19.01.2022

When nothing is allowed to go wrong

MAPAL offers process reliability for drilling, reaming and threading operations

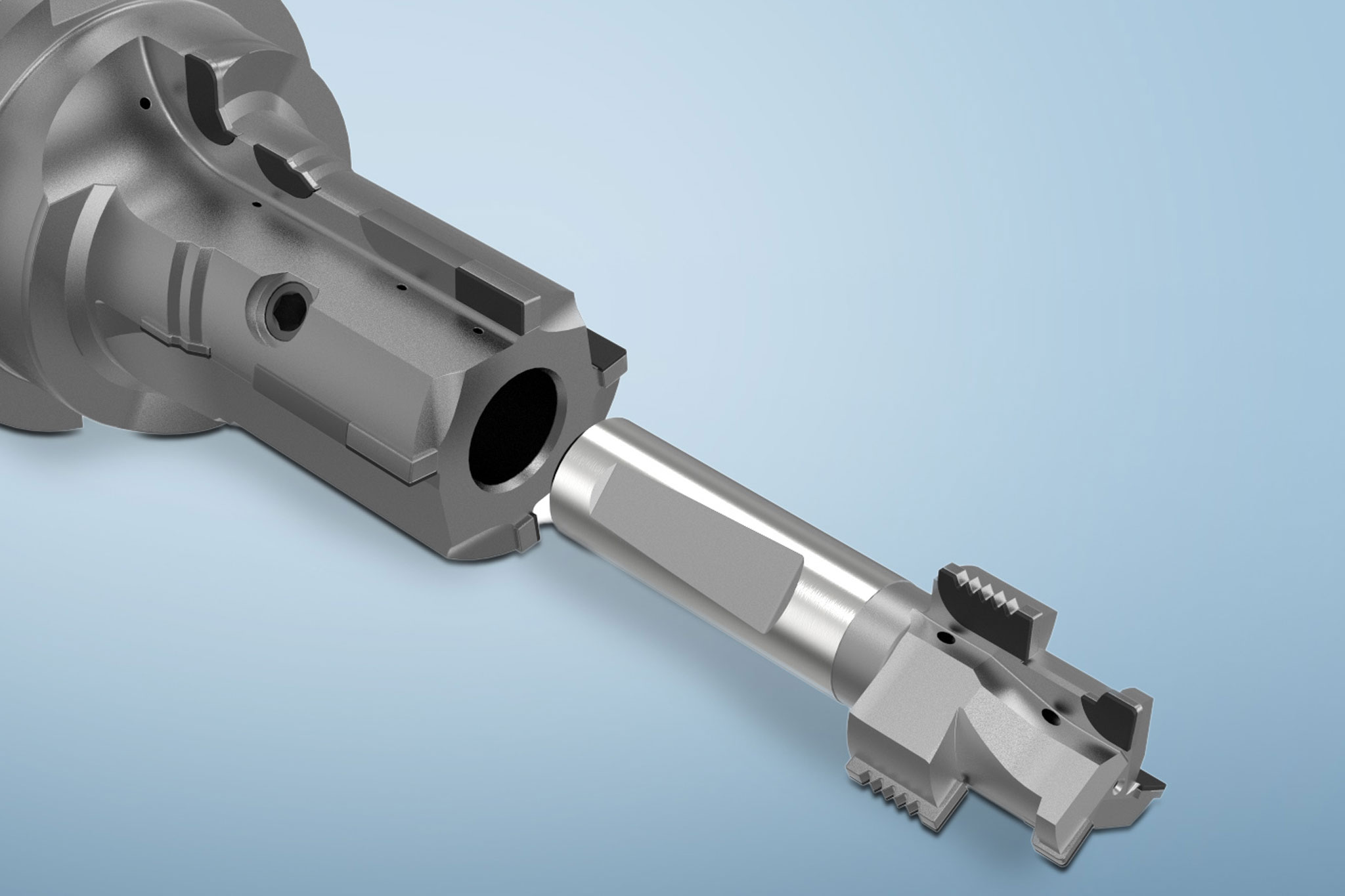

A lot has already happened in the production process before methods like drilling, reaming or threading are used. This makes it all the more important that tool failure doesn‘t lead to damage or even destruction of the almost finished part during these final machining steps. MAPAL‘s tools are more than just extremely reliable – they also enable high productivity. Three-edged drilling and reaming in one step are just as much a part of this as the thread milling cutter integrated into a combination tool.

Three guiding chamfers for more speed

Drilling and reaming in one tool

Tangled chips, which are drawn into the secondary flute, wrap around the tool and destroy the part, are an absolute nightmare for the user. With its three-flute solution, MAPAL has been able to eliminate this problem and ensures high process reliability even with long-chipping steel materials. For the combination tool, the drill with three cutting edges was supplemented by three further guiding chamfers. Together with these six guiding chamfers, the self-centring chisel edge ensures that the drill reamer is very insensitive to different application parameters and always offers the highest process capability. The tip looks like a small star and has a screw face grinding with a chisel edge. It guarantees the highest positioning accuracy of the tool.

With the help of its test series, MAPAL‘s Research and Development proves that changes in the cutting values cause hardly any deviations in the bore diameters. This saves time-consuming searches for the right cutting parameters during manufacturing, which reduces the setup effort and leads to faster results. The roundness also remained constant over hundreds of test bores.

MAPAL offers the Tritan-Drill-Reamer for diameters from 4 to 20 mm in lengths of 3xD and 5xD with internal cooling. Diameters in 1/100 intervals are also available for producing a wide range of fits with the drill reamer with high precision as well as achieving further IT7 tolerances.

PCD thread milling cutter piggybacking along

There is no need to use the additional tool component for the same work step. For example, a custom tool can be designed primarily for boring and applying a chamfer, and the thread is created at a completely different location on the part. With one tool change eliminated, the cycle time is shortened. „We always spring into action when a very large number of threads need to be produced cost-effectively or high precision is required, “ says Matthias Fuchs, Product Specialist for PCD tools at MAPAL.

The change from a solid carbide cutting edge to polycrystalline diamond as the cutting material can bring different advantages. The PCD thread milling cutter has a significantly longer tool life, enables longer dimensional accuracy of tolerances, such as the flank angle, with higher cutting values, and maintains the required surface qualities. MAPAL demonstrates how this works in practice with a large number of hands-on examples. Compared to a solid carbide tool, the cutting values for thread milling in a cylinder head could be increased by 30 percent. In the manufacturing of brass flow metres, the cycle time was reduced by 40 percent compared to solid carbide. A PCD thread milling cutter finishes M12x1 fine threads in highly hardened and tempered forged aluminium for a common rail flange with a tool life of around 85,000 threads.

In automated assembly lines, a burr-free and bevelled thread increases process reliability during assembly. There is also the option of integrating a deburring cutter, which saves the extra machining step of deburring.

Another advantage is that users have to reset the tool much less frequently. With solid carbide tools, the shape of the threads produced changes with increasing wear and tear, which requires corrections in the machine control. In the production of an M12 thread for a customer, the tool life advantage of the PCD thread milling cutter is clearly demonstrated: while it reaches a life of 120,000 parts, its solid carbide counterpart reaches only 14,000 in comparison. To achieve these quantities, the solid carbide thread milling cutter required four radius corrections of 50 µm each, while the PCD thread milling cutter only needed one adjustment of 5 µm.

As an alternative technology, the tap drill produces the thread in a single step, while the thread milling cutter first requires a core bore. Nonetheless, when threading in large-scale manufacturing, milling is preferred for reasons of process reliability, to prevent problems with tool breakage or chip removal. In the end, you have to make sure nothing else goes wrong.

Contact

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Phone: +49 7361 585 3342