08.10.2020

Multi-Site Tool Management 4.0

MAPAL takes over tool management at the Hitachi Automotive Systems Group in Poland, Mexico and TurkeyMAPAL takes over tool management at the Hitachi Automotive Systems Group in Poland, Mexico and Turkey

For manufacturing companies, procuring and preparing tools requires a great deal of time and effort that demands both capacity and competence. For that reason, the Hitachi Automotive Systems Group has entrusted tool management for the entire brake manufacturing process at three of its locations – in Mexico, Turkey and Poland – to MAPAL. By doing so, the company benefits not only from tool management but also from the opportunities provided by digital connectivity.

At its three factories in Mexico, Poland and Turkey, Hitachi Automotive Systems Group primarily manufactures disc and drum brakes. “We have been successfully working with the Turkish factory in Bursa for 13 years,” recalls Frank Stäbler, Head of Tool Management Services at MAPAL. Over time, the two companies expanded their collaboration. “Following our work at the Turkish factory, Hitachi Automotive Systems Group entrusted us with the tool management for its facility in Wrocław, Poland,” says Stäbler. Their most recent partnership is in Querétaro, Mexico. In 2017, when it was still operating as Chassis Brakes International, the company opened a completely new plant there.

Mastering global challenges with worldwide on-site support

“Brakes are among the most critical safety features of every vehicle, and they need to operate perfectly under all circumstances,” Hubert Klehenz points out. In order to meet the high quality, safety and reliability requirements, brake manufacturers machine each part with the greatest care. “We receive the unfinished parts for brackets and brake calipers made of aluminium and cast-iron and take care of the entire machining and assembly process.”

In doing this, Hitachi Automotive Systems Group needs to eliminate all conceivable potential errors in order to ensure that none of their products are faulty. This approach is used across the board in the automobile industry and is the reason that the brakes in modern cars almost never fail. However, it does lead to increasing expenditure in terms of the equipment and tools used in brake manufacturing. Only components and processes that have been confirmed to rule out failures are used.

Focusing on core competencies

After the runaway success of their partnerships in Poland and Turkey, Hitachi Automotive Systems Group decided to continue working with the precision tool manufacturer in Mexico as well. “MAPAL’s structure is similar to ours, which enables them to support us at a regional level,” says Klehenz. “On top of that, MAPAL offered us a ready-made solution for implementing the operations at our factories.”

All-round Tool Management

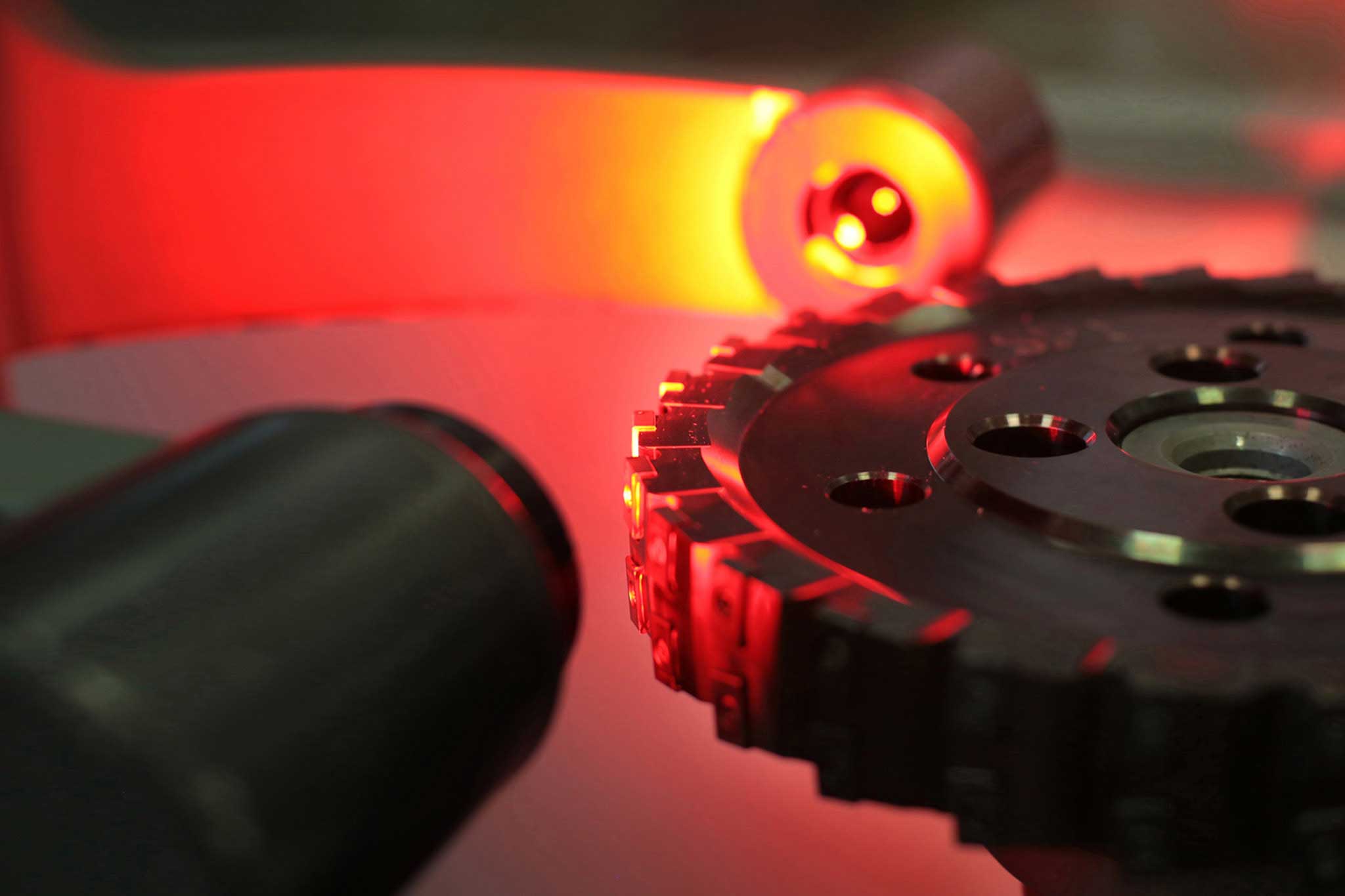

At Querétaro, MAPAL implemented – and continues to implement – all the components of the modular tool management system. Amongst other things, it installed its own UNIBASE-M tool dispensing system, as well as a UNISET-C setting fixture. On top of that, as in Turkey and Poland, the MAPAL service includes a complete tool-setting area. “We make use of the complete service, from the procurement of various consumables – including the tools – all the way through to the dispensing of materials and stock monitoring with automatic re-ordering. MAPAL also takes care of the setting and installation of the tools. When we receive the tools, they’re already on the machine and ready for operation,” Hubert Klehenz explains. MAPAL is also responsible for all regrinding and reconditioning procedures.

And that’s just the tip of the iceberg when it comes to tool management: “While all this is going on, MAPAL constructs tools and chucks that perfectly match our manufacturing standards and make high-performance, economical production possible.” For example, MAPAL is continually working on ways to help Hitachi Automotive Systems Group to reduce cycle times and increase production outputs.

Tool Management 4.0 – an impressive service

Hubert Klehenz is pleased: “Tool Management 4.0 has definitely given us a boost when it comes to digitalisation and all its benefits for manufacturing.” He says that the direct transfer of information makes a difference – for example in the automatic restocking of inventory, which ensures that all necessary materials are available. “We have significantly more flexibility when replacing tools. As a result, the machines have noticeably less downtime,” says Klehenz, naming just one of the benefits. On top of that, Hitachi Automotive Systems Group can now digitally track its tools and receive automated reports about them.

“Having MAPAL as our tool manager gives us maximum transparency across all locations in terms of technology and machining processes – and in terms of cost,” says Klehenz. MAPAL calculates the cost per part for tool management at Hitachi Automotive Systems Group.

- No more difficulties finding the right tool when you need it;

- Completely accurate stock inventories – which has a positive effect on purchase costs and tied-up capital;

- More resources for activities that add value – like brake installation – as MAPAL manages the set-up and adjustment of tools;

- Each plant regularly receives its own key figures, making it possible to monitor the costs and outputs of individual machines;

- Productivity is increased as a result of amendments made on the basis of these figures;

- Hitachi Automotive Systems Group has access to the newest technologies when it comes to tools and their applications;

- MAPAL takes care of the reconditioning of the tools, leading to a longer service life and higher maintenance efficiency.

Global and local cooperation

During day-to-day operations on site, the company’s production managers meet regularly with the MAPAL employees. Together, they discuss the production schedule and analyse the most important key figures. These include machine and tool failures, output figures and productivity. Every year, there are workshops at the three factories in Mexico, Poland and Turkey to share best practices and harmonise processes across the different locations. Having all the data digitally recorded by c-Com facilitates is a great help.

And cooperation is going to be significantly increased in the future: “We are now going to assess additional locations and units to identify where a similar tool management system would be helpful and increase efficiency,” says Klehenz. In doing this, the three current locations will act as model plants providing evidence of the increased efficiency.