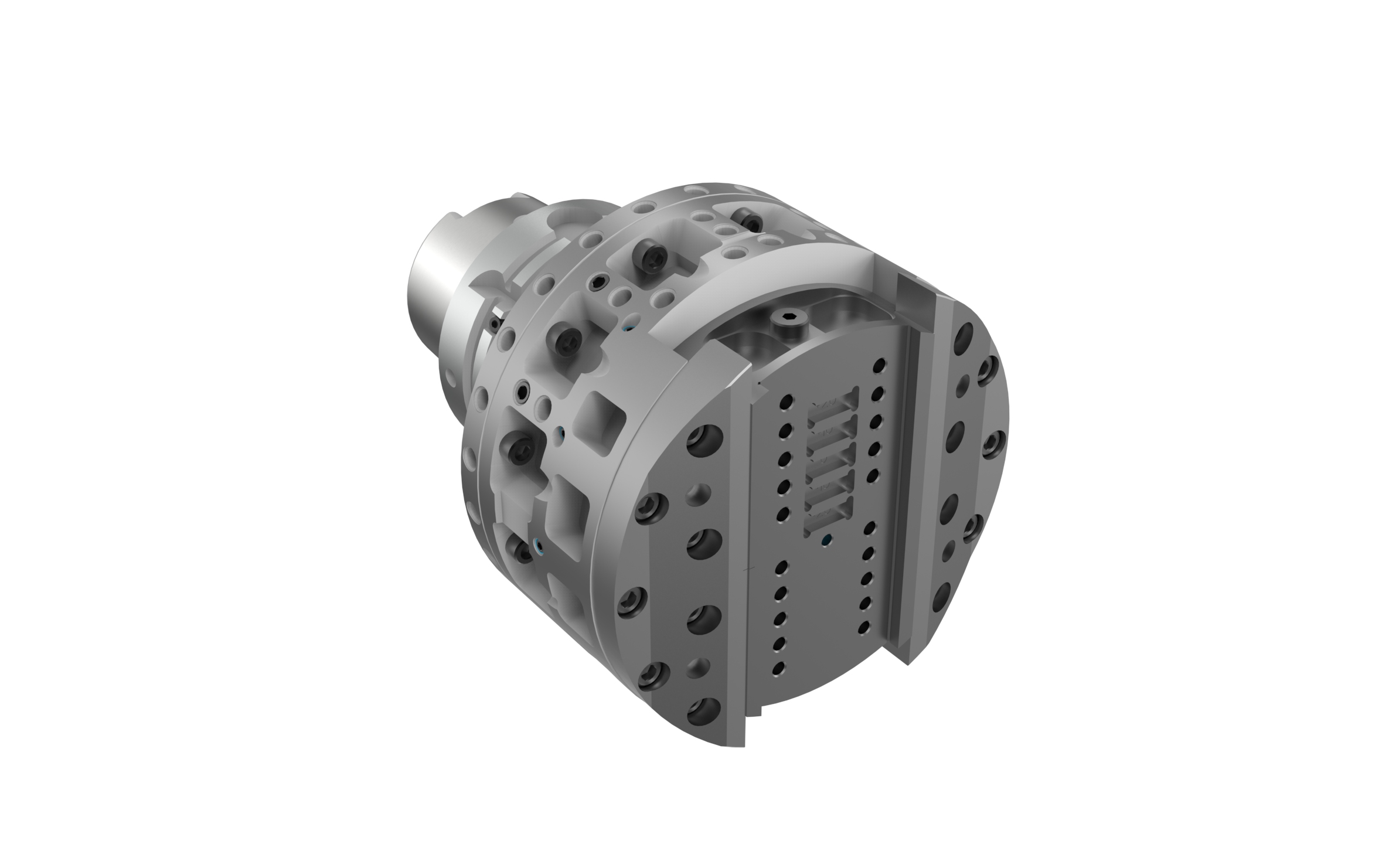

アクチュエータハウジング

制御技術による加工ソリューション

アクチュエーターハウジング(AlSi10)

お客様の初期の加工状況

- 単一の工具システムでの複雑な輪郭加工の要求に対応:端面加工、面取り、内径加工、1:50(1.1146°)のテーパ加工

- 高い形状 & 位置精度およびIT8公差への高い要求

Besonderheiten der Lösung

- Innen sowie Außenbearbeitungen können prozesssicher mit optimaler Koaxialität realisiert werden

- Möglichkeit für automatischen Werkzeugwechsel

- Einstellen der Werkzeuge Hauptzeitneutral durch Schwesterwerkzeuge

- Voreinstellen auf Einstellgerät möglich durch flexiblen Prozess

- Möglichkeit zum Einsatz von Standardwerkzeugen (z. B. Bohrer oder Fräser) in der gleichen Spindel

- Wendeschneidplattentechnologie für geringe Schneidstoffkosten

Werkzeughighlights

- HSK-A100 mit U-Achse (Drehachse)

- Innen- und Außenbearbeitung mit einem Aufsatzwerkzeug

- Planhub 56 mm

- Durchmesserbereich für die Bearbeitung 112 mm

- Aufsatzwerkzeug in fünf Stufen versetzbar für maximalen Durchmesserbreich

- Optimale KSS-Versorgung durch innere Kühlmittelzuführung direkt auf die Schneiden

Vorteile

- Komplexe Konturen und geforderte Genauigkeiten durch nur ein Werkzeugsystem realisierbar

- Geringe Schneidstoffkosten im Serienprozess da nur zwei Werkzeugtypen für alle Varianten nötig

- Maximale Prozesssicherheit bei hoher Varianz, da Konturen und Kegelform 1:50 (1,146°) frei programmiert und korrigiert werden können

- Technologiepartnerschaft mit MAPAL ermöglicht das Zusammenfassen aller Bearbeitungsschritte