Ingegneria aerospaziale

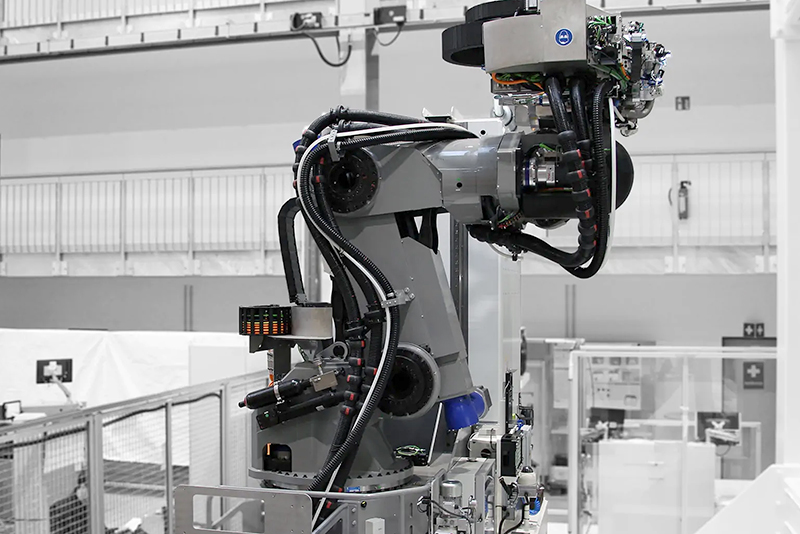

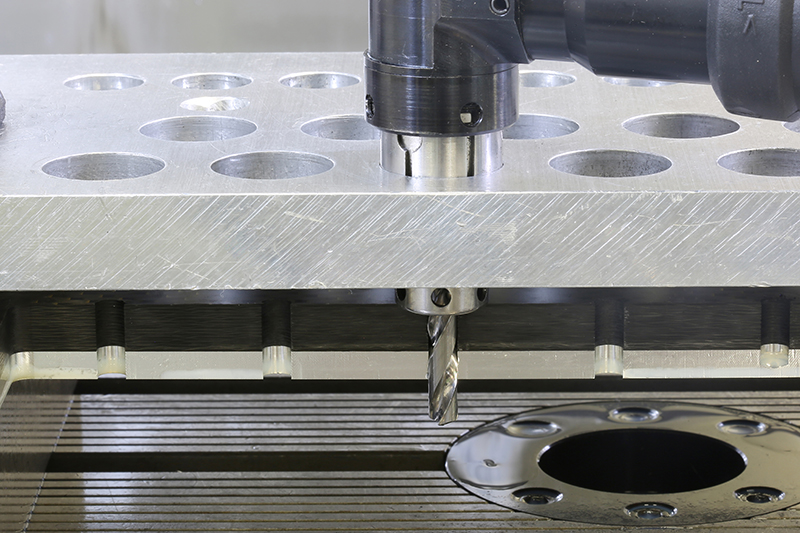

I materiali altamente resistenti e leggeri allo stesso tempo hanno un ruolo centrale nell’aeronautica. La combinazione di materiali innovativi contribuisce a ridurre il peso, aumentare la robustezza e la resistenza alla corrosione e semplificare l’assemblaggio grazie a un design integrativo. Mentre i componenti strutturali in alluminio, titanio o acciai ad alta resistenza vengono processati su centri di lavorazione o macchine a portale, l’assemblaggio finale viene eseguito da macchine a guida manuale, unità di avanzamento o robot.

Produzione di pezzi singoli

Nella produzione di pezzi singoli, i componenti sono lavorati in modalità stazionaria, ovvero in una macchina con uno o più serraggi. Mentre i componenti cubici di piccole-medie dimensioni sono processabili in un centro di lavorazione, quelli di grandi dimensioni richiedono macchine a portale specifiche.

- Usinage du titane par enlèvement de copeaux

- Usinage de l'aluminium

- Matériaux composites et plastiques

最终装配

基于尺寸规模,在进行飞机的最终装配时,仍然采用手持式设备。例如:在我们所称的总装线(FAL)中,铆钉孔是在飞机机身的外壳中加工出。这些工具设计有特殊的导向元件。

Latest news in the aerospace sector

-

24.10.2025

Portrait: MAPAL Centre of Competence PCD tools

With the Centre of Competence for PCD tools, MAPAL sets standards in customer service, technology, efficiency and sustainability.

-

15.10.2025

Successful tooling solutions from MAPAL increase productivity for customers.

Increasing customer productivity is at the heart of MAPAL’s standard processes for the industrial manufacturing of strategic components.

-

06.10.2025

Innovations and solutions of MAPAL

MAPAL presents its 2026 innovations and solutions in a comprehensive brochure.