Luft- und Raumfahrt

Hochfeste und gleichzeitig leichte Materialien sind in der Luftfahrt von zentraler Bedeutung. Durch neuartige Materialkombinationen lässt sich das Gewicht weiter senken, die Festigkeit und Korrosionsbeständigkeit erhöhen sowie eine Vereinfachung der Montage durch integrative Bauweise erreichen. Während Strukturbauteile aus Aluminium, Titan oder hochfesten Stählen auf Bearbeitungszentren oder Portalmaschinen bearbeitet werden, erfolgt die Bearbeitung in der Endmontage durch handgeführte Maschinen, Bohrvorschubeinheiten oder Roboter.

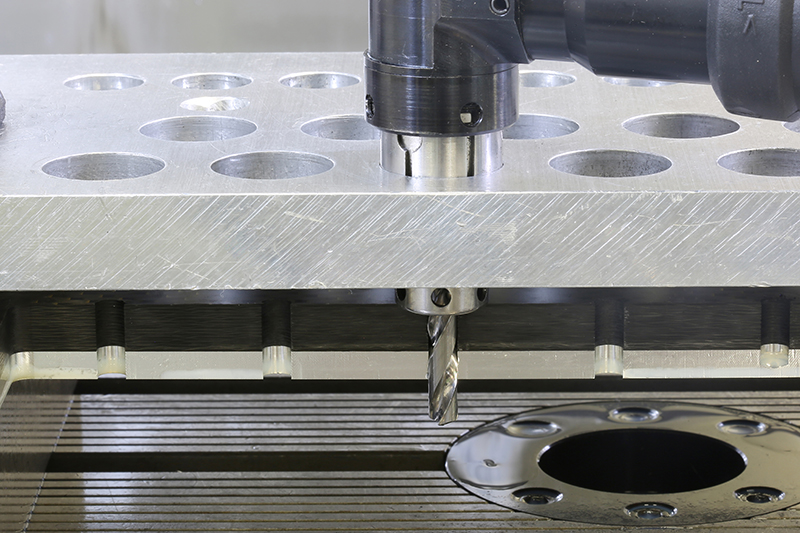

Teilefertigung

Bei der Teilefertigung erfolgt die Bearbeitung der Bauteile stationär, d.h. Bauteile werden in einer Maschine in einer oder mehrerer Aufspannungen zerspant. Während kleinere bis mittlere kubische Bauteile auf einem Bearbeitungszentrum (BAZ) bearbeitet werden können, erfordern große Bauteile spezielle Portalmaschinen.

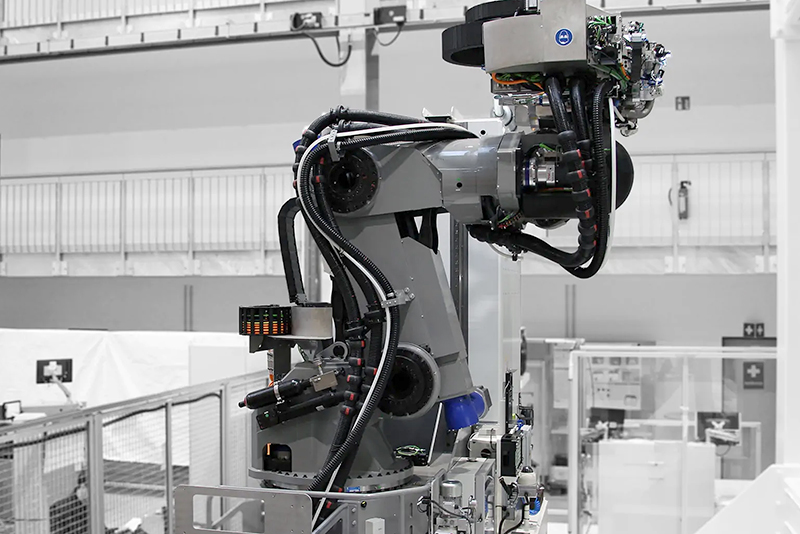

Endmontage

Bei der Endmontage eines Flugzeugs wird aufgrund der Größe des Objekts auch heute noch mit handgeführten Maschinen gearbeitet. In sogenannten Final Assembly Lines (FAL) werden zum Beispiel Nietlöcher in die Außenhaut des Flugzeugrumpfs eingebracht. Die Werkzeuge sind mit speziellen Führungselementen ausgeführt.

Latest news in the aerospace sector

-

24.10.2025

Portrait: MAPAL Centre of Competence PCD tools

With the Centre of Competence for PCD tools, MAPAL sets standards in customer service, technology, efficiency and sustainability.

-

15.10.2025

Successful tooling solutions from MAPAL increase productivity for customers.

Increasing customer productivity is at the heart of MAPAL’s standard processes for the industrial manufacturing of strategic components.

-

06.10.2025

Innovations and solutions of MAPAL

MAPAL presents its 2026 innovations and solutions in a comprehensive brochure.