Bearing cover

Bearing cover EN-GJS-400-15

Initial situation at the customer

- Process optimisation required due to increasing lot numbers in mass production

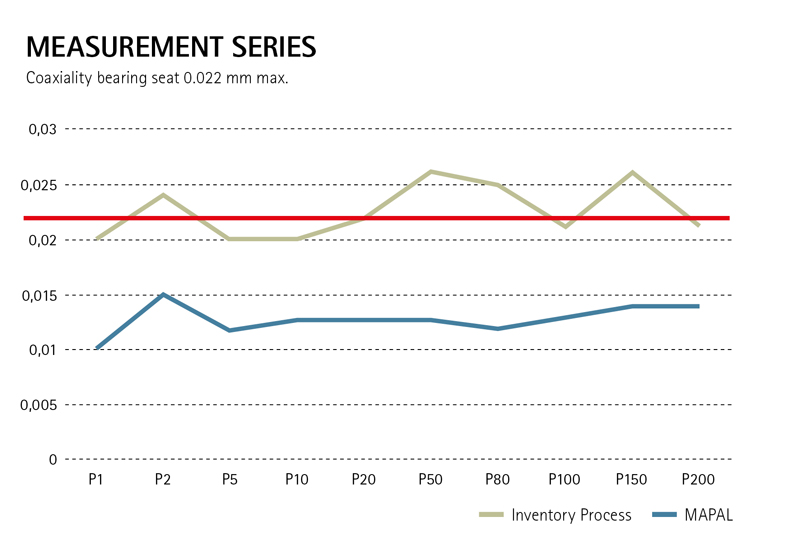

- Quality issues due to fluctuations in form and positioning of bearing seats

Special features of this solution

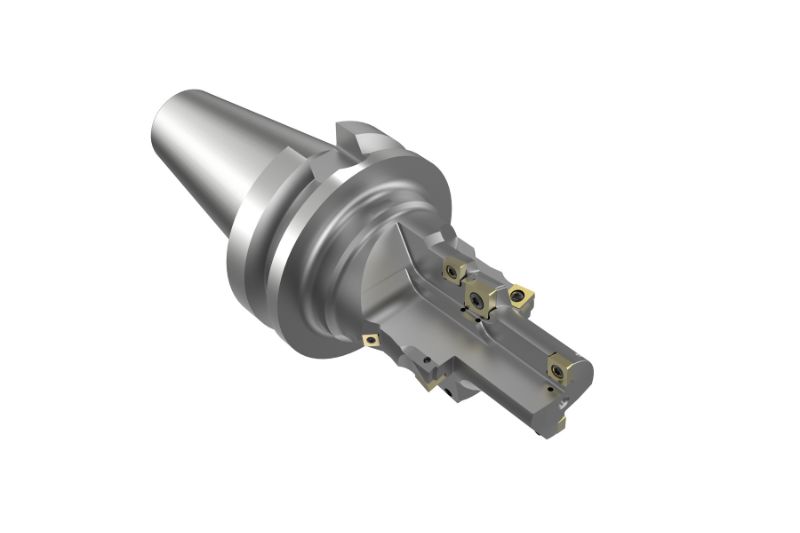

- Multi-stepped fine boring tool guarantees optimal concentricity of the bearing bores in mass production

- Soft-cutting tangential indexable insert requires less spindle power

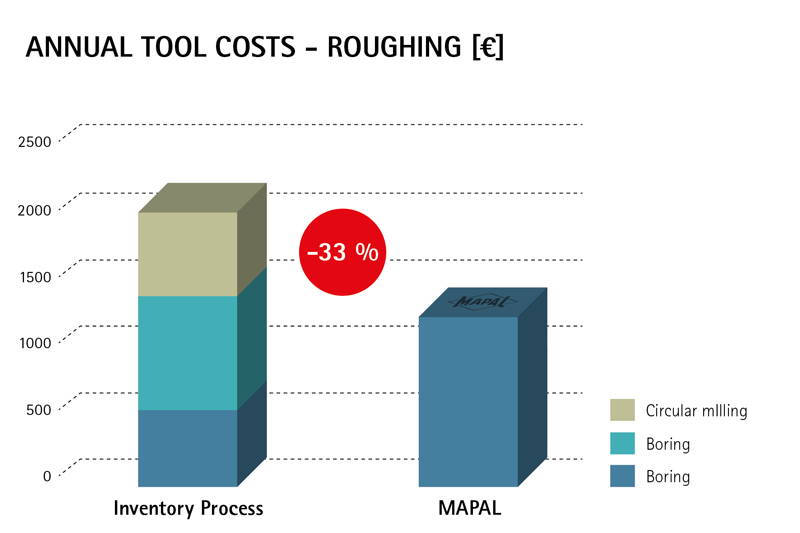

- Multi-stage combination solution offers high degree of economic efficiency and reduced tool costs

- Low cutting material costs thanks to a solution with indexable inserts

Bearing seat

Advantages

- Considerable cost reduction due to stable quality

- Ideal shape and position tolerance increases parts quality

- The tool concept can handle growing lot sizes efficiently in series production