パイロット穴加工

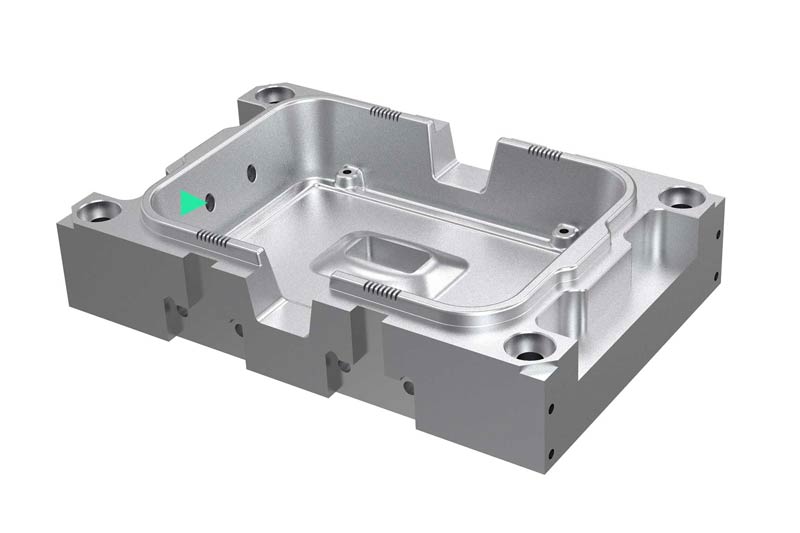

冷却システムのための深穴は、主にプラスチック射出成形の分野で非常によく使われます。特に長いドリルツールを適切にガイドするには、短いツールで穴をパイロット加工することをお勧めします。マパールはここで適切な製品を供給するだけでなく、真円度や精度の面で目標を確実に達成するために、専門的なサポートも行っています。

また、穴あけ加工は傾斜面で行われることが多いため、ツールの曲がりや破損を防ぐために、穴をパイロット加工する必要があります。

また、穴あけ加工は傾斜面で行われることが多いため、ツールの曲がりや破損を防ぐために、穴をパイロット加工する必要があります。

ソリッドドリリング

穴径や特徴が多様であるため、ツールおよび金型製作にはさまざまなソリッドドリルが用意されています。タップドリル、エジェクターピンのガイド穴、ピンの部分穴などは、ほんの数例です。

深穴ボーリング

ツールや金型製作では、最大40xDや50xDの深穴が非常に一般的です。この用途には、特別なツールが必要です。ガンドリルが最も一般的で、専用のボーリング機で使用します。穴径12mmまでの小・中型部品には、ソリッドカーバイドドリルが本当の意味での選択肢となります。深穴ドリルは、2つのガイディングチャンファを備えているため、穴内での良好なガイドが保証されます。

リーミング

特定のピンや位置へのボーリングは、真円度や直径など高い精度が要求されます。そのため、最終的なリーミング作業が必須となります。これらの穴の前処理は、望ましい結果を得るためにリーミングツールの要求を満たす必要があります。

マパールの数十年にわたる専門知識により、特定の要件に合わせて特別に選択された幅広い製品が市場に提供されています。

面取り加工

各穴は通常、エッジのテーパーシンカーで前処理されます。面取り加工は簡単なアプリケーションですが、穴の中には特殊な表面品質が要求されるものがあります。一般的なツールはソリッドカーバイド製ですが、ハイス製もあります。マパールの革新的なテーパーシンカーは、優れた性能と高い表面品質により、皿取り加工にも有利です。