TOOLTRONIC and facing heads

Depending on the application, the MAPAL specialists can choose from various tool concepts from the actuating product range:

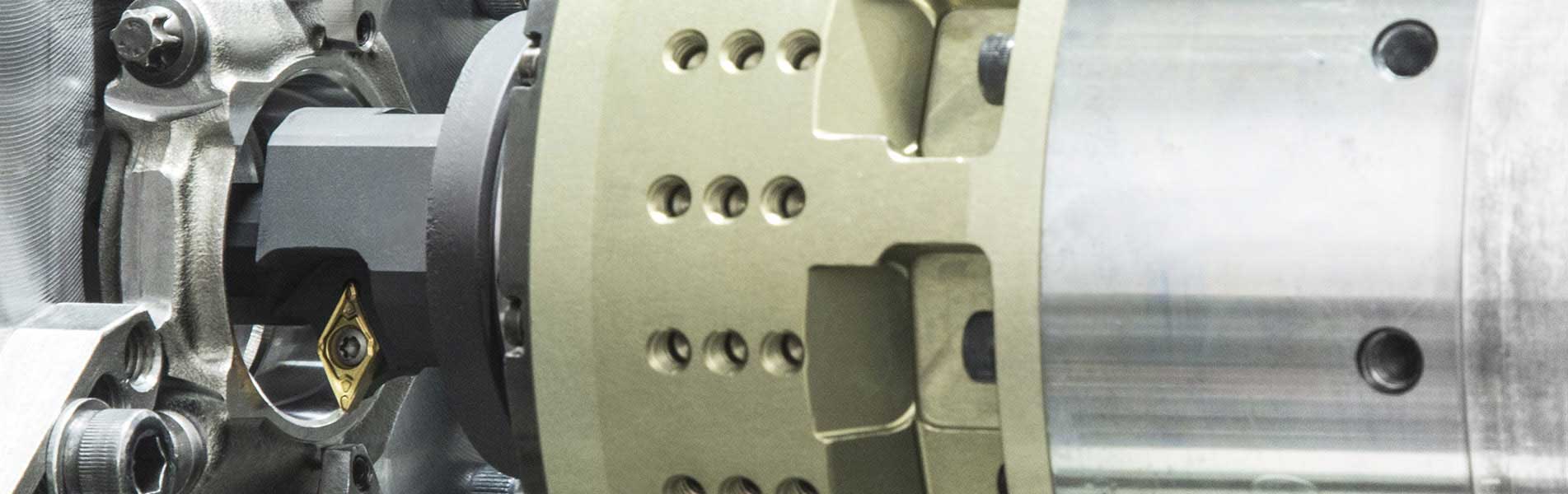

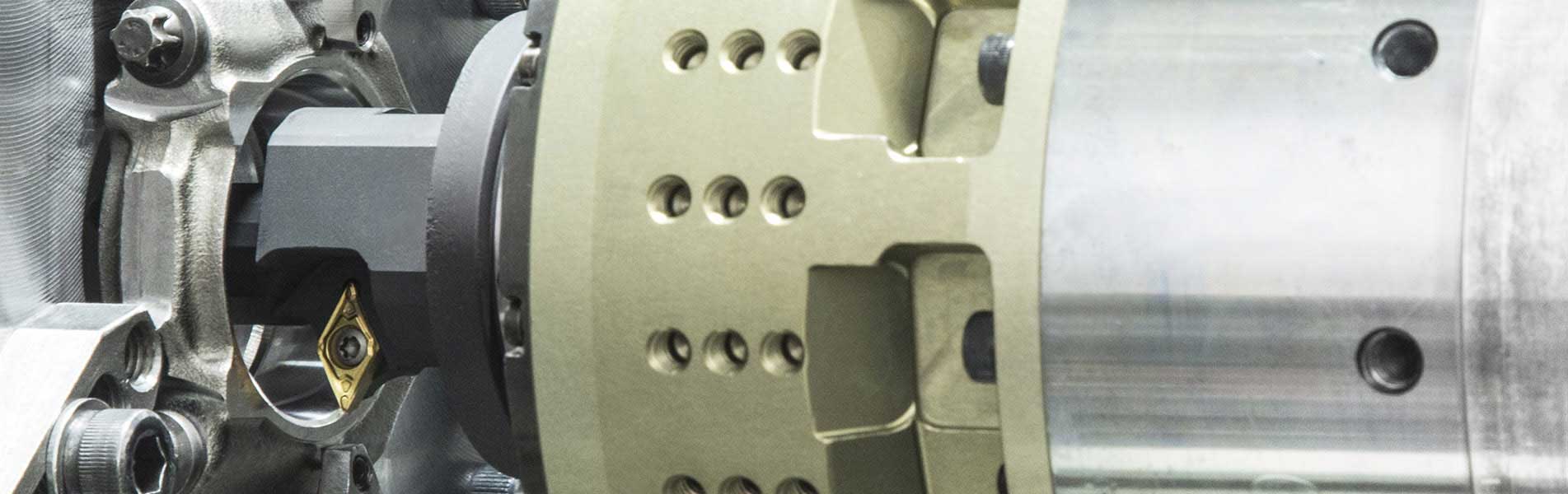

The mechatronic tool system TOOLTRONIC is available as the universal input for more manufacturing versatility and flexibility on machining centres and special machines. TOOLTRONIC for machining centres is a full interchangeable tool axis that permits a broad spectrum of applications.

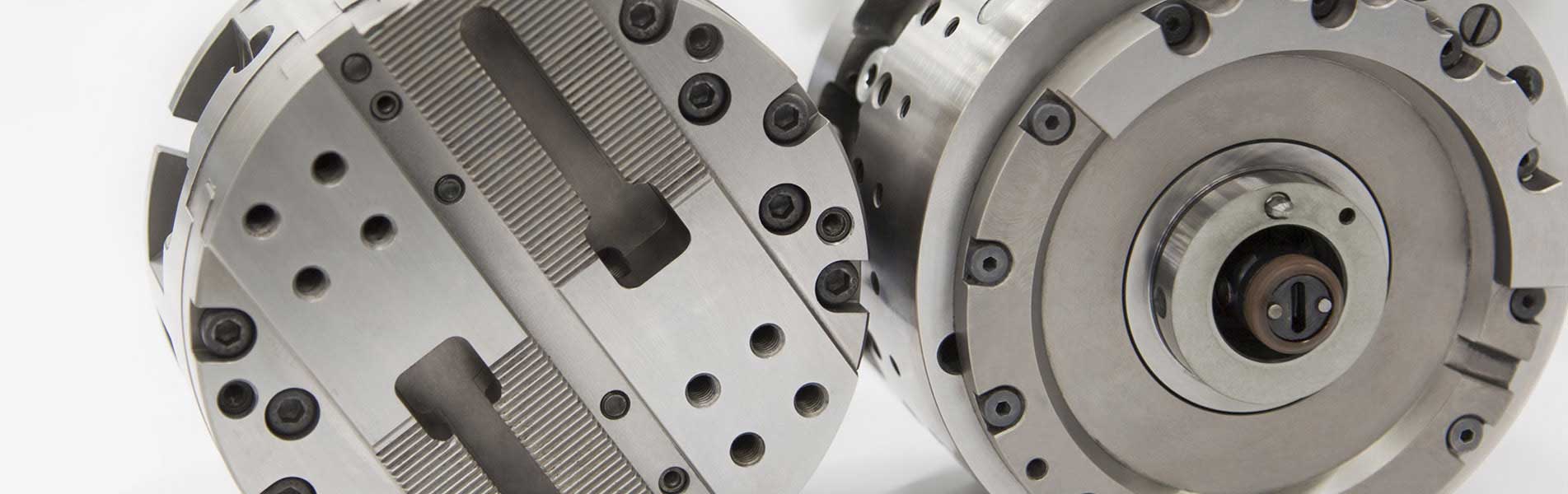

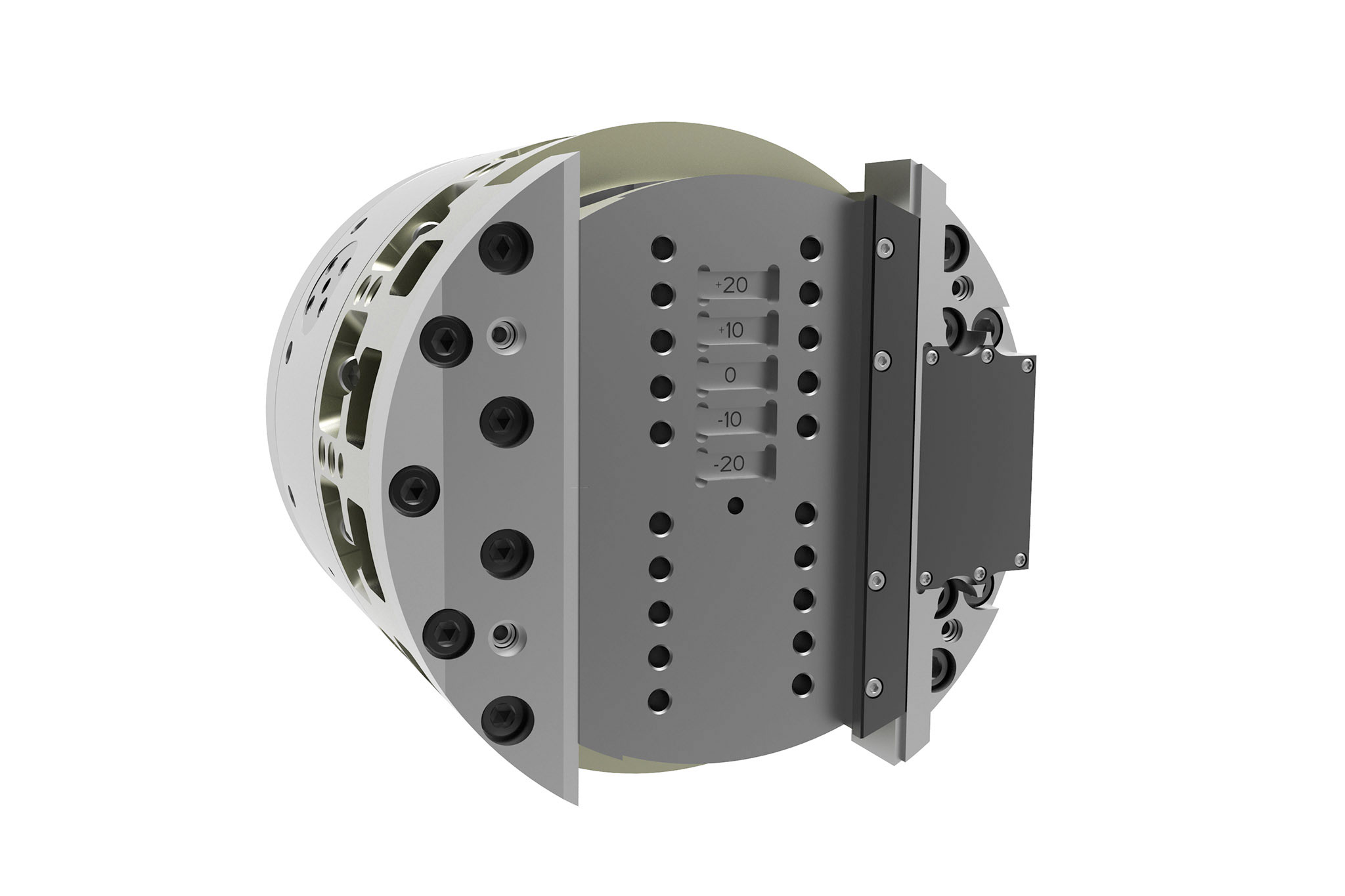

Facing heads are used for face turning, recessing and machining contours predominantly in large-scale series production on special machines. The operation of this slide tool and the actuation of the tool holder and inserts is via an NC-controlled crossfeed device that is on the spindle drive or on the rear of the feed unit.

The mechatronic tool system TOOLTRONIC is available as the universal input for more manufacturing versatility and flexibility on machining centres and special machines. TOOLTRONIC for machining centres is a full interchangeable tool axis that permits a broad spectrum of applications.

Facing heads are used for face turning, recessing and machining contours predominantly in large-scale series production on special machines. The operation of this slide tool and the actuation of the tool holder and inserts is via an NC-controlled crossfeed device that is on the spindle drive or on the rear of the feed unit.

The mechatronic tool system TOOLTRONIC

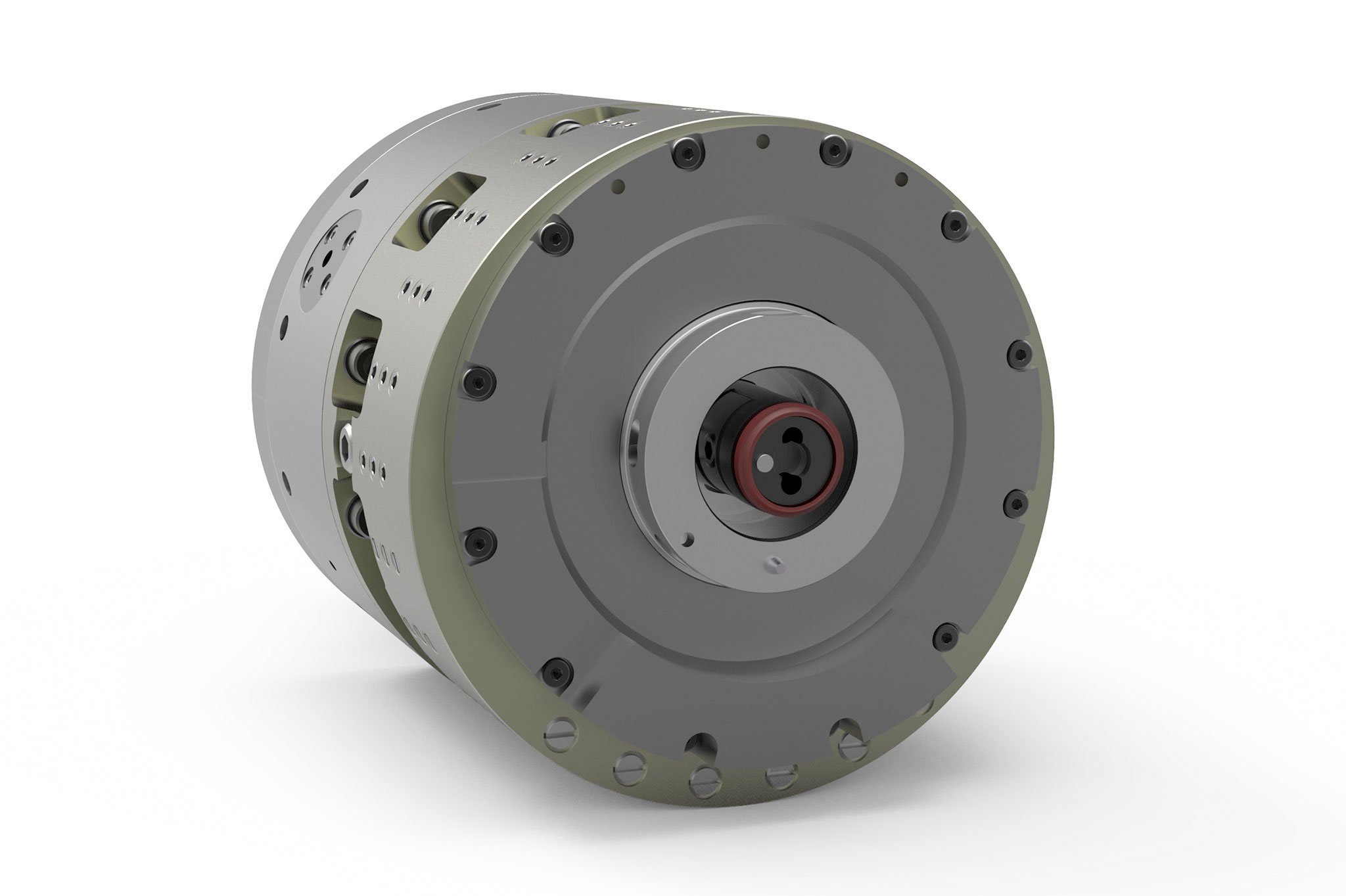

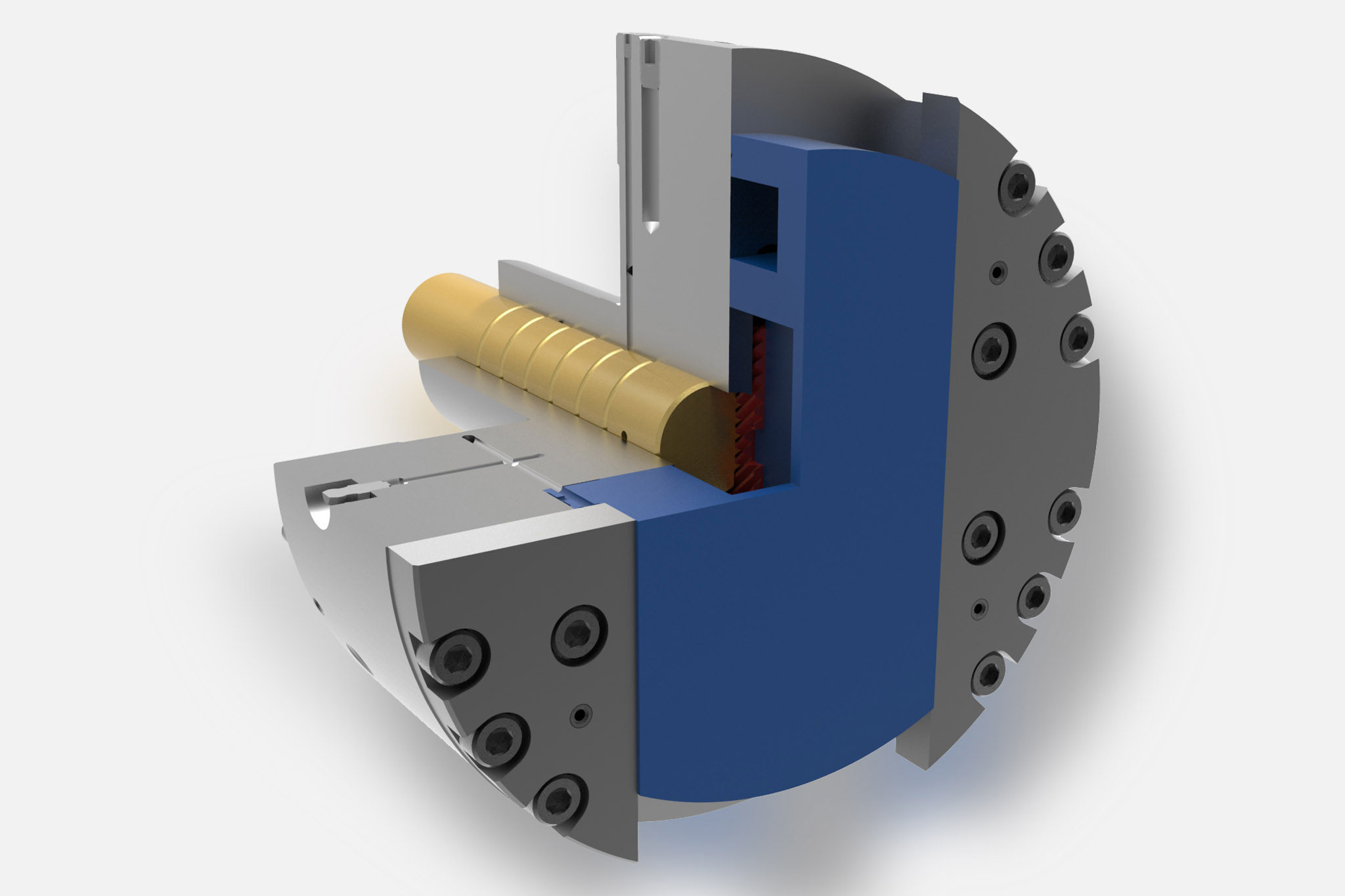

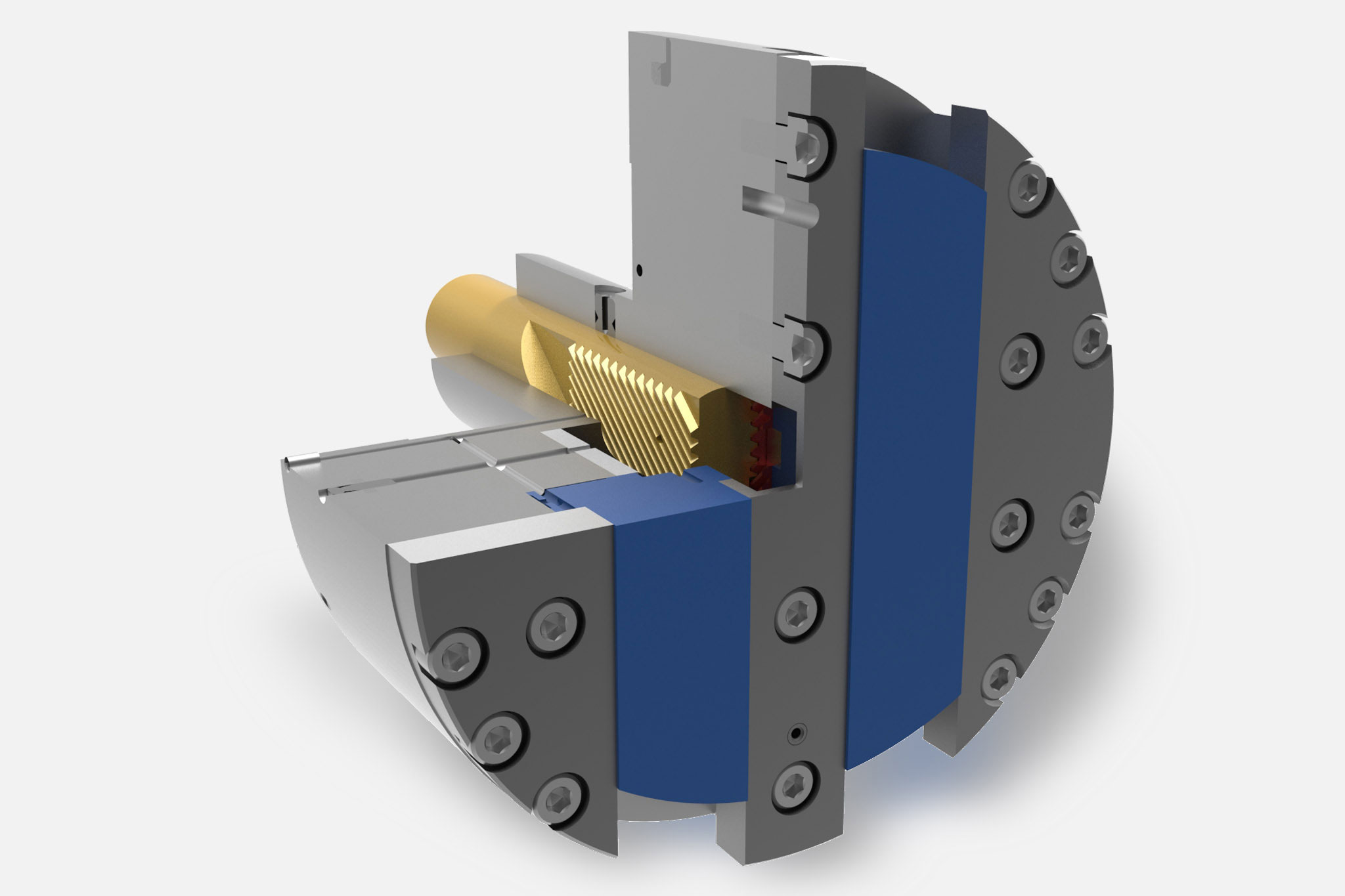

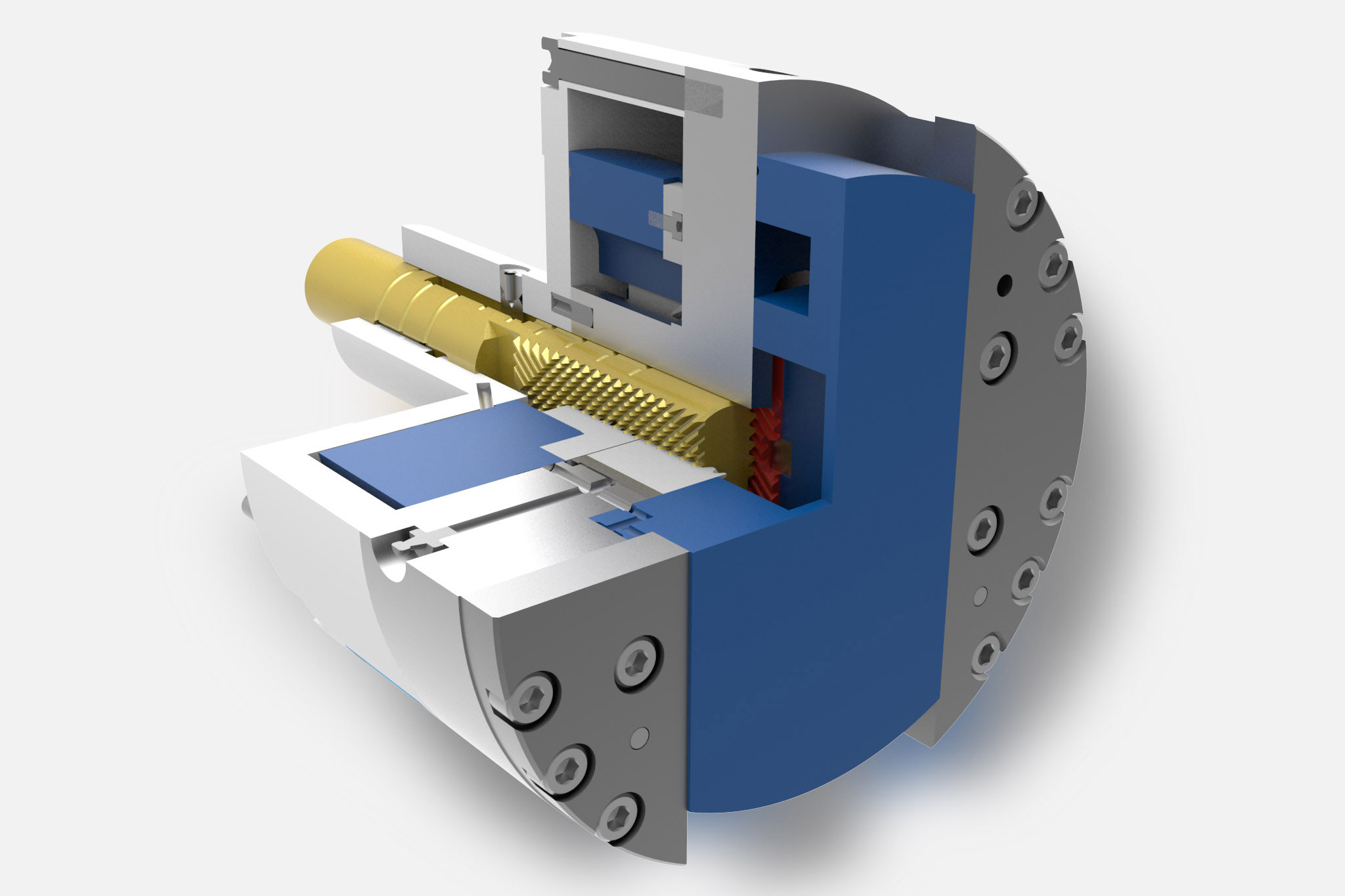

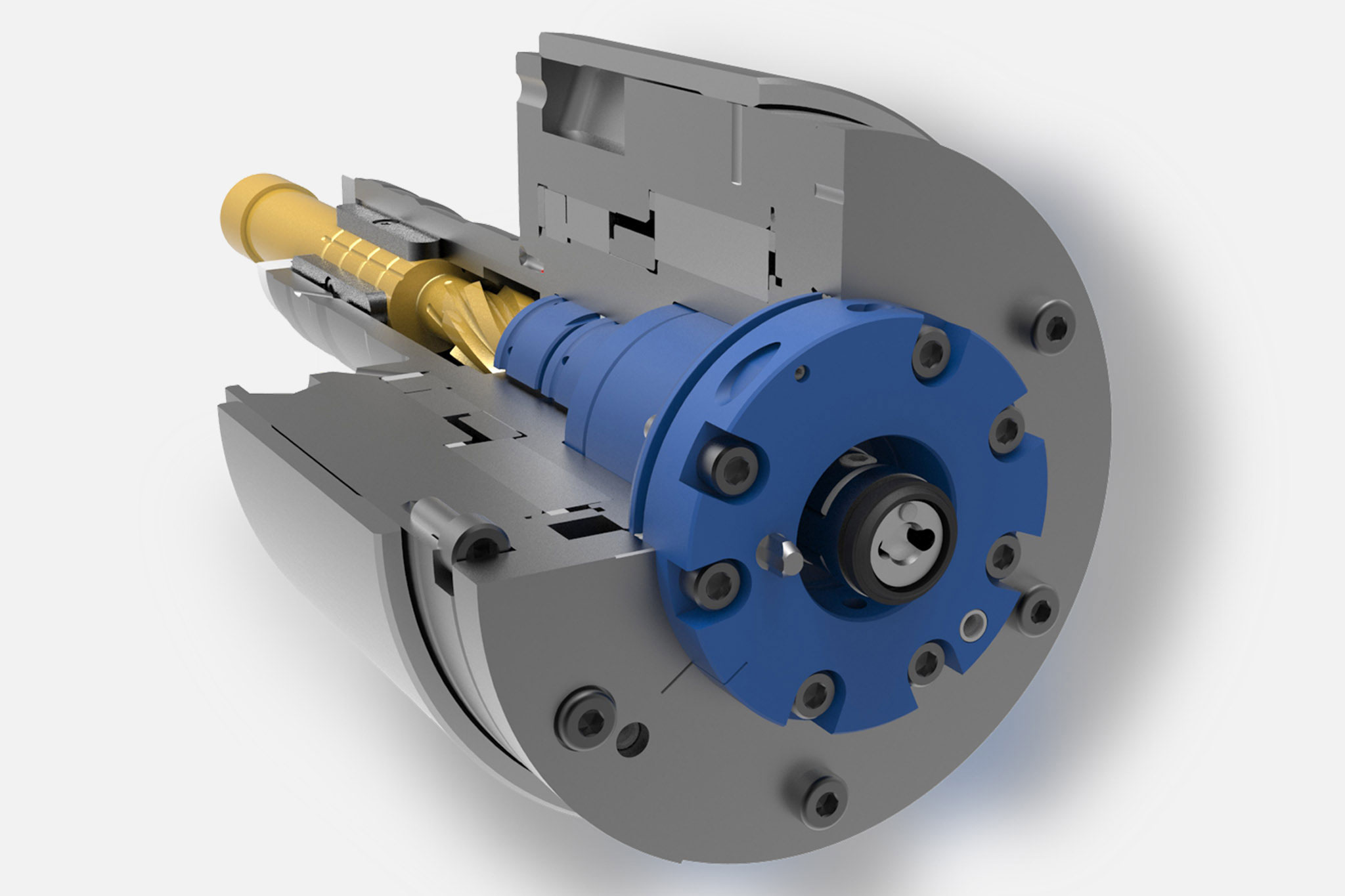

The TOOLTRONIC mechatronic tool system implements actuation movements easily and reliably on both machining centers and special machines. The processing of contours, undercuts and non-cylindrical bores is just as possible as closed control loops for cutting edge compensation or the simple production of multi-variant part families.

With its inductive energy and bidirectional data transfer, the self-contained drive module represents a full-fledged NC axis integrated into the higher-level machine control. This means that the full functionality of modern CNC controls can also be used in conjunction with TOOLTRONIC.

Depending on the machining task, different facing heads (outputs) from MAPAL are used on the modular TOOLTRONIC connection. As standard, eccentric actuating tools (EAT) are used. Applications that require a large stroke with a tailored spindle speed are covered using linear actuating tools (LAT).

With its inductive energy and bidirectional data transfer, the self-contained drive module represents a full-fledged NC axis integrated into the higher-level machine control. This means that the full functionality of modern CNC controls can also be used in conjunction with TOOLTRONIC.

Depending on the machining task, different facing heads (outputs) from MAPAL are used on the modular TOOLTRONIC connection. As standard, eccentric actuating tools (EAT) are used. Applications that require a large stroke with a tailored spindle speed are covered using linear actuating tools (LAT).

Facing heads

Facing heads are used for face turning, recessing and machining contours predominantly in large-scale series production on special machines.

The operation of this slide tool and the actuation of the tool holder and inserts is via an NC-controlled crossfeed device that is on the spindle drive or on the rear of the feed unit.

The MAPAL standard range of facing heads consists of the following four concepts:

The operation of this slide tool and the actuation of the tool holder and inserts is via an NC-controlled crossfeed device that is on the spindle drive or on the rear of the feed unit.

The MAPAL standard range of facing heads consists of the following four concepts: