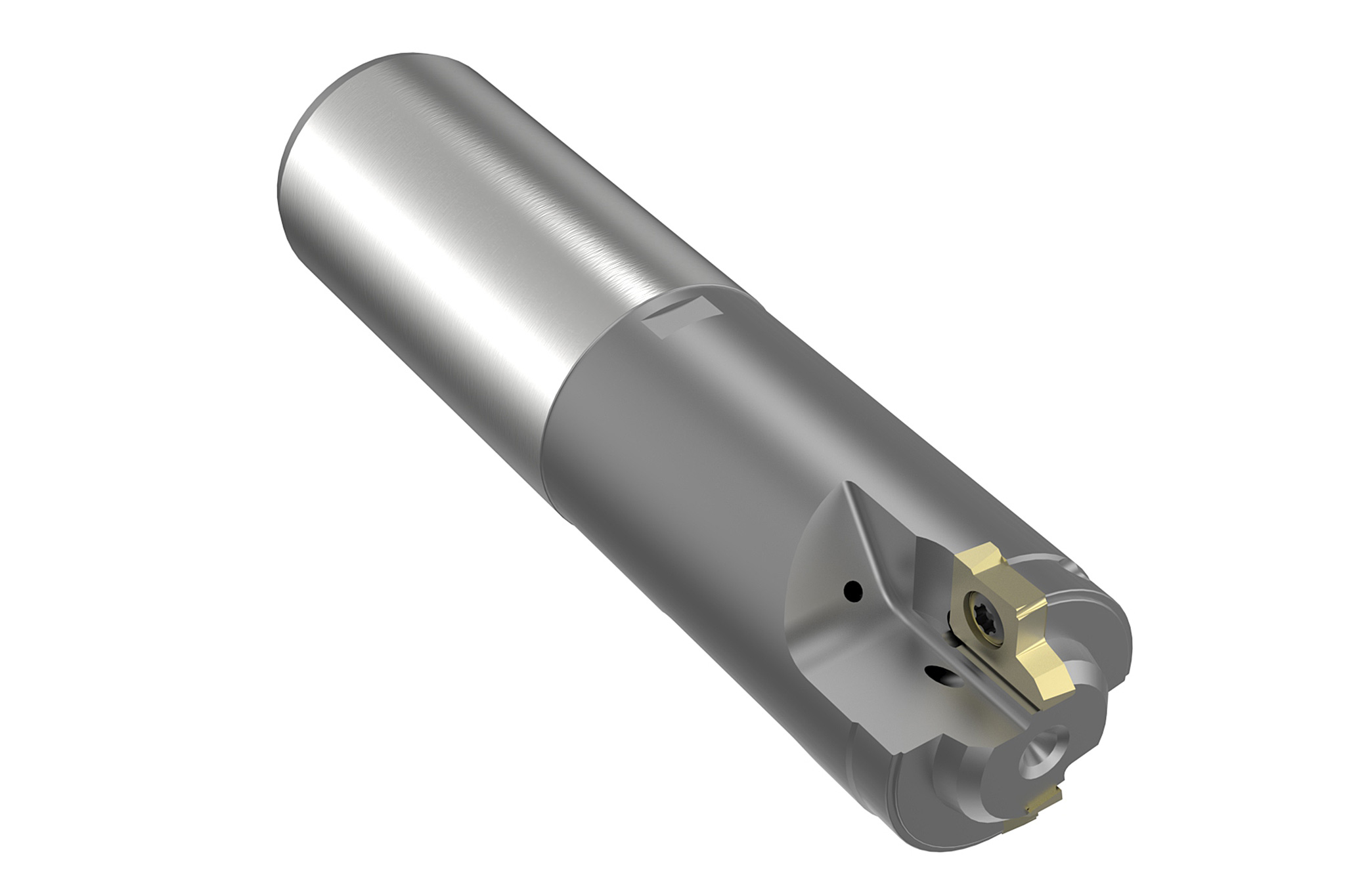

3. Fine boring

- Fine boring tool with EasyAdjust system and guide pads

- Reliable precision machining with easy handling

- Best cylindrical forms due to optimum guidance

Compensator bore

1. Boring

- Solid carbide boring tool with six margin lands and special lead geometry

- Straight bore, ideal chip flow und guide across the entire bore length

- Reduced non-productive times due to two machining operations in one tool

2. Contour machining

- Double edge boring tool with form cutting edges

- Reliable machining of the contour

- Easy handling with low cutting material costs

3. Fine boring

- Fine boring tool with EasyAdjust system and guide pads

- Reliable precision machining with easy handling without subsequent honing

- Best cylindrical forms due to optimum guidance

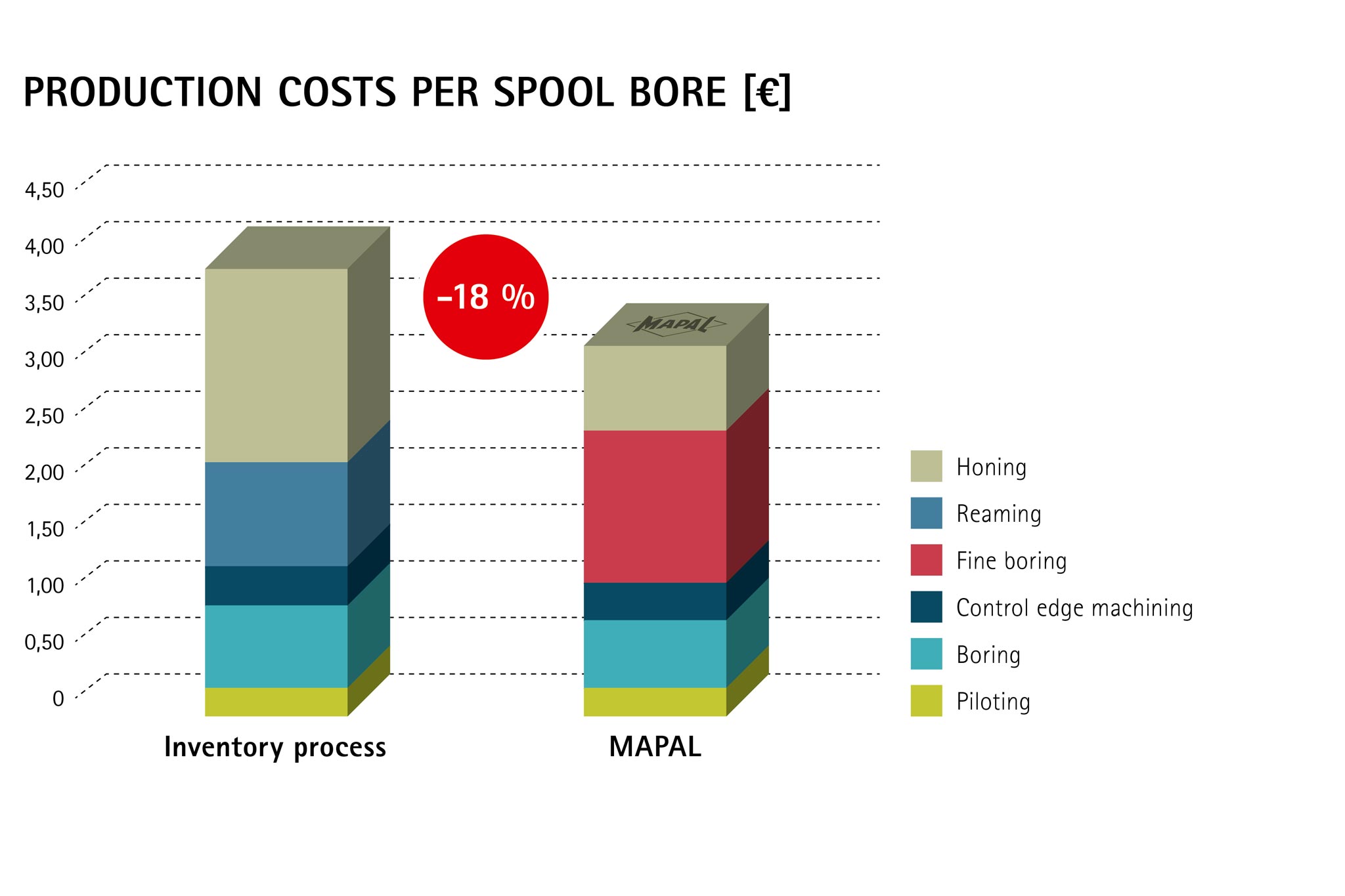

Advantages

- Expensive honing process shortened in spool bore

- Low tool costs per bore

- Shorter non-productive times due to clever engineering in cooperation with the customer

- Significant cost savings, as honing process no longer required in the compensator bore

![ANNUAL PRODUCTION COSTS OF THE COMPENSATOR BORE [€]](/medias/sys_master/root/h6c/h6e/9043460718622/Grafiken_EN-13/Grafiken-EN-13.jpg)